Recent News

Past News

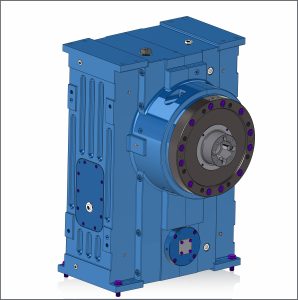

Davis-Standard is pleased to introduce its next-generation gear reducer. This sleek new design represents a commitment to customer feedback, field experience, and technical engineering while building upon the robust performance synonymous with Davis-Standard gear reducers. The new reducer fulfills a variety of extrusion requirements, including those with high and low torque, speeds and extrusion pressures. It can also accommodate the DS Activ-Check™ system, Davis-Standard’s Industry 4.0 platform for continuous monitoring, preventative maintenance and mobile alerts.

Davis-Standard is pleased to introduce its next-generation gear reducer. This sleek new design represents a commitment to customer feedback, field experience, and technical engineering while building upon the robust performance synonymous with Davis-Standard gear reducers. The new reducer fulfills a variety of extrusion requirements, including those with high and low torque, speeds and extrusion pressures. It can also accommodate the DS Activ-Check™ system, Davis-Standard’s Industry 4.0 platform for continuous monitoring, preventative maintenance and mobile alerts.

“Our next-generation reducer represents strategic engineering and the application of cumulative knowledge to deliver greater functionality without compromising performance,” said Gary Peacock, Davis-Standard’s director of engineering. “We’ve improved all major components and packaged them in a redesigned housing. We already have hundreds of extruders fitted with the new reducer in the field. Customers across all Davis-Standard applications are pleased with the results.”

The new gear reducer is available in five different dimensions and capacities for extruders ranging from 2 inches (50mm) to 6.5 inches (165mm) in size. Following is a summary of advantages:

Horizontal and vertical orientations – The horizontal orientation is a good fit for belt-driven machines and/or low centerlines. This allows for a range of belt drives, versatile feedscrew timing, and adaptability to direct-coupled drives. The vertical housing arrangement is designed for direct-coupled and narrow footprint machines. It allows for tight positioning of extruders used in multilayer processes.

Cooling and lubrication – There are two cooling and lubrication options based on housing style and customer requirements. These include oil bath lubrication and partial immersion/forced lubrication.

Gears and roller bearings – Case-hardened precision ground helical gearing is available in a wide range of gear reduction ratios to suit process requirements. New to this reducer series are spherical roller thrust bearings which absorb the axial process load and provide a self-centering, compact design with superior low-friction characteristics.

Radial shaft seals – All reducers are fitted with high-quality, spring-loaded radial shaft seals to contain lubrication oil and exclude contaminants.

Felt excluder – A felt ring excluder has been added to the front output shaft to protect the shaft and seal from abrasion and extend seal life.

Housing design – Durable cast iron construction provides quiet operation and minimal vibration. Large inspection ports simplify viewing of gear tooth condition, and a non-vented, bullet-type oil sight check eliminates the potential for leakage. Large oil fill ports allow for easier filling, while a low point drain port enables complete draining. A front thrust shaft cover completely encloses the reducer housing, allowing for more precision seal-to-shaft alignment.

Retrofitting to older machines – There are many opportunities to retrofit the Next Gen gearcase to older extruders. Please contact Davis-Standard’s Aftermarket team to see if this applies to your existing machines.

For more information about the new gear reducer, contact marketing or visit our contact us page to submit your inquiry.

Davis-Standard is pleased to announce that Markus Lehmann has been appointed area sales manager, representing Davis-Standard’s German subsidiary ER-WE-PA GmbH. In his new role, Markus will be responsible for capital equipment and converting machinery sales in Austria, Denmark, Germany, Italy, Portugal, Switzerland and the United Kingdom, as well as the Benelux, Middle Eastern and Scandinavian regions.

Davis-Standard is pleased to announce that Markus Lehmann has been appointed area sales manager, representing Davis-Standard’s German subsidiary ER-WE-PA GmbH. In his new role, Markus will be responsible for capital equipment and converting machinery sales in Austria, Denmark, Germany, Italy, Portugal, Switzerland and the United Kingdom, as well as the Benelux, Middle Eastern and Scandinavian regions.

Markus brings more than 28 years of experience to this position, having worked at Reinhardt Technik GmbH, Atlas Converting, Kampf, Nordson, Stepah Technology BV and EMG Automation GmbH, among others. He has extensive technical knowledge in supporting customers with solutions-based technology that promotes efficiency, high outputs, and sustainability goals. Markus has a degree in mechanical and industrial engineering from the University of applied science in Cologne, Germany.

For more information about Davis-Standard’s converting machinery capabilities visit here.

Davis-Standard will promote the company’s liquid and extrusion coating machinery at booth #111 during Converter’s Expo, April 26 – 27, at Lambeau Field Atrium in Green Bay, Wisc. The complementary portfolio of Deacro Industries, a Davis-Standard Company, will be featured at booth #112. Davis-Standard will highlight standard and tailored liquid coating lines for window and paint protection, specialty products, PSA and silicone release liners, and inline and offline unwind and winding options for diverse applications.

With more than 50 standard and custom liquid coating machinery options, Davis-Standard assists customers with achieving desired output and quality characteristics for their products. Applications include tapes and labels, silicone-coating products, paint protection films (PPF), and specialty coating markets. Davis-Standard can address low to high-speed applications, narrow and wide applications, simple lines with a dedicated coater, as well as complex coating lines with multiple cartridge coaters. In addition, equipment audits are available to upgrade existing machine configurations for processing a range of materials used in film and flexible packaging, construction, automotive, and medical applications.

In the growing area of PPF, Davis-Standard offers a complete system with both extrusion and solution coating components. This system utilizes Davis-Standard’s versatile Series 4000 cartridge coater with advanced drying and laminating technology, and winding and unwinding capabilities for producing high-quality PPF films. Other system advantages include: a dual-direction turret unwind/splicer; turret stripper winder; coater enclosure; dual-direction turret winder and roll changer; and Integrator PRO supervisory control.

For extrusion coating and laminating processes, Davis-Standard engineers laboratory-size systems for R&D all the way up to five-meter-wide systems for diverse applications. Each is designed to address precision gauge control, splice speed, simplified changeovers, better adhesion properties, high-speed transfer, and operator safety. All equipment, including extruders, controls, coaters and laminators, winders and unwinders, is engineered for reliability, minimal waste and consistent performance. Expertise in automatic profile control (APC), deckle and die design, multi-coating, web handling, transfer unwinds and winders supports customer profitability.

To accommodate an existing carriage or platform structure, Davis-Standard’s CHP extruder provides a smaller footprint and lighter weight machine option. Customers benefit from a space-saving retrofit or coextrusion addition in order to boost outputs and line speed. This includes efficient mixing capabilities for a low melt temperature and output rates that are 80 to 100 percent higher than current alternatives.

Deacro’s slitter rewinder machinery is widely used for applications in food packaging, medical packaging, industrial products, pressure-sensitive labels, and others. This includes salvage rewinders, slitter rewinders, turret slitters, and core cutters. Unique to Deacro are roll lock differential air shafts, closed-loop rewind tension control and auto core placement to improve processing efficiency. Deacro also excels in automation to reduce set-up times, minimizing roll loading times between finished sets, simplify maintenance, and streamline roll packaging. Existing manual slitter rewinders can be upgraded with automated technology to improve performance.

One of Davis-Standard’s most exciting developments is the launch of its DS Activ-Check™ system. DS Activ-Check™ is an Industry 4.0 platform for continuous monitoring, preventative maintenance, and mobile alerts. DS Activ-Check™ uses analytical tools based on long-term cloud data storage, along with process and equipment technology algorithms, to help management and production teams identify and improve product quality and line productivity.

Click here for more information about extrusion and liquid coating equipment options prior to the show. For Deacro Industries, visit https://www.deacro.com/.

Davis-Standard is pleased to exhibit at the WAI Operations Summit and Wire Expo at booth #704, June 7-8, in Dallas, Texas. The company will highlight wire and cable solutions that support applications in the aerospace, automotive, power cable, construction, and communication industries. This includes aerial cable, building wire, coaxial and composite cable, video pair cable, CATV, THHN and THWN products.

Davis-Standard’s wire and cable industry leadership spans more than seven decades. Wire and cable equipment is engineered according to customer specifications, including extruders, payoffs and take-ups, accumulators, cooling systems, and capstans. This includes complete machinery solutions for high-temperature aerospace wire, low-voltage automotive cables, fiber optic cables and ducts that improve connectivity, and high-output applications involving multi-layer constructions such as nylon over PVC, among others. Requirements for line speed, conductor type, insulating materials, wall thickness range, and outside diameter are addressed with technical expertise and consistent results. Feedscrew and control technology, extruder efficiency, single reel shaftless payoffs, dual flyer payoffs, multi-pass and belt wrap capstans, and dual reel take-ups are a few examples of how Davis-Standard supports customer profitability. These capabilities are further augmented by the extensive equipment portfolio offered by Maillefer, a Davis-Standard company.

One of Davis-Standard’s latest developments is the launch of its DS Activ-Check™ system. DS Activ-Check™ is an Industry 4.0 platform for continuous monitoring, preventative maintenance, and mobile alerts. DS Activ-Check™ uses analytical tools based on long-term cloud data storage, along with process and equipment technology algorithms, to help management and production teams identify and improve product quality and line productivity. The use of digital transformation to strengthen operations has shown significant potential in the extrusion sector, including wire and cable processes.

For information prior to the show

Lou Piffer of Davis-Standard will present two papers during the TAPPI 2022 International Flexible Packaging and Extrusion Division Conference, April 10 – 13, in Austin, Texas. Piffer, a senior sales engineer and specialist in cast film and extrusion coating, will present during sessions 9 and 10 during the conference.

Lou Piffer of Davis-Standard will present two papers during the TAPPI 2022 International Flexible Packaging and Extrusion Division Conference, April 10 – 13, in Austin, Texas. Piffer, a senior sales engineer and specialist in cast film and extrusion coating, will present during sessions 9 and 10 during the conference.

Piffer’s presentation during session 9 on Tuesday, April 12, is entitled “Polymers: Films and Extrusion Coating Lines.” This paper encompasses the work of industry expert Dragan Djordjevic from the 1990s and is part of the session’s focus on timeless technical insights. The presentation will cover standard rheology variables such as melt index, molecular weight distribution, density, and side-chain branching. The variables will be reviewed not only as an academic quality, but from the perspective of how a unique combination permits viable processing on a cast film or extrusion coating line. This includes a discussion on determining important end-use properties in the melt and solid-state of the resin.

His presentation during session 10 on Wednesday, April 13, is entitled “Extrusion Coating versus Adhesive Lamination – A Comparison Study.” This paper builds upon Piffer’s earlier work entitled “Extrusion Coating in an Adhesive Lamination World,” to further examine the advantages and disadvantages of both processes for specific structures. He will outline various requirements for an acceptable structure and discuss how those features can be maintained when running an adhesive lamination structure using the extrusion coating process.

To see the full conference agenda, visit https://events.tappiflexible.org/program/technical-program/

Davis-Standard, LLC will exhibit production of two-lumen “Double D” thermoplastic elastomer (TPE) catheter tubing at booth 4024 during MD&M West in Anaheim, Calif., April 12-14, 2022. The line will also demonstrate 1.75mm filament made of polylactic acid (PLA) biopolymer, which will be used in a 3-D printer operating at the booth. Davis-Standard will exhibit the line’s capabilities in conjunction with technology partners Conair Group and Zumbach Electronics.

Davis-Standard, LLC will exhibit production of two-lumen “Double D” thermoplastic elastomer (TPE) catheter tubing at booth 4024 during MD&M West in Anaheim, Calif., April 12-14, 2022. The line will also demonstrate 1.75mm filament made of polylactic acid (PLA) biopolymer, which will be used in a 3-D printer operating at the booth. Davis-Standard will exhibit the line’s capabilities in conjunction with technology partners Conair Group and Zumbach Electronics.

“This line is an excellent example of a space-saving system that can be used for both medical and industrial tubing. We also have numerous larger scale lines like this one in the field, capable of running in excess of 800 feet per minute,” said Kevin Dipollino, Davis-Standard’s Senior Product Manager of Pipe, Profile and Tubing Systems.

The line features a Davis-Standard 1-inch MEDD Series (Medical Extruder Direct Drive) extruder. The extruder’s key features include interchangeable barrel assemblies and replaceable feed-section liners for multiple materials and applications. Easy-to-clean stainless-steel surfaces, a direct drive motor, simplified maintenance, and operator accessibility are other key advantages for medical cleanroom environments.

The MEDD extruder will be equipped with a DS-eVUE process control featuring a 19-inch (480mm) high-resolution touch-screen. This Windows®-based controller is designed for mid-range processes with advanced supervisory functions such as event logging, customized reports, SQC, historical trending, troubleshooting and pressure set-up. Operators benefit from a complete line overview, detailed extruder data, recipe creation and storage, and multi-level security to protect settings and accessibility. DS-eVUE can interface with the majority of existing PLC controls and includes Davis-Standard’s ReACT (Remote Access Technology) support program for real-time, remote service and troubleshooting.

On Tuesday and Wednesday, April 12 and 13, the line will exhibit processing of PLA. The melt from the extruder will pass through a cross-head filament extrusion die and a non-contact calibrator into the Conair HTMP multi-pass vacuum sizing/cooling tank. This tank is a space-saving innovation that enables the extrudate to follow a Z-shaped path in a compact 12-foot design with the same cooling equivalent as a 30-foot tank. Other advantages include Zumbach OD gauge control, a Conair Medline® puller and Conair ATC series colier set up with multiple spools on the coiling shaft. A floor-mounted ultrasonic loop sensor monitors the incoming product, automatically adjusting coil speed and traverse motion to wind product smoothly.

On Thursday, April 14, the line will shift production over to the dual-lumen “Double D” TPE catheter tubing. In addition to the MEDD extruder and Conair upstream and downstream equipment, the line will include a Zumbach ultrasonic wall-thickness gauge. This line will showcase components for efficient processing from start to finish, including the advantages of Zumbach gauges in monitoring and reporting changes in wall thickness on the control screen as the tubing cools. This also provides data used to regulate the puller speed and cooling tank vacuum to maintain critical tubing dimensions over a production run.

Davis-Standard representatives at the show will include Kevin Dipollino, Joe Wnuk, and Jason Baird.

For more information about the show, visit www.mdmwest.com.

Schedule an appointment at the show - click here.

![]() Did you know you can take advantage of comprehensive product development at one of Davis-Standard’s technology centers? Contact us today to learn more.

Did you know you can take advantage of comprehensive product development at one of Davis-Standard’s technology centers? Contact us today to learn more.

![]() We also offer 24/7 after-sales support, troubleshooting, and service by calling +1 844-MYDAVIS.

We also offer 24/7 after-sales support, troubleshooting, and service by calling +1 844-MYDAVIS.

SCG Chemicals, the parent company of Thai Polyethylene, is one of Thailand's largest integrated petrochemical companies. The company offers products ranging from upstream production of olefins to downstream production of polyethylene and polyvinyl chloride. The installation of the Davis-Standard lab line at their facility in Rayong, Thailand, aligns with the company’s commitment to developing new technology that creates high value-added products (HVA) and service solutions for customers worldwide.

Niwat noted that Covid restrictions and measures made commissioning a challenge. But through a lot of hard work, communication and feedback, Davis-Standard collaborated with them to get it done. “Our teams did an excellent job of working through various Covid-related issues and changes during the process. Davis-Standard’s on-site service teams were professional and experts in their field.”

Davis-Standard offers one of the industry’s largest and most versatile extrusion coating and laminating platforms, including customization based on customer requirements. ER-WE-PA GmbH, specializes in technology for aseptic packaging film and worked with Thai Polyethylene on this project.

“The innovation being delivered on this new line is significant for Thai Polyethylene’s customer base,” said Daniel Schiller, area sales and project manager for Davis-Standard. “Working alongside their team has been rewarding. We look forward to supporting them as they expand their product offering.”

For more information about Thai Polyethylene and SCG Chemicals, visit www.scgchemicals.com. For more information about Davis-Standard’s converting and extrusion coating solutions, click here.

Have questions or want to inquire about a product or service? Contact us!

Davis-Standard is pleased to announce that Matthew Urban has been hired as Capital Equipment Sales Manager for the TSL (Thermoforming Systems, LLC) product line. In this role, Urban will be responsible for global sales of TSL’s sheet and thermoforming technology primarily used for food and beverage end markets. TSL offers customers pellet-to-product solutions with a portfolio of formers, trim presses and rotary machinery, as well as in-line extrusion capabilities.

Davis-Standard is pleased to announce that Matthew Urban has been hired as Capital Equipment Sales Manager for the TSL (Thermoforming Systems, LLC) product line. In this role, Urban will be responsible for global sales of TSL’s sheet and thermoforming technology primarily used for food and beverage end markets. TSL offers customers pellet-to-product solutions with a portfolio of formers, trim presses and rotary machinery, as well as in-line extrusion capabilities.

“Matthew understands thermoforming equipment and the customers we serve,” said Roger Moore, VP of Sales for TSL. “His leadership abilities and experience, knowledge of the industry, and commitment to service will be an asset to our market development efforts.”

Urban comes to Davis-Standard from SencorpWhite where he was an executive account manager for the company’s thermoforming product line. He served customers in the consumer products, medical, food, cosmetic, and packaging markets throughout the U.S., Mexico and Europe. He has a bachelor of science in consumer studies from Virginia Tech and is a member of SPE.

For more information about the TSL product line, visit www.tslusa.biz.

Have questions or want to inquire about a product or service? Contact us!

Davis-Standard’s extrusion and converting teams look forward to their first annual? PTXPO (Plastics Technology Expo), March 29 – 31, in Rosemont, Ill. Located in booth #4106, Davis-Standard will promote new and existing technologies encompassing blown film, cast film, pipe, profile and tubing, and sheet machinery. The includes the new DS Activ-Check™ cloud-based platform and the company’s range of aftermarket services.

Davis-Standard’s extrusion and converting teams look forward to their first annual? PTXPO (Plastics Technology Expo), March 29 – 31, in Rosemont, Ill. Located in booth #4106, Davis-Standard will promote new and existing technologies encompassing blown film, cast film, pipe, profile and tubing, and sheet machinery. The includes the new DS Activ-Check™ cloud-based platform and the company’s range of aftermarket services.

In addition, Steve DeAngelis, Davis-Standard’s vice president of sheet, fiber, foam and reprocessing, will give a presentation on Wednesday, March 30, from 1:00 to 1:30 p.m. in the Plastics Processing Technology Theater. His talk entitled, “Introduction to the XP Express® Active Gravity Touch (AGT),” will outline the design advantages of Davis-Standard’s new rollstand for processors of both rigid and flexible packaging. DeAngelis will compare the AGT model to conventional rollstand designs and describe the benefits of AGT’s increased automation and roll control. The presentation will include a discussion on upstream extruder arrangements, requirements for sheet versus film process, and advantages of various roll orientations.

Following is a summary of highlights for Davis-Standard product groups represented at the show.

In blown film, Davis-Standard has seen steady demand for solutions in high-barrier food packaging, agricultural films, geomembrane, stretch film, printing and laminating films, flexible packaging, collation shrink films, and stretch hooders. For films that require enhanced clarity and flexibility, Davis-Standard offers the Aquafrost® water-quench system. Other options include industry-leading Vector® air rings, DSB® feedscrew designs, Streamlined Coextrusion Die (SCD®), and Optiflow and Vertex dies, each designed to process specific films.

Davis-Standard’s cast film group supports customers in hand and machine wrap, CPP films, barrier films, consumer and medical packaging, food packaging, and lab-scale equipment. Davis-Standard offers high barrier cast film capabilities for diverse barrier structures for seven, nine, eleven, or more layers. Extruders are mounted on a platform above the casting unit, and technology can be engineered to support a range of resins, including PA, PE, mPE, PP, PET, EVOH, and tie structures. Processors can attain finished web widths from 2000mm to 3600mm, line speeds up to 150 meters per minute, web thickness from 75 to 300 microns, and a max roll diameter of 1200mm.

Specific to pipe, profile, and tubing, Davis-Standard will market its newly introduced SHO (Super High Output) extruder. As the latest addition to Davis-Standard’s groove feed product line, the SHO extruder delivers outputs 20 percent higher than existing groove feed models. Designed with a compact footprint, it is engineered with an improved feed section and high-performance, energy-efficient DSB® barrier screw. This is especially beneficial for high-viscosity HDPE applications such as pipe extrusion, where lower melt temperatures, reduced power consumption, and improved energy efficiency are essential.

In sheet, Davis-Standard is excelling in high-output packaging, industrial thick sheet, appliances, and medical markets. A recent addition to the company’s sheet portfolio is the XP Express®- AGT (Active Gravity Touch) roll stand, which is the focus of Steve DeAngelis’ presentation. This design supports the full range of sheet and cast applications and is available in three options depending on requirements. Each has a fully automated multi-roll gap nip, individual roll speed and temperature control, enhanced heat transfer, and an adaptable pull-roll design. This is augmented by a four-point Y-axis and traverse X-axis control to further support operator functionality. Uniform cooling on both sides, double polishing capabilities, reduced web stress, and consistent web orientation and thickness control foster high-quality, flat sheet with desired clarity.

One of Davis-Standard’s most exciting developments is the launch of its DS Activ-Check™ system. DS Activ-Check™ is an Industry 4.0 platform for continuous monitoring, preventative maintenance and mobile alerts. DS Activ-Check™ uses analytical tools based on long-term cloud data storage, along with process and equipment technology algorithms, to help management and production teams identify and improve product quality and line productivity.

Davis-Standard’s aftermarket services continue to be instrumental in supporting customer success. This includes performance audits to determine potential upgrades to improve output rates, processing efficiency, and bottom-line profitability. In addition, Davis-Standard’s ability to service equipment for nearly every extrusion and converting application, plus non-Davis-Standard brands, is advantageous to customers worldwide. This includes an extensive spare parts inventory, timely 24/7 customer service, global technical capabilities, and rebuild and retrofit services.

Contact us to schedule an appointment at the show!

Davis-Standard, LLC will market the company’s nonwovens and converting solutions technology at booth #2604 during Techtextil North America on May 17- 19, 2022, in Atlanta, Georgia. Davis-Standard offers a range of performance technology for high-volume fabric coating applications and engineered textile composite applications. This includes extruders, controls, feedscrews, unwinds and winders, laminators, extrusion coaters, and web handling equipment. Davis-Standard will also promote the company’s new DS Activ-Check™ cloud-based platform as well as R&D opportunities.

In the area of fabric coating, Davis-Standard will highlight its high-output CHP extruder. This extruder offers flexibility and added functionality via feedscrew and other extruder station-related changes for different high volume market applications. High volume applications include lumber wrap, underlayment, house wrap, membranes, industrial goods packaging, and industrial food packaging. Processors can extrude LDPE, LLDPE, and PP blends in a variety of structures with in-line speeds up to 1500 feet per minute (450 mpm) and web widths up to 160 inches (4 meters). The CHP accommodates existing carriage or platform structures and can easily fit into tight spaces for retrofits, coextrusion additions, and as a replacement extruder to increase output and line speed. Rates are 80 to 100 percent higher than conventional extruders with improved quick-change capabilities and reduced purge time.

Davis-Standard’s in-line extrusion coating and laminating machinery supports consistent and reliable adhesion for high-value engineered textile composite applications. Applications include chemical-resistant garments, footwear, protective outerwear, and multiple products for the aviation, marine, and membrane industries. Davis-Standard’s coaters and laminators can support widths up to 126 inches (3.2 meters), line speeds up to 330 feet per minute (100 mpm), and roll diameters up to 40 inches. This includes technology for PET and PA woven substrates with TPU, TPO, PA, and Hytrel blends. In addition, coaters are capable of coating one or both sides of the web for product adaptability. Applying the primer in-line has been advantageous in helping converters avoid a secondary process while also providing in-house quality control and intellectual property protection.

Davis-Standard has demonstrated expertise in designing machinery for the circular economy. This includes mono-material structures, biodegradable resins, increasing recycled content, adding functionality with twin-screw technology, edge trim recycling, and energy-saving design features.

With more than 50 standard and custom liquid coating products, Davis-Standard is experienced in attaining the right viscosity, emulsion, pH, and adhesive characteristics for customer applications. This includes tapes and labels, silicone-coating products, paint protection films (PPF), and specialty coating markets. The company can address low to high-speed applications, narrow and wide applications, simple lines with a dedicated coater, and complex coating lines with multiple cartridge coaters.

One of Davis-Standard’s most exciting developments is the launch of its DS Activ-Check™ system. Davis-Standard’s Industry 4.0 platform for continuous monitoring, preventative maintenance and mobile alerts. DS Activ-Check™ uses analytical tools based on long-term cloud data storage, along with process and equipment technology algorithms, to help management and production teams identify and improve product quality and line productivity. Customers can run trials using DS Activ-Check™ at Davis-Standard’s R&D facility in Pawcatuck, Conn.

Wish to make an appointment at Techtextil before the show? Contact us today.

Want to learn more about our converting solutions? Visit here.

James (Jim) Murphy Elevated to Vice Chairman of the Davis-Standard Board of Directors; Brian Marston, William (Bill) Barker and John McGrath Elected as Members of the Davis-Standard Board of Directors

PAWCATUCK, Conn.--(BUSINESS WIRE)--Giovanni Spitale has been named Chief Executive Officer of Davis-Standard, a portfolio company of Gamut Capital Management. Mr. Spitale replaces Jim Murphy who has been elected as Vice Chairman of the Board of Directors. In addition, Davis-Standard has elected several individuals as members of its Board of Directors, including Brian Marston, Bill Barker and John McGrath, each of whom have significant experience within Davis-Standard’s markets.

“I am extremely excited to join the Davis-Standard organization,” said Mr. Spitale. “Having spent considerable time in the polymer processing and broader capital equipment industries, I have long admired Davis-Standard’s leading position in the market, its unmatched engineering capability and the Company’s reputation as a strong partner to its customers through both original equipment and aftermarket support. I look forward to working with the Davis-Standard organization to continue to grow the business globally and support our world-class base of customers with differentiated product offerings and services.”

“I want to thank the entire Davis-Standard organization for the many years of strong performance that we have collectively executed upon under my tenure as CEO,” said Mr. Murphy. “I am thrilled to continue to serve the Company as Vice Chairman of the Board of Directors and look forward to collaborating with Giovanni alongside the broader Board of Directors in this next and very exciting phase of Davis-Standard’s long history.”

Mr. Spitale previously was Vice president of Commercial Parts within Boeing Global Services. In this role, Spitale had full responsibility for the profit and loss management, and strategic direction of Boeing’s $4 billion portfolio of commercial aircraft and engine parts businesses. Prior to his tenure at Boeing, Mr. Spitale was President of Customer Service and Support at Milacron.

Alongside Mr. Spitale and Mr. Murphy, the Davis-Standard Board of Directors includes Dan Guthrie, Chief Operating Officer of Davis-Standard, representatives from controlling shareholder Gamut Capital Management, as well as Brian Marston, Bill Barker and John McGrath. Mr. Marston is currently President & CEO of Uniloy and was previously President of the Blow Molding and Extrusion businesses of Milacron. Mr. Barker was previously the President and CEO of Mold-Masters. Mr. McGrath was previously the CEO of Pactiv Evergreen.

About Gamut Capital Management

Gamut Capital Management is a New York-based private investment firm managing $1.5 billion in assets focused on the middle market. Founded in 2015, Gamut’s senior deal professionals have executed investments in over 50 companies in North America and Europe. To learn more, please visit www.gamutcapital.com.

Have questions about this release? Please email marketing.

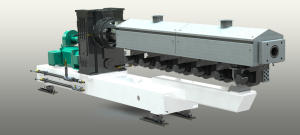

Equipment solutions for Asia’s high-growth markets will be promoted by Davis-Standard, LLC in Hall 2.1, booth #F151 during Chinaplas 2022, April 25–28, in Shanghai. This includes technology in blown film, cast film, compounding/recycling, extrusion coating, foam, liquid coating, pipe, profile and tubing, sheet, elastomer, winding and unwinding. Davis-Standard will exhibit an HPE-075H 24:1 extruder, which is an example of the company’s high-performance extruder range for coextrusion and multi-layer applications.

Davis-Standard’s installed base in Asia continues to grow as do vertical opportunities in aftermarket upgrades and options that improve efficiency, performance, and long-term sustainability. Davis-Standard (Suzhou) Machinery has been central to all efforts in the region with machine building and assembly, inventory and aftermarket support, field service and installations.

Exhibit Highlights

Specific to pipe, profile and tubing, Davis-Standard will promote its MEDD and SHO extruders and Maillefer their product line supporting several applications.

The compact MEDD (Medical Extruder Direct Drive) is built with a replaceable feed section liner and direct drive technology for greater efficiency and materials flexibility. Davis-Standard offers a high-tech melt pump system to maximize stability when processing sensitive materials. It is ideal for medical tubing and industrial tubing applications that require a cleanroom environment.

The SHO (Super High Output) extruder is the latest addition to Davis-Standard’s groove feed technology. The SHO delivers outputs 20 percent higher than existing groove feed models. It is engineered with an improved feed section and high-performance, energy-efficient DSB® barrier screw. This is especially beneficial for high-viscosity HDPE applications such as pipe extrusion, where lower melt temperatures, reduced power consumption and improved energy efficiency are essential.

Maillefer’s pipe and tube extrusion systems support markets encompassing medical, blown fiber micro duct, heating and plumbing, automotive, micro-drip irrigation, on- and off-shore flexibles, and other specialty and technical goods. These systems are engineered to provide value that makes a difference. Blown film microduct destined for FTTx data networks, multi-layer PEX-AI-PEX composite pipe for heating and plumbing, and multi-functional tubing for automotive applications are examples of the production capacity available from the Maillefer portfolio.

In extrusion and liquid coating, Davis-Standard has demonstrated expertise in designing machinery for the circular economy. This includes mono-material structures, use of biodegradable resins, increasing recycled content, adding functionality with twin-screw technology, edge trim recycling systems, and energy-saving design features.

For extrusion coating, Davis-Standard collaborates with customers to address precision gauge control, splice speed, simplified changeovers, better adhesion properties, high-speed transfer, and operator safety. In liquid coating, the focus is on helping customers attain the right viscosity, emulsion, pH, and adhesive characteristics for their products. Applications include tapes and labels, silicone-coating products, paint protection films (PPF), and specialty coating markets.

Davis-Standard technology specific to the Asian marketplace is the dsX flex-pack™ 300S. This single station extrusion and lamination line is a collaboration between Davis-Standard’s design teams in the U.S., Germany and China. The 300S can support web widths from 650 to 1,350mm and is engineered for processing rates up to 300 meters per minute for paper, film, and aluminum foils with direct gravure primer coating and coextrusion lamination stations.

Another example is Davis-Standard’s new stretch film line with DS S3 winder. The line offers a compact machine arrangement, ease of servicing, excellent profile control, consistent roll quality, and an intuitive control package. It is engineered for producing thin films from 31 to 51-gauge (7.8µ to 13µ) at high speeds. The DS S3 winder enables maximum slit widths for hand wrap, machine wrap and jumbo rolls, supporting multiple market segments on one winder.

In sheet, Davis-Standard is excelling in high-output packaging, industrial thick sheet, appliances and medical markets. A new addition to Davis-Standard’s sheet line-up is the XP Express®- AGT (Active Gravity Touch) roll stand for the full range of sheet. The roll stand is available in three options depending on requirements. Each has a fully automated multi-roll gap nip, individual roll speed and temperature control, enhanced heat transfer, and an adaptable pull-roll design. This is augmented by a four-point Y-axis and traverse X-axis control to further support operator functionality. In addition, uniform cooling on both sides, double polishing capabilities, reduced web stress, and consistent web orientation and thickness control promote high-quality, flat sheet with desired clarity.

Davis-Standard recently introduced the DS Activ-Check™, an Industry 4.0 platform for continuous monitoring, preventative maintenance, and mobile alerts. DS Activ-Check™ uses analytical tools based on long-term cloud data storage, along with process and equipment technology algorithms, to help management and production teams identify and improve product quality and line productivity.

For more information about Chinaplas and to add Davis-Standard to your show planner.