Recent News

Past News

Davis-Standard is pleased to announce that Ken Vargas has joined the Aftermarket team as Regional Sales Manager – Aftermarket, representing the states of Kansas, Oklahoma, Arkansas, Louisiana, Texas, and Mexico. Vargas will focus on supporting existing installations and new opportunities within this territory, including developing and marketing aftermarket products and services for all Davis-Standard brands.

Davis-Standard is pleased to announce that Ken Vargas has joined the Aftermarket team as Regional Sales Manager – Aftermarket, representing the states of Kansas, Oklahoma, Arkansas, Louisiana, Texas, and Mexico. Vargas will focus on supporting existing installations and new opportunities within this territory, including developing and marketing aftermarket products and services for all Davis-Standard brands.

Vargas comes to Davis-Standard from Coperion Corporation, where he served as a project engineer for material handling modernization. In this role, he helped modernize existing material handling and conveying systems to increase throughputs and production capacity for chemical, oil and gas, food, and mineral manufacturing applications. Vargas holds a Six Sigma Yellow Belt from the American Society for Quality (ASQ) and has a Bachelor of Science in mechanical engineering from the University of Houston.

“Ken brings a proven engineering background and technical expertise to our North American team,” said Joe Guigli, Davis-Standard Vice President of Aftermarket Sales. “His communication skills, understanding of mechanical processes, and knowledge of ongoing systems improvement will be an asset to customers and our aftermarket initiatives.”

For more information about our aftermarket services, please visit our parts and upgrades webpage here.

Davis-Standard will begin its 2022 tradeshow season in Moscow, Russia, at Interplastica, January 25 - 28. In Hall 2.2 at booth D07 in the Swiss Pavillion, representatives from Maillefer and from ER-WE-PA, Davis-Standard’s subsidiary in Germany, will be available to discuss technology for blown film, cast film, extrusion coating, foam, profile, tube, and sheet applications. A specific focus will be Davis-Standard’s dsX™ product line for packaging applications, which provides processing versatility, timely delivery and competitive pricing. Examples of this technology include the dsX™ 400 aseptic packaging line and dsX flex-pack™ 300S flexible packaging line.

The dsX™ 400 aseptic packaging line is a pre-engineered triplex extrusion coating and laminating line for paper, aluminum foils and/or films used in aseptic packaging applications. It is designed for a working width range of 700 to 1,350mm, a mechanical design speed up to 450 meters per minute, and processing speeds up to 400 meters per minute. In addition, the line is equipped with automatic unwind and rewind splicers for speed and processing efficiency. This is a single-source system with Davis-Standard supply of extruders, feedscrews, and extrusion dies to support customer requirements

For lower-speed flexible packaging applications, Davis-Standard offers the dsX™ flex-pack 300S. Proven components and a pre-configured, adaptable machine configuration make this system ideal for converters, printing companies, multi-national companies, and start-ups. It can support web widths from 650 to 1,350mm and process line speeds up to 300 meters per minute for paper, film and aluminum foils with direct gravure primer coating and coextrusion coating lamination stations. Hallmarks of this line include consistent end-product quality, greater uptime and productivity, reduced waste, and application versatility.

To support diverse barrier structures, Davis-Standard offers high barrier cast film capabilities for seven, nine, eleven, or more layers. Extruders are mounted on a platform above the casting unit and are engineered to support a range of resins, including PA, PE, mPE, PP, PET, EVOH, and tie structures. Processors can attain finished web widths from 2000mm to 3600mm, and line speeds up to 150 meters per minute, web thickness from 75 to 300 microns, and a max roll diameter of 1200mm.

Maillefer’s pipe and tube extrusion systems support markets encompassing medical, blown fiber micro duct, heating and plumbing, automotive, micro-drip irrigation, on- and off-shore flexibles, and other specialty and technical goods. These systems are engineered to provide value for multi-layer pipe constructions, with each layer providing functional features and advantages. This includes the use of recycled materials in eco-friendly pipe and tube products.

For questions or inquiries, please contact us.

Peak Nano Films, a U.S.-based nanotechnology leader, recently commissioned a Davis-Standard cast film line for processing a breakthrough dielectric film for capacitor applications. With this new equipment, Peak Nano Films has moved into production to serve automotive, military, electrical grid, and industrial markets. This new nanolayered film represents the first major materials improvement for solid-state film capacitors in decades. Davis-Standard collaborated with Peak Nano’s team to validate the process and tailor cast film machinery based on the company’s unique product requirements.

“We have grown with Davis-Standard throughout this endeavor,” said Mike Hus, Peak Nano Film’s senior vice president of engineering. “Davis-Standard’s technical expertise enabled us to collaborate on new processes and define machinery features prior to purchase. We value Davis-Standard’s experience and systems-oriented approach in helping make this film a reality.”

Peak Nano Films’ modern dielectric film structure overcomes current technology challenges to provide longer capacitor life, higher temperature resistance, greater breakdown strength, and a smaller footprint for capacitor designs. This includes two to four times the energy storage and temperatures up to 150 degrees Celsius (300 degrees Fahrenheit). As a result, capacitor producers benefit from additional design freedom and the potential for reducing systems costs for end-users.

According to Chris Oseredczuk, senior production engineer at Peak Nano Films, the Davis-Standard line is performing well. “We are highly satisfied with the line’s performance and Davis-Standard’s ongoing support. Their sales, technical, parts, and field service teams have provided a timely response during all phases, including initial engagement and acceptance.”

Davis-Standard’s web handling expertise and scrap reduction strategies have been pivotal in helping Peak Nano Films deliver this film and other innovative products. In addition, a custom feedscrew design built specifically to adapt to the process requirements for this dielectric film has also been advantageous.

For more information about Peak Nano Films, visit www.peaknano.com.

For additional information about our cast film products, visit our webpage.

If you'd like to speak with a sales representative regarding our cast film solutions, please contact us.

If there is one theme that captures 2021 for our industry, it is making a strong comeback after an unexpected year in 2020. Across the board, we have seen our industry rebound in equipment sales, application development, improved machinery technology, advances in environmental sustainability, and more. We learned much from the challenges presented by the pandemic, moving forward with renewed purpose in how we do business and creating opportunities for performance-driven innovation. It has been inspiring working alongside you, our customers, as we have forged ahead during a year of significant progress. Thank you for your trust in our ability to provide timely service and equipment technology that supports your processing goals and profitability.

As we enter 2022, we have a positive outlook bolstered by industry-wide gains made over the past year. We anticipate food and protective packaging and agricultural films to remain strong, along with the medical, pipe, telecom, and building/construction markets. We’ll also see an uptick in industrial markets linked to infrastructure and alternative fuel transportation, as well as power markets that support off-shore wind and solar. This is an exciting time to be in our industry! We also recognize that global supply chain delays are affecting all of us and not just our industry. We are doing our best to manage this relative to our needs to support our commitments to you. Our goal is to mitigate delays the best we can by working diligently with our suppliers and being proactive in our approach.

Regarding adjustments post-pandemic, we’ll continue to hire employees to address growth and use virtual tools to support you with troubleshooting and other needs when we cannot address them in person. We also look forward to more in-person tradeshows, events, and conferences. Some shows we’re planning to attend in the first and second quarters of 2022 include Interplastica, Plastindia, Plastimagen, ICE Europe, PT Expo 2022, MD&M West, Chinaplas, and Wire Dusseldorf.

We have exciting news on the technology front, with some of you already taking advantage. Our equipment strategy evolves around industry trends and customer demands. For example, we have seen an increased need for automation to better utilize existing personnel, facilitate operational readiness, and increase production outputs. We’ve also seen more demand for processing bio-materials and mono-material structures to address environmental concerns while also reducing the overall amounts of processed material. We continue to address these trends with highly efficient equipment and feedscrew designs, including equipment with a more compact footprint and the use of the IIoT (Industrial Internet of Things) to provide continuous process monitoring and better performance analytics. We’ve also done our best to keep you informed of trends and best practices through a series of informative virtual seminars and webinars. We hope you’ve been able to take advantage of some of these as they covered a range of relevant topics.

Examples of new technologies introduced in 2021 that address the above are our DS Activ-Check™, XP Express® AGT next generation roll stand, and SHO and CHP extruder series for high outputs.

The DS Activ-Check™ is a custom-designed, cloud-based platform that leverages systems and strategies offered by the IIoT. This tool harnesses digital transformation to simplify complex process data to increase operator effectiveness, leading to reduced downtime, better product quality, and reinforced operator safety. The configurable platform engine uses analytical tools based on long-term cloud data storage along with process and equipment technology algorithms to help management and production teams identify and improve product quality and line efficiency. We anticipate the implementation of this technology to grow in 2022 as the industry fully takes advantage of the benefits of Industry 4.0.

The XP Express®- AGT (Active Gravity Touch) roll stand can be used for both sheet and cast extrusion for the full range of sheet and cast applications. The roll stand is available in three options depending on requirements. Each has a fully automated multi-roll gap nip, individual roll speed and temperature control, enhanced heat transfer, and an adaptable pull-roll design. This is augmented by a four-point Y-axis and traverse X-axis control to support operator functionality further. In addition, uniform cooling on both sides, double polishing capabilities, reduced web stress, and consistent web orientation and thickness control promote high-quality, flat sheet with desired clarity.

In terms of extruders, we launched our new SHO and CHP series. Both extruders offer a more compact footprint with higher outputs to address profitability factors. With all components enclosed, these sleek designs extrude at rates up to 100 percent higher than traditional machines and provide faster purges between resins/colors. As a result, customers can benefit from reduced raw material loss, improved transition times, greater flexibility for upgrades, and better production outputs. The SHO is engineered for large-scale applications. The CHP offers coextrusion benefits for extrusion coating applications due to its compact footprint, lighter weight, and higher output.

And these are just a few examples. We are in a strong position to continue investing in machine tool upgrades that support manufacturing of key process components, as well as ongoing R&D investments, strong aftermarket services, and employee development. This is bolstered by the recent news that Davis-Standard was acquired by New York-based private equity firm Gamut Capital Management, L.P. We are excited to partner with Gamut during this next phase of our long history of providing highly engineered solutions to you, our industry-leading customers. Gamut resources will enable us to accelerate growth within various markets while ensuring you have the value-added resources and machinery technology needed to support your production and bottom-line objectives.

In closing, we are grateful for you, our customers, and the positive impact you make each day as you bring essential and influential products to market. Thank you for being on this journey with us. We wish you good health and all the best in the coming year!

Davis-Standard is pleased to introduce a new compact extruder engineered for extrusion coating applications – the CHP. The machine’s sleek design offers a smaller footprint and lighter weight to allow for easier addition to an existing carriage or platform structure. This provides processors with a space-saving replacement or coextrusion addition for increasing outputs and line speed.

“This design addresses profitability factors such as reduced raw material loss, improved outputs, and greater application development,” said Danis Roy, Davis-Standard Vice President – Sales Films & Flexible Packaging. “The CHP is built for exceptional performance with improved transition times and significantly higher processing rates than conventional extruders. We’re excited about the results we’ll see in the field.”

The CHP is available in sizes ranging from 2 inches (52mm) to 100mm. Processors benefit from efficient mixing that delivers low pressure and melt temperature variability and output rates up to 80 to100 percent higher than current extruder options. In addition, a reduced residence time of 3:1 with a faster purge between resins and colors supports quick changeovers minimizing raw material loss for bottom-line impact. Davis-Standard has a CHP extruder at its laboratory facility in Pawcatuck, Conn., for customers to run trials and validate processing opportunities prior to purchase.

For more information about the CHP or Davis-Standard’s extrusion coating capabilities, contact us today!

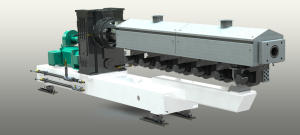

Davis-Standard is pleased to introduce the latest in the company’s groove feed innovation with the launch of its SHO extruder. Equipped to save space while offering outputs up to 20 percent higher than existing groove feed models, the SHO is engineered with an optimized feed section and high-performance, energy-efficient DSB® barrier screw. This is especially beneficial for high-viscosity HDPE applications such as pipe extrusion, where lower melt temperatures, reduced power consumption and improved energy efficiency are paramount.

Davis-Standard is pleased to introduce the latest in the company’s groove feed innovation with the launch of its SHO extruder. Equipped to save space while offering outputs up to 20 percent higher than existing groove feed models, the SHO is engineered with an optimized feed section and high-performance, energy-efficient DSB® barrier screw. This is especially beneficial for high-viscosity HDPE applications such as pipe extrusion, where lower melt temperatures, reduced power consumption and improved energy efficiency are paramount.

“Improving energy efficiency equates to tangible savings for your operation while reducing your carbon footprint,” said John Christiano, VP Technology. Groove feed extrusion technology contributes to improving your bottom line while providing uncompromising melt quality. “The SHO builds upon our existing groove feed technology with a more streamlined, compact footprint and even greater performance in terms of output and energy savings.”

The SHO features Davis-Standard’s next-generation gearcase to optimize valuable production space along with a streamlined hopper, low-profile power panel, rugged base, and all components fully enclosed. Advantages include improvements in output, output consistency, melt quality, reduced purging/changeover time, and energy efficiency. It is available in sizes ranging from 2 to 6 inches (50 to 150mm) with an L/D of 42:1.

For more information about the SHO or Davis-Standard’s groove feed extrusion capabilities, contact us today.

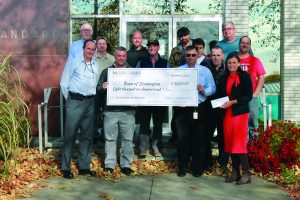

In recognition of Veteran’s Day, Davis-Standard is pleased to honor 41 veterans currently working at the company by donating to the Stonington Veterans Monument Project. Davis-Standard is making a contribution of $200 per veteran for a total of $8,200. In addition, each veteran at Davis-Standard received an appreciation gift for their service to our country.

“We are grateful for the contributions of each Davis-Standard employee who has served our great nation,” said Jim Murphy, Davis-Standard President and CEO. “Contributing to the Stonington Veterans Monument is a lasting way we can recognize those in our community who have given so much to protect our freedoms.”

The monument will include the names of all Stonington residents who have served in the armed forces since WWI, encompassing over 7,000 individuals. The granite monument will be located on the grounds of the Stonington police station and will feature etched drawings. Visitors will be able to read the names of all veterans, including future veterans, using a smartphone.

For more information about the monument, visit https://www.stonington-ct.gov/selectmens-office/pages/stonington-veterans-monument-project.

Davis-Standard is pleased to announce that Gianzo Mastrangelo has been promoted to Aftermarket Regional Manager for the Northeast U.S. and Canada. Mastrangelo will support existing installations and new opportunities within this territory, including developing and marketing aftermarket products and services for all Davis-Standard brands.

Mastrangelo brings 33 years of experience to this position, having held multiple leadership roles at Brampton Engineering as well as General Motors of Canada, CFM, Fenwick Automotive, and Embassy Flavours. This includes extensive knowledge of operations, manufacturing, process engineering, purchasing and sales. In addition, Mastrangelo holds a professional engineering license, has received Six Sigma Lean Manufacturing (Red X) training, and helped patent Brampton Engineering’s inflatable aqua ring component.

“Gianzo will be a tremendous asset to our North American aftermarket team,” said Joe Guigli, Davis-Standard Vice President of Aftermarket Sales. “He understands the needs of our customers in this territory, and the critical role we play in supporting equipment performance and better processing. He also brings an outstanding range of industry expertise that will strengthen our aftermarket initiatives.”

Mastrangelo has a Master of Business Administration, Bachelor of Science in mechanical engineering and Bachelor of Science in biology. He is a member of the Professional Engineers of Ontario in Ontario, Canada and holds a PEO license. For more information about Davis-Standard’s aftermarket capabilities, visit https://davis-standard.com/service-support/parts-and-upgrades/.

Read full article in the Pipe & Profile Magazine here.

Contact Us to inquire on products and services.