Improve Blow Molding Productivity

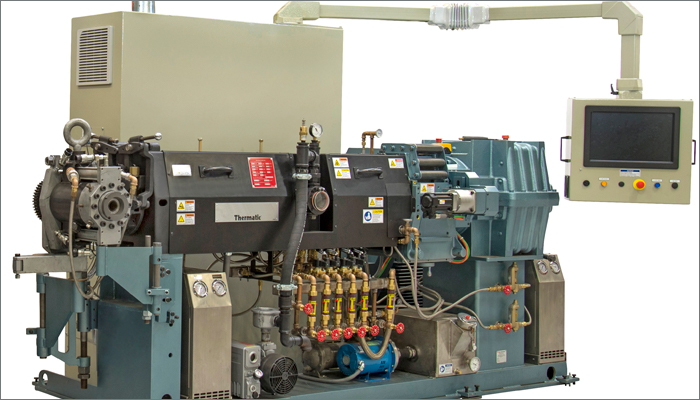

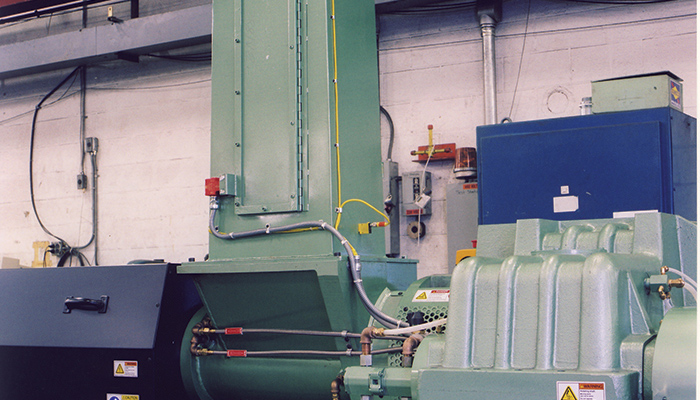

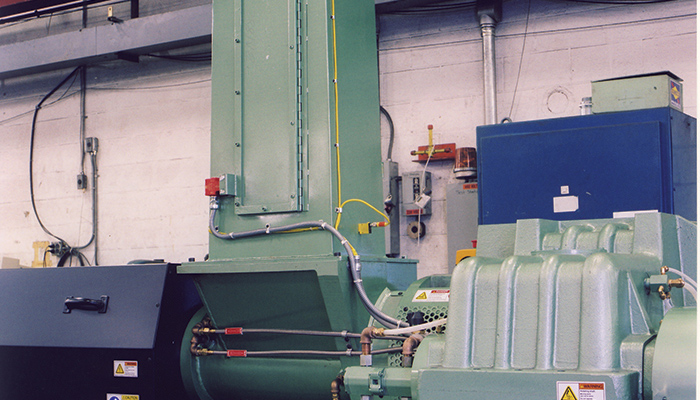

Davis-Standard offers custom-designed industrial blow molding machinery for a wide range of applications in the automotive and consumer product industries. Our flexible, custom-designed accumulator head blow molding systems feature closed-loop hydraulic and electronic controls and state-of-the-art screw design for processing both polyolefins and engineered thermoplastics.

Davis-Standard’s blow molding technology maximizes productivity with shot consistency, cycle-to-cycle precision, and excellent parison control. Our features, such as spiral head technology for faster color changes and efficient wall distribution, support cost-efficient operation.

Regardless of the blow molding application, Davis-Standard delivers quality molded parts with highly accurate wall thickness and density.

Toys, Household, Recreation and Industrial

Davis-Standard offers custom designed industrial blow molding machinery to meet your needs. Our flexible, custom designed accumulator head blow molding systems feature closed-loop hydraulic and electronic controls and state-of-the-art screw design for processing both polyolefins and engineered thermoplastics. Unmatched product innovation is driven by large part capabilities.

Features:

- Flexible, custom designed accumulator head blow molding systems

- Closed loop hydraulic and electronic controls

- State-of-the-art screw design for processing both polyolefins and engineered thermoplastics

- Extended machine life with retrofits and rebuilds including OEM quality controls upgrades, ANSI safety compliance, spiral core tube retrofits, head reconditioning, clamp rebuilds, replacement screws and barrels

- Spiral accumulator head technology to eliminate weld (re-knit) lines giving faster color changes and unmatched wall distribution

Retrofits and Rebuilds:

- Extends machine life

- OEM controls upgrades

- ANSI safety compliance

- Spiral core tube retrofits

- Head reconditioning

- Clamp rebuilds

- Replacement screws and barrels

READ MORE

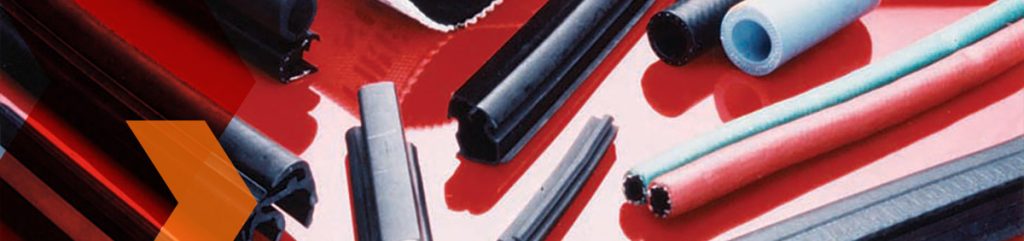

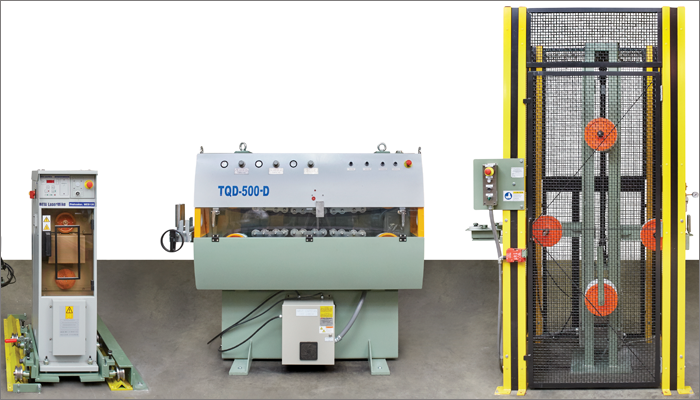

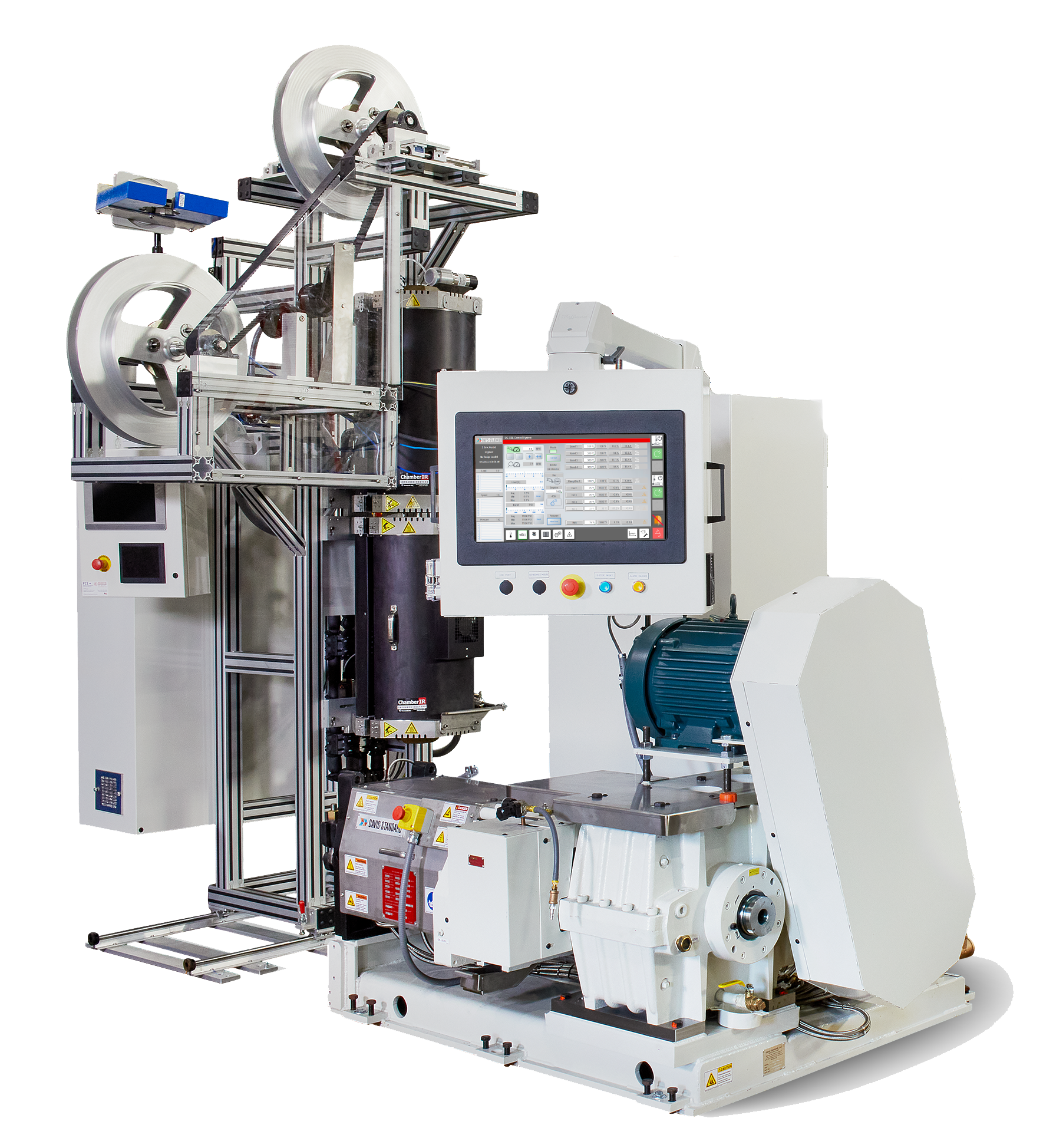

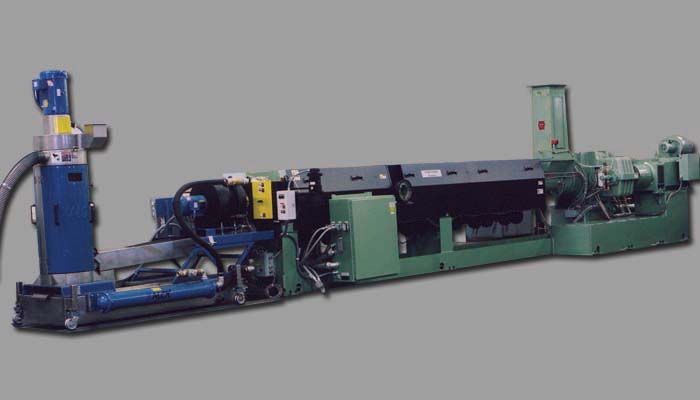

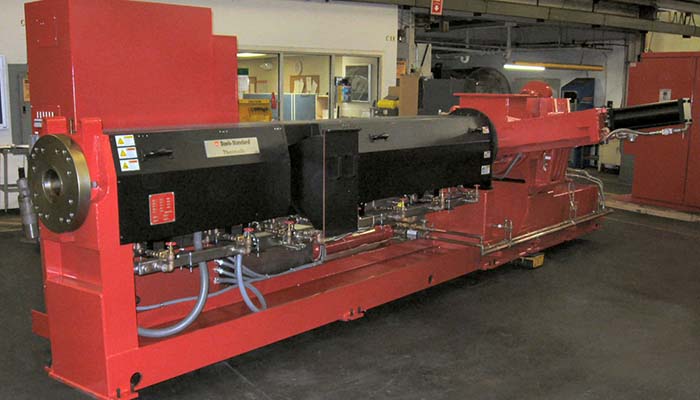

Leading Technology and Innovation for Your Elastomer Extrusion Requirements

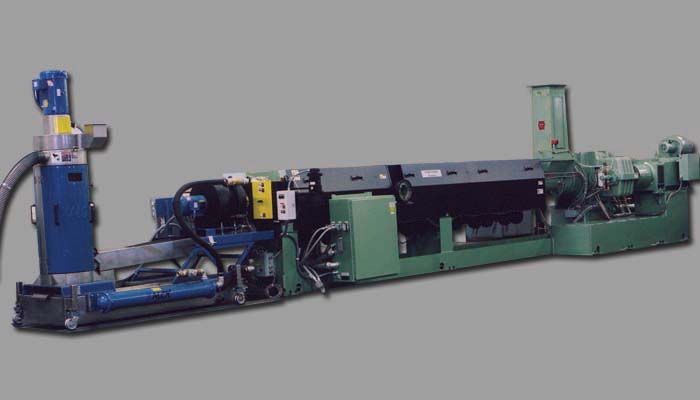

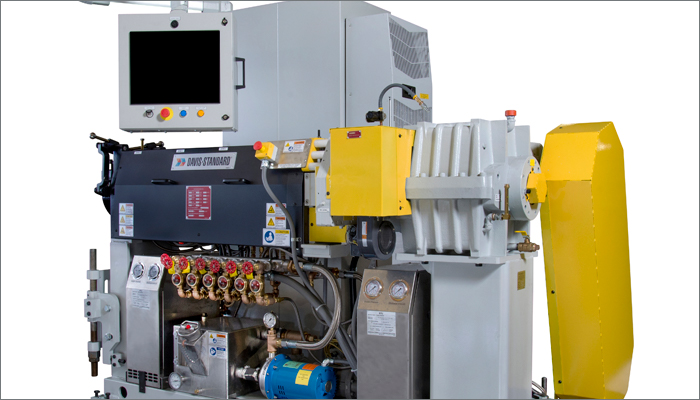

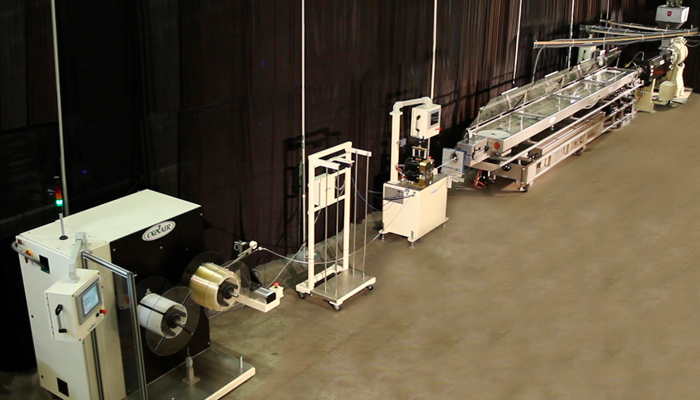

Davis-Standard’s elastomer extruders support global markets for tires, automotive hoses, adhesives and sealants, recreational equipment, construction and medical applications. We are industry leaders in complete rubber and silicone technology to support a range of applications including rubber hose, rubber and silicone gaskets, rubber barrier products, silicone tubing and weatherstrip.

With elastomer extruders in multipurpose, hot and cold feed, silicone, vacuum vented, pin barrel and smooth barrel designs, our extensive offering of elastomer systems provides a specific solution for nearly every elastomer application. Our engineers work with you to supply elastomer equipment that meets your precise product requirements, including technology for product curing and in-line processing.

Our advantage lies in decades of experience and knowledge of elastomer properties and processes for coextrusion, rubber straining and continuous vulcanization. That is why we also supply custom feedscrew designs, lab equipment, integrated process controls and complete systems—one-stop shopping for turnkey rubber extrusion.

Seals and Gaskets: Automotive

Davis-Standard has years of experience supplying elastomer extruders, components, and complete systems for automotive seals. Our elastomer customer base is Tier 1 with installations worldwide. We supply duplex, triplex and quadruplex profile heads for supported and unsupported rubber profiles. We are industry leaders in turnkey applications including carrier forming, curing, coating, flocking and cutting/sawing of profiles.

We understand the importance of each component and offer a wide range of Davis-Standard-built and Davis-Standard-specified elastomer equipment with experienced partners. This includes hot air and microwave curing ovens, pre-and post-formers for rigid carrier, flocking booths, cooling tanks, pullers, cutters, laser marking, printing and drilling.

An example of our advanced elastomer technology is our purpose-designed DSREV rubber extruder. Advantages include our patented pneumatic roll feed system to provide uniform, consistent feed rate; electric heat/water-cooled heating for quicker response time, lower maintenance and smaller machine footprint, rugged Davis-Standard gearboxes, and Davis-Standard's proven feedscrew designs to maximize output and minimize scorch.

Typical Specifications

Applications - Single and dual durometer unsupported seals, single and dual durometer supported seals, wire, stamped steel, breakable steel, and rigid steel supported seals

Line Speed Range - 6 to 30 mpm / 20 to 100 fpm

Size Range - 25 to 56 square cm / 1 to 9 square inches

Materials - EPDM Sponge, EPDM Dense, TPV/EPDM Compositions

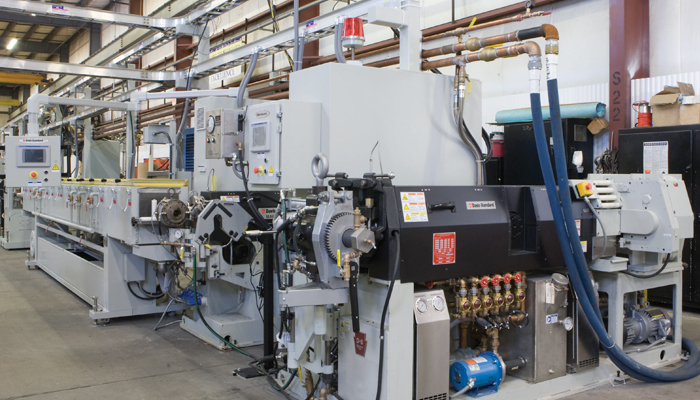

Hose: Industrial

With elastomer installations worldwide, Davis-Standard offers vast experience in supplying extruders, components, and complete systems for industrial rubber hose. We understand the importance of each component and offer a wide range of Davis-Standard-built and Davis-Standard-specified equipment with experienced partners. This includes laser and x-ray gauge control, pullers and cutters, textile reinforcement, cooling and anti-tack application tanks, adhesion-promoting systems, anti-tack dusting systems, laser-marking, printing and winding.

Examples of our preferred elastomer technology in this area include:

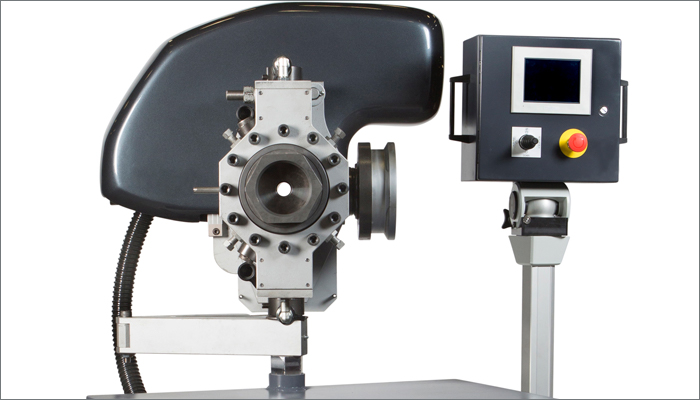

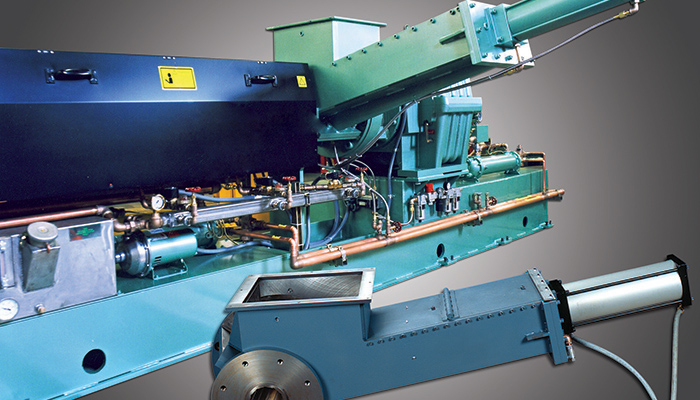

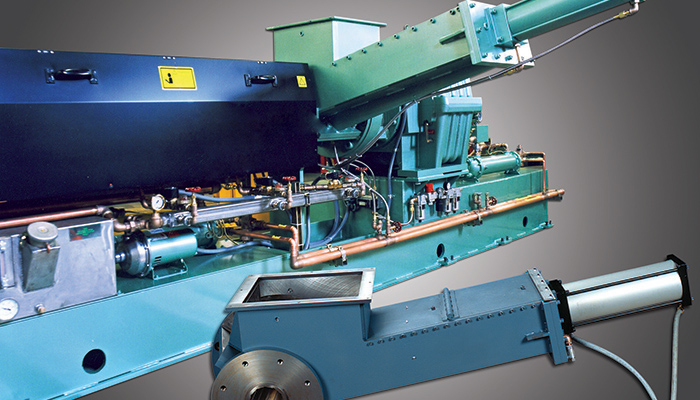

The DS Model 2000 crosshead – Features a tapered mandrel and highly engineered flow paths to ensure equal flow through all line speed ranges; propriety coating on wetted surfaces to increase wear resistance and provide easier clean-out; thrust bearing on pin adjustment to allow wall thickness adjustment without stopping the line; and hydraulic cylinders for quick and easy removal of the mandrel from the head body.

The DSREV rubber extruder – Features our patented pneumatic roll feed system to provide a uniform, consistent feed rate; electric heat/water-cooled heating for quicker response time, lower maintenance and smaller machine footprint; rugged Davis-Standard gearboxes; and proven feedscrew designs to maximize output and minimize scorch.

Typical Specifications

Applications - Composite spiral reinforced hose, composite knit reinforced hose, pole-built, 2-step wire reinforced hydraulic hose, multi-layer specialty fuel/gas hose

Line Speed Range - 1.5 to 100 mpm / 5 to 30 fpm

Size Range - 6 to 115mm / 250 to 4.5 inches

Materials - EPDM, NBR, SBR, FKM, ECO, THV, silicone

Hose: Automotive

Our elastomer systems and rubber extruders for automotive hose are widely used among Tier 1 customers worldwide. We understand the importance of each component and offer a wide range of Davis-Standard-built and Davis-Standard-specified equipment with experienced partners. This includes laser and x-ray gauge control, pullers, cutters, textile reinforcement, cooling and anti-tack application tanks, adhesion-promoting systems, laser marking and printing.

Examples of our preferred technology in this area include:

The DS Model 2000 crosshead – Features a tapered mandrel and highly engineered flow paths to ensure equal flow through all line speed ranges; propriety coating on wetted surfaces to increase wear resistance and provide easier clean-out; thrust bearing on pin adjustment to allow wall thickness adjustment without stopping the line; and hydraulic cylinders for quick and easy removal of the mandrel from the head body.

The DSREV rubber extruder – Features our patented pneumatic roll feed system to provide uniform, consistent feed rate; electric heat/water-cooled heating for quicker response time; lower maintenance and smaller machine footprint; rugged Davis-Standard gearboxes; and proven feedscrew designs to maximize output and minimize scorch.

Typical Specifications

Applications - Coolant hose, radiator hose, multi-layer THV/elastomer non-permeation fuel hose, A/C hose, turbo charger hose, brake hose

Line Speed Range - 1.5 to 30 mpm / 5 to 100 fpm

Size Range - 6 to 115 mm / .250 to 4.5 inches

Materials - EPDM, NBR, SBR, FKM, ECO , THV, silicone

Seals and Gaskets: Industrial and Architectural

We supply elastomer extruders, components, and complete elastomer systems for large and small continuous cure gasket lines for both rubber and silicone products. We understand the importance of each component and offer a wide range of Davis-Standard-built and Davis-Standard-specified equipment with experienced partners. This includes hot air and microwave curing ovens, salt bath curing tanks, standard and custom cooling tanks, pullers, cutters, laser marking, printing and winding.

An example of our advanced elastomer technology is our purpose-designed DSREV rubber extruder. Advantages include our patented pneumatic roll feed system to a provide uniform, consistent feed rate; electric heat/water-cooled heating for quicker response time; lower maintenance and smaller machine footprint; rugged Davis-Standard gearboxes; and Davis-Standard's proven feedscrew designs to maximize output and minimize scorch.

Typical Specifications

Applications - Coolant hose, radiator hose, multi-layer THV/Elastomer non-permeation fuel hose, A/C hose, turbocharger hose, brake hose

Line Speed Range - 1.5 to 30 mpm / 5 to 100 fpm

Size Range - 6 to 115mm / .250 to 4.5 inches

Materials - EPDM, NBR, SBR, FKM, ECO , THV, silicone

Silicone Tubing

Davis-Standard has extensive process and extrusion expertise in the area of medical and industrial silicone tubing worldwide. We understand there is a difference between extruding an industrial fluid transfer tube and extruding an infantile catheter. Our engineers work with you to supply the correct customized equipment to meet your precise product requirements including horizontal or vertical extrusion, short-wave or medium-wave cure systems, custom designed dies and downstream equipment, or precision cutting and winding.

An example of our preferred extrusion technology in this area includes our DSR silicone extruder. Advantages include our patented pneumatic roll feed system to provide uniform, consistent feed rate, chrome plating and stainless steel contact surfaces for medical environments, available hinge-roll feed roll section for easy cleanout and compound changes, rugged Davis-Standard gearboxes, and proven feedscrew designs to maximize output and stability.

Typical Specifications

Applications - Medical silicone catheters, wound drainage tubing, specialized tubing, Medical silicone tubing (multi-lumen), radio-opaque stripe, farm/dairy silicone tubing and multi-layer hose, industrial silicone tubing, specialty silicone gaskets

Line Speed Range - 1.5 to 23 mpm / 5 to 75 fpm

Size Range - 2.5 to 50mm / 100 to 2 inches

Materials - Medical and industrial grade silicone compounds, heavily filled, conductive silicone compounds

Model 3000 Crosshead

- Tapered mandrel designed for stable concentricity

- Engineered flow path through head maintains equal flow across speed ranges

- Rigid die holder maintains concentricity adjustment when dies are changed

- Die adjusting screws are in removable inserts to protect body from thread damage

- Thrust bearing allows easy pin adjustment to change wall thickness

- Larger surface area in water jacket for better heat transfer

- Manufactured from AISI 4140 heat treated steel with all inside surfaces coated with Armalloy for improved wear resistance, material flow, and clean-out

- Hydraulic mandrel removal with air operated hydraulic pump and control valve

- Mandrel swings/slides out

- Standard models available to cover 2” (50mm), 3” (76mm), 4.5” (102mm) and 5.5” (140mm) diameter braid

- 2” and 3” models include pintle mount on a Davis-Standard hinge and scissor-arm support for mandrel removal; 4.5” and 5.5” model includes support cart with mandrel removal facilitated by linear rails on the cart

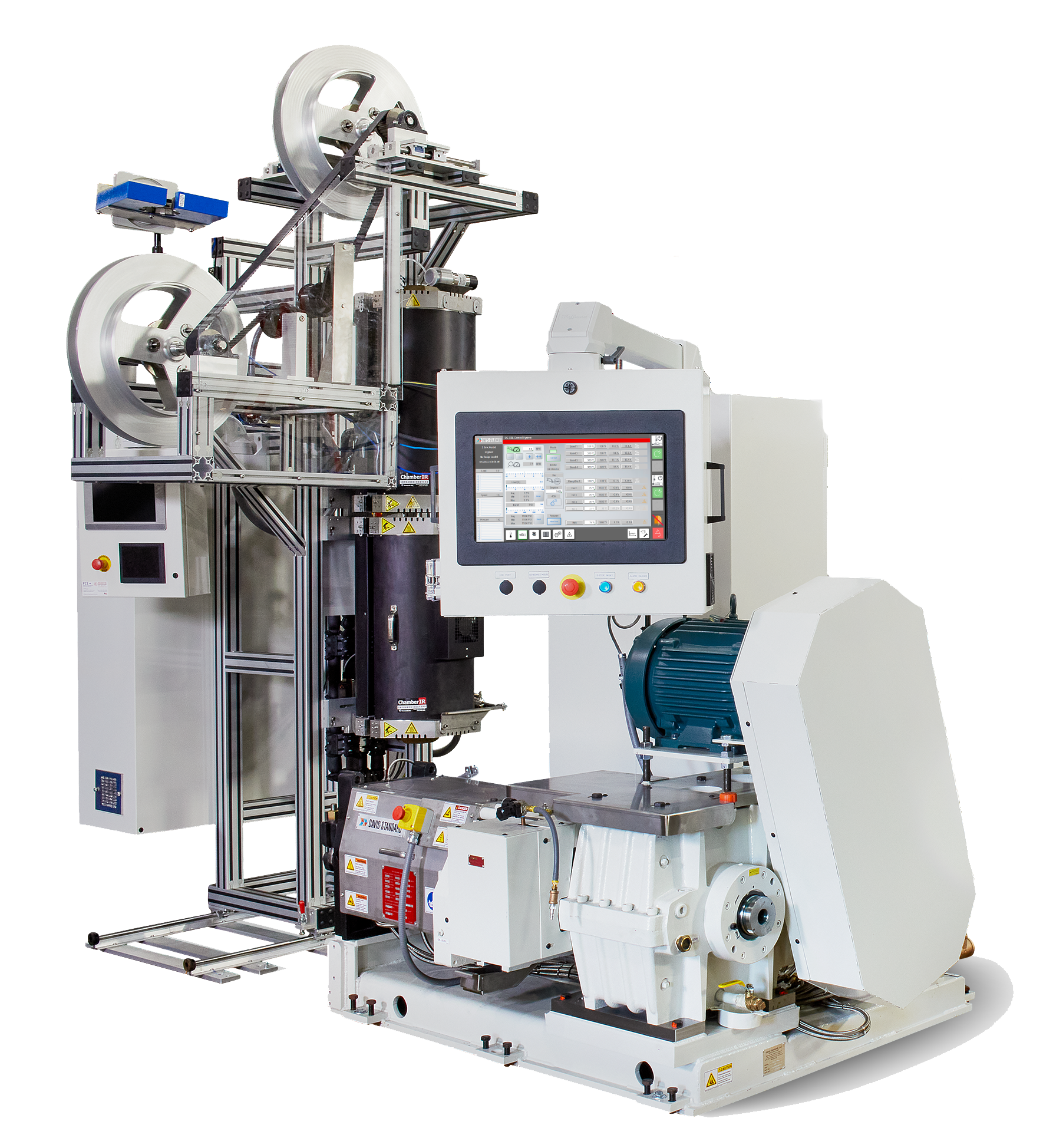

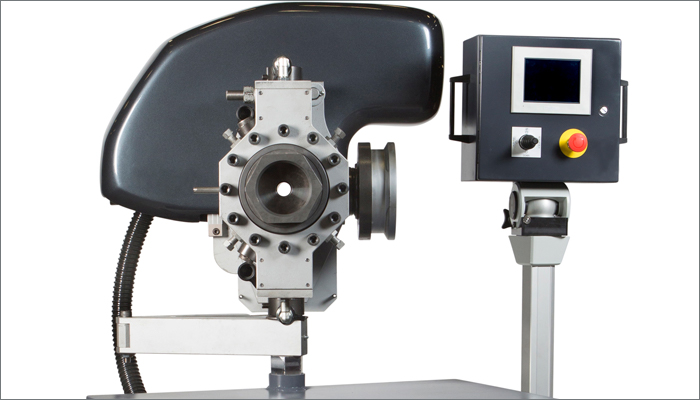

Model 3000A Crosshead

The Model 3000A incorporates an automatic, servo-driven concentricity adjustment system. This new, proprietary system allows for adjustment of the core tube/tip assembly with simple, accurate joystick control. This enables the operator to easily minimize eccentricity, maximize concentricity, and reduce downtime during product changeovers. In addition, the servo drives enable monitoring and adjustments throughout the run to account for lot-to-lot variations, day/night variations, and gum space corrections. The compact design does not require a hydraulic pump system or hoses.

- Tapered mandrel designed for stable concentricity

- Engineered flow path through head maintains equal flow across speed ranges

- Rigid die holder maintains concentricity adjustment when dies are changed

- Die-adjusting screws are in removable inserts to protect body from thread damage

- Thrust bearing allows easy pin adjustment to change wall thickness

- Larger surface area in water jacket for better heat transfer

- Manufactured from AISI 4140 heat treated steel with all inside surfaces coated with Armalloy for improved wear resistance, material flow, and clean-out

- Hydraulic mandrel removal with air-operated hydraulic pump and control valve

- Mandrel swings/slides out and is supported for safe and easy cleaning

- Standard models available to cover 2” (50mm), 3” (76mm), 4.5” (102mm) and 5.5” (140mm) diameter braid

- 2” and 3” models include pintle mount on a Davis-Standard hinge and scissor-arm support for mandrel removal

- 4.5” and 5.5” models include support cart with mandrel removal facilitated by linear rails on the cart

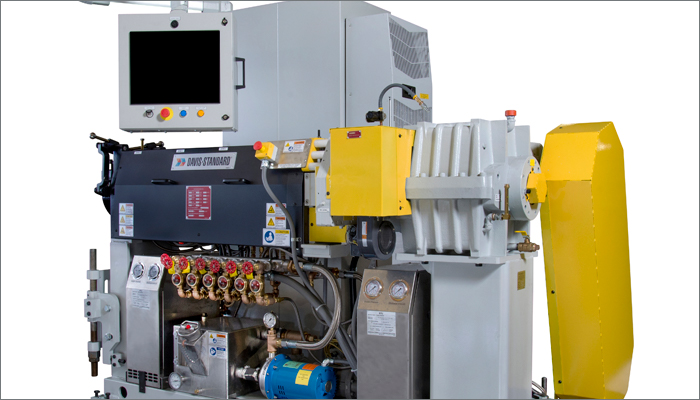

Model 4000AG Crosshead

The Model 4000AG incorporates an automatic, servo-driven concentricity and wall thickness adjustment system. This new, proprietary system allows for adjustment of the core tube/tip assembly with simple, accurate joystick control. This enables the operator to easily minimize eccentricity, maximize concentricity, and reduce downtime during product changeovers.

In addition, the servo drives enable monitoring and adjustments throughout the run to account for lot-to-lot variations, day/night variations, and wall thickness corrections.

The compact design does not require a hydraulic pump system or hoses. This system also includes stepper-driven wall thickness adjustment, eliminating the requirement of hand tools and intrusive thickness measuring devices.

Additional features such as a tapered mandrel and highly-engineered flow paths ensure consistent flow through all speed ranges. Heat transfer efficiency has been optimized by using computer analyzed software for design of water-cooling jacket.

Models are available to accommodate 2-inch (50mm), 3-inch (76mm), 4.5-inch (102mm) and 5.5-inch (140mm) diameter braids.

- Tapered mandrel designed for stable concentricity

- Engineered flow path through head maintains equal flow across speed ranges

- Rigid fixed die holder maintains concentricity adjustment when dies are changed

- Slew Ring allows easy pin adjustment to change wall thickness via spring center return toggle switch

- Enhanced water jacket design for better heat transfer

- Manufactured from AISI 4140 heat treated steel with all inside surfaces coated with Armalloy for improved wear resistance, material flow, and clean-out

- Hydraulic mandrel removal with air-operated hydraulic pump and control valve

- Mandrel swings/slides out and is supported for safe and easy cleaning

- Standard models available to cover 2-inch (50mm), 3-inch (76mm), 4.5-inch (102mm) and 5.5-inch (140mm) diameter braid

- 2 and 3-inch models include pintle mount on a Davis-Standard hinge and scissor-arm support for mandrel removal

- 4.5-inch and 5.5-inch models include support cart with mandrel removal facilitated by linear rails on the cart

- Most existing Model 2000 and 3000 heads can be retrofitted to take advantage of the Model 4000AG automated design features (X-Ray gauge and controller is required to provide a signal back to the Davis-Standard PLC Controller)

No post found

READ MORE

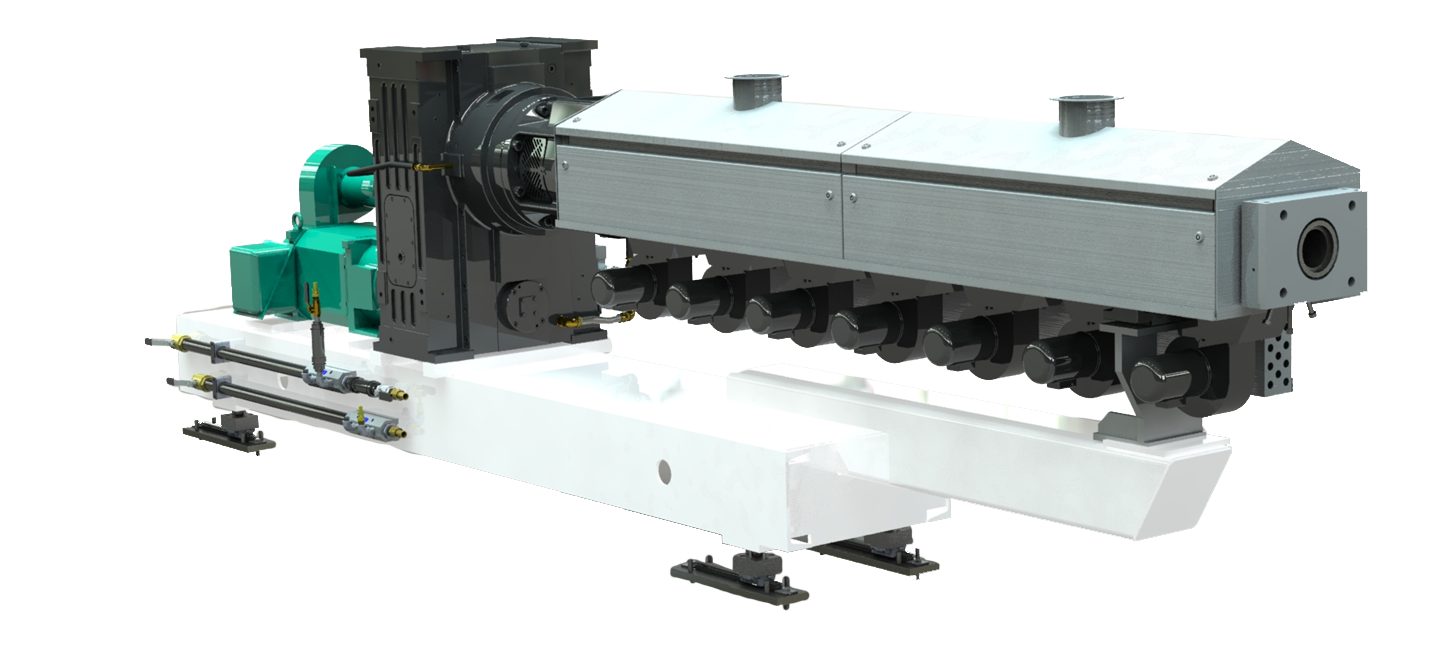

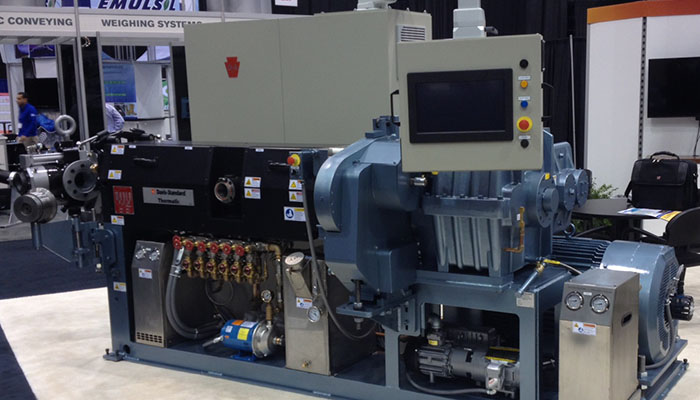

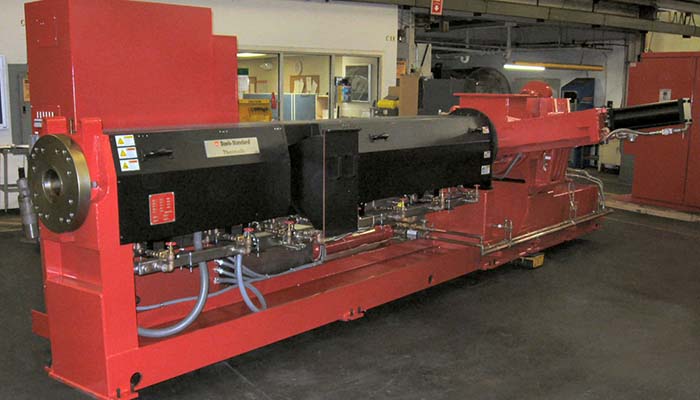

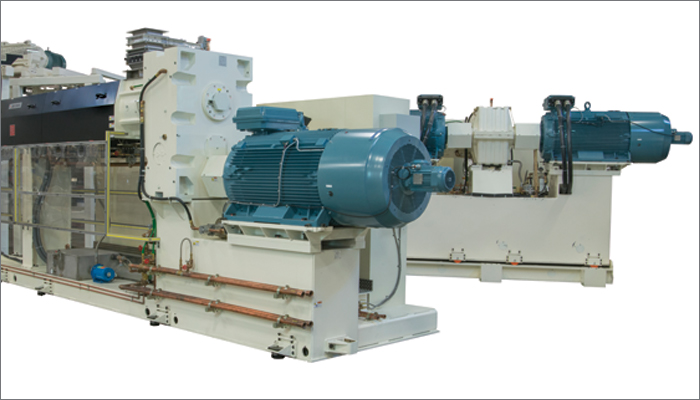

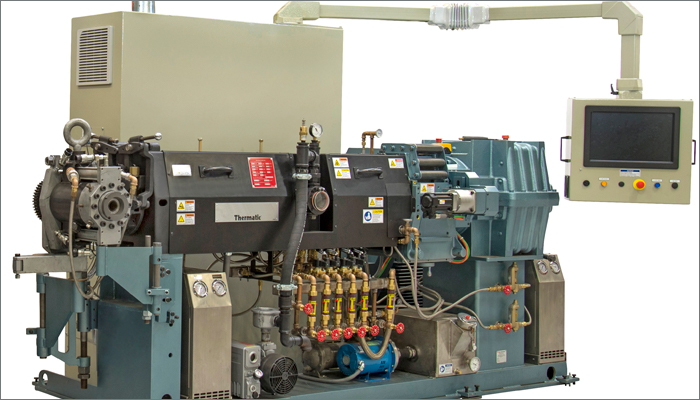

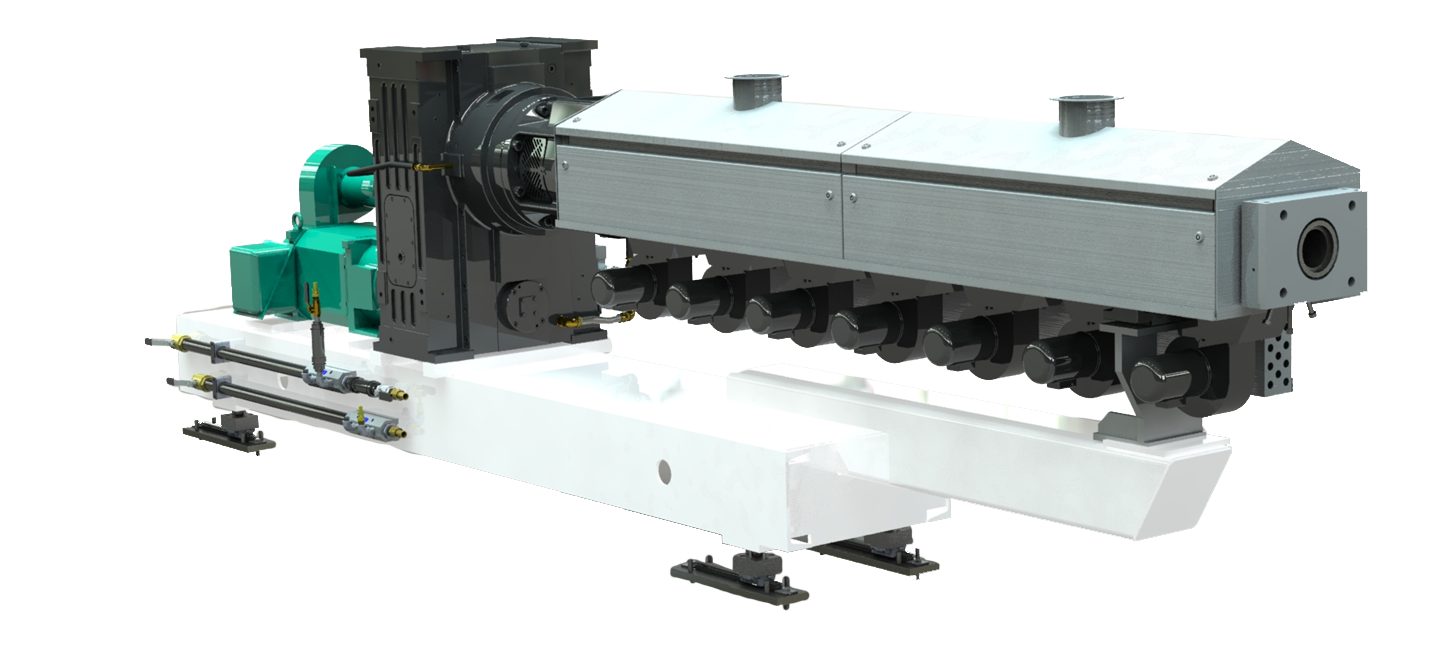

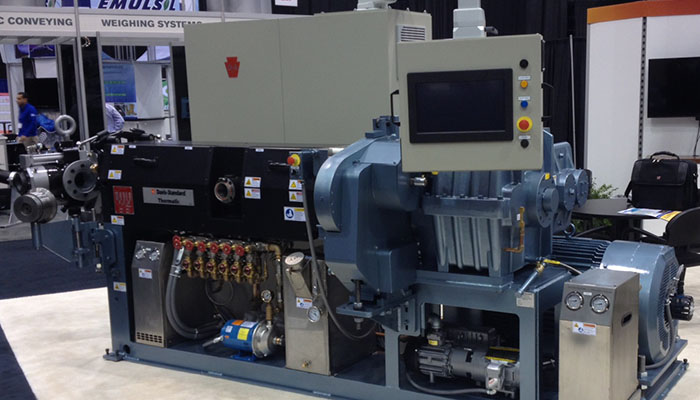

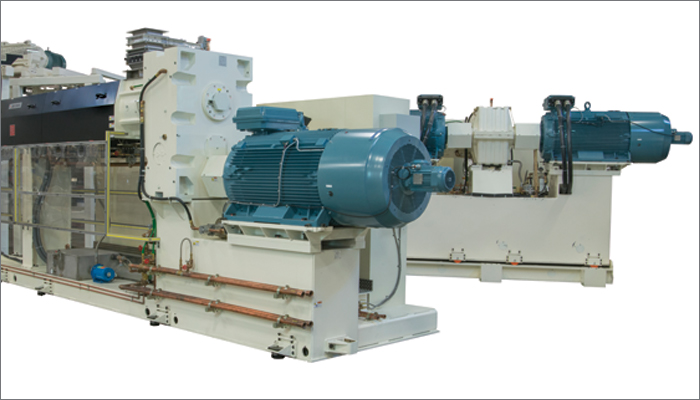

The Industry’s Premier Extruders

What separates a Davis-Standard extruder from the competition? Our customers will tell you it’s the unparalleled performance and durability that makes the difference. Our extruders are so reliable that some are still operating after 50 years of continuous service. This track record combined with high output rates and a rapid return on investment make Davis-Standard extruders the workhorses of the industry.

From single and twin screw extruders to specialty, reclaim, medical and elastomer extruders, the depth and availability of our extruder offering is what makes Davis-Standard the global extrusion leader. We are also recognized for our coextrusion technology, supporting both vertical and horizontal coextrusion configurations.

Regardless of application or location in the world, we have the extruder to suit your requirements and budget.

Elastomer Extruders

Cold Feed (DSR) Rubber Extruders

- Available in 2 1/2 inches (65mm) to 6 inches (150mm) with L/D ratios of 10.5:1, 12:1, 15:1, 17:1 and 20:1

- Equipped with unique pneumatic roller feeder to compensate for feed strip variations

- Improved output stability

- Multi-zone temperature control via double cast aluminum heater cooler

Gear Extruders

- Available in 70, 120 and 150mm sizes and with 200, 300 and 370mm screen diameters

- Two-roll feeder for single and multiple strip feeding

- Hydraulic head clamp

- Three temperature control zones

- Touchscreen PLC control

- Dual head capability

- Dancer trim control and feed strip detectors

Cold Feed Rubber Silicone Extruders

- Available in 1 1/2 inches (40mm) to 8 inches (200mm) with L/D ratios of 10.5:1 and 7:1

- Available as a silicone strainer, with a vertical crosshead, and in Lo-Boy configurations

- Unique pneumatic roller feeder to compensate for feed strip variations

- Optional stainless steel hopper with sight glass for pellet stock capability

Multipurpose Cold Feed (DSRE) Rubber Extruders

- Available 1 1/2-inch (40mm) to 8 inches (200mm) with L/D ratios of 20:1

- Equipped with unique pneumatic roller feeder to compensate for feed strip variations

- Multi-zone temperature control via double cast aluminum heater coolers

Single Screw Extruders

Thermatic® Extruders

- Diameters: 1-1/2-inch to 12-inch (40mm-305mm)

- Top of the line for all polymer requirements

- Air or water cooled as standard

- Integral or free-standing control panel

- Double reduction gearbox with hardened gears available

- Pressure lubrication on gearbox

Super Blue® Extruders and EuroBlue® Extruders

- Diameters: 2-inch (50mm), 2-1/2-inch (65mm), 75mm, 3-1/2-inch (90mm)

- Standard cost-effective design

- Double reduction gearbox

- Air cooled

- Control panel mounted on base

- Delivery as quick as two weeks from the order date

Groove Feed Extruders

- Diameters: 2-inch to 6-inch (50mm-150mm)

- 36:1 effective L/D ratio

- High output for polyolefin materials

- Double reduction gearbox

- Pressure lubrication on gearbox

HPE-Horizontal Extruders

- Diameters:3/4-inch (20mm), 1-inch (25mm), 1-1/4-inch (32mm), 1-1/2-inch (38mm) & 1-3/4-inch (45mm)

- Caster mounted for portability

- Double reduction gearbox

- Compact design

- Integral control panel mounted on base

HPE-Vertical Extruders

- Diameters: 3/4-inch (20mm), 1-inch (25mm), 1-1/4-inch (32mm), 1-1/2-inch (38mm) & 1-3/4-inch (45mm)

- Utilized in coextrusion applications

- Motorized and manual position available

- Vertical design for space consideration

- Control panel mounted on base

MEDD Extruders

- Diameters: 3/4-inch (20mm), 1-inch (25mm)

- (40mm)

- Direct drive motor

- Replaceable feed section liner

- Compact design for medical applications

- Interchangeable barrel liners

Thermatic® High-Speed Extruder

- Maximum Drive Power: 600 HP

- Maximum Speed: 1200 RPM

Twin Screw Extruders

Gemini® Conical (GC) Twin Screw Extruders

- Available GC-40: 1.6/3.4-inch (40/86mm), GC-61: 2.4/5.1-inch (61/130mm), GC-65: 2.5/5.1-inch (65/165mm)

- Low rpm screws with internal sealed water-cooling systems

- Rugged, high-performance gearbox

- Flood feed capacity

- High-efficiency Thermafin air-cooled barrel heaters and sealed

- Water-tempered screws

Gemini® Parallel (GP) Twin Screw Extruders

- Models: GP-94, GP-114, GP-140

- Low RPM design

- High torque gearbox

- Equipped with a control cabinet and drive motor mounted on a common base

- Preheater available on GP-114 and GP-140 models

Compounding & Reclaim Extruders

Ram Stuffer Extruders

- Diameters: 3 1/2-inch (90mm), 4 1/2-inch (115mm), 6-inch (150mm), 8-inch (200mm)

- Designed for reclaiming low bulk density feedstocks

- Pneumatic ram to stuff material into the screw

- Extra large feed throat to maximize feeding in low bulk density material

Scrapper® Dual Diameter Extruders

- Extra large feed throat and feed assist components for added efficiency

- Widely used ram stuffer and crammer extruders available

- Models: 350/600 (Process/Feed), 450/800 (Process/Feed), 650/1000 (Process/Feed)

- Ideal for processing scrap in web form directly from rolls, low or high bulk density material

- Feed assist component eliminates cost of shredding, grinding, and densification

Hot Melt Extruders

- A throat opening that is 12 to 14 times the size of standard throat openings

- Capable of batch, continuous, or rope feeds

- L/D that is designed for specific applications

- Vented barrel available to assist with issues related to volatiles

Scrap Reclaim Extruder

- Diameters: 3 1/2-inch (90mm), 4 1/2-inch (115mm), 6-inch (150mm)

- Gear reducer, feed section, barrel and drive motor are mounted to a rugged base

- Aggressive feedscrew designs for increased production rates

- Barrels are bimetallic lined for long wear

No post found

READ MORE

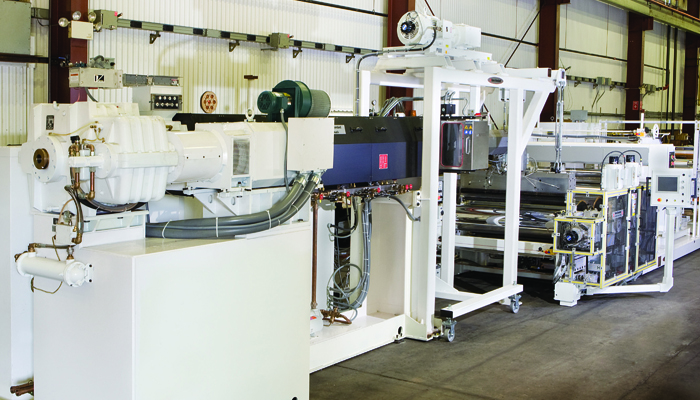

Industry Leading Foam Extrusion

We are an industry leader in foam extrusion. Whether you’re trying to achieve a specific product density or insulation characteristic, Davis-Standard foam extrusion capabilities make it possible. Our turnkey foam solutions are backed by proven technology and excellent results, enabling us to excel in food packaging, construction and consumer products industries.

Davis-Standard’s single and twin-screw tandem foam lines, and in-line foam technology are recognized industry-wide thanks to high output processing of PE, PS and PP foam sheet. Not only do we offer the highest industry foam outputs per tandem line size, our systems allow for direct processing of foam flake, removing the need for pelletizing.

Insulation Board (XPS)

Our turnkey solutions for sheet used in board for insulation and construction applications are backed by proven technology and excellent results. Advantages of our experience and capabilities include:

- Highest industry outputs per tandem line size

- Systems that allow direct processing of foam flake, removing the need for pelletizing

- Proprietary flat die designs for high-performance requirements

- High-performance low energy secondary screw designs

We supply a wide range of Davis-Standard-built and Davis-Standard-specified equipment with experienced partners. Our application engineering is second to none, and we work side-by-side with customers to deliver solutions that meet production demands. Proven feedscrew designs and control system options further support system performance. This includes connectivity solutions for remote data access via laptop and Web browsing as well as multi-level security to protect set-up functions and accessibility.

Typical Specifications

Applications - Insulation board

Line Speed Range - Up to 50 mpm / Up to 150 fpm

Thickness Range - 20 to 100 mm / 0.787 to 4 inches

Materials - PS

Protective Packaging (PE Foam)

Davis-Standard has extensive experience in supplying complete systems for foam sheet used in protective packaging applications. Process advantages include:

- Highest industry outputs per size

- High-performance primary for best distribution and high gas percentages

- Breaker plate and spider-less die designs depending on requirements

- Die gap toggle feature for passing melt contaminates

- Precise concentricity adjustment with fine die gap adjustment

- Low energy secondary screw designs

We supply a wide range of Davis-Standard-built and Davis-Standard-specified equipment with experienced partners. Our application engineering is second to none, and we work side-by-side with customers to deliver solutions that meet production demands. Proven feedscrew designs and control system options further support system performance.

Typical Specifications

Applications - Protective packaging

Line Speed Range - Up to 50 mpm / Up to 150 fpm

Thickness Range - 20 to 100 mm / 0.787 to 4 inches

Materials - PE

Disposable and Food Service Packaging (PS Foam)

Our global experience in supplying sheet lines used in thermoformed packaging has made us a sheet extrusion leader. We understand the importance of each component and offer a range of Davis-Standard built and sourced equipment from trusted partners. We work with each customer to identify and address production demands to positively impact the bottom line.

Advantages of our capabilities in this area include in-line and off-line thermoforming sheet designs; high-speed extrusion systems, non-dried and dried APET solutions; on-line low bulk density scrap re-processing capabilities, single or multi-lane extrusion for optimal cooling, special FFS quality sheet line designs, and unique nipping and non-nipping auxiliary cooling carts.

Typical Specifications

Applications - Thermoformed packaging, form fill seal (FFS) packaging

Line Speed Range - .5 to 60 mpm / 5 to 200 fpm

Thickness Range - 0.25 to 2.5mm / 0.010 to 0.100 inches

Materials - HIPS, PP and PET

No post found

READ MORE

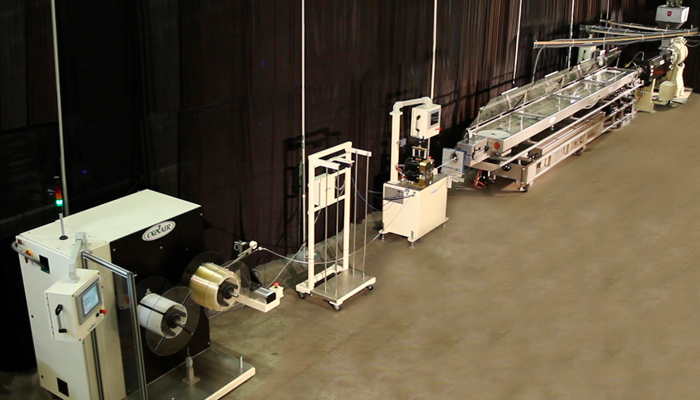

Global Leadership in Pipe, Profile and Tubing

Davis-Standard has been a global leader in pipe, profile, and tubing extrusion for over 50 years. Our extrusion systems and extruders support multi-layer pipe extrusion, automotive tubing and seals, medical tubing, agriculture pipe, telecommunications pipe, and building profiles among others.

Continuous improvement in extruders, controls, feedscrew technology and process support has positioned Davis-Standard at the forefront of pipe, profile and tubing innovation. From our six-layer automotive fuel delivery tubing systems to advantages in PVC profile extrusion, our capabilities range is as broad as the application areas we support.

Whether your extrusion application requires tight tolerance tubing, high output gas and water pipe lines, or custom profile systems, look to Davis-Standard for your global pipe, profile and tubing needs.

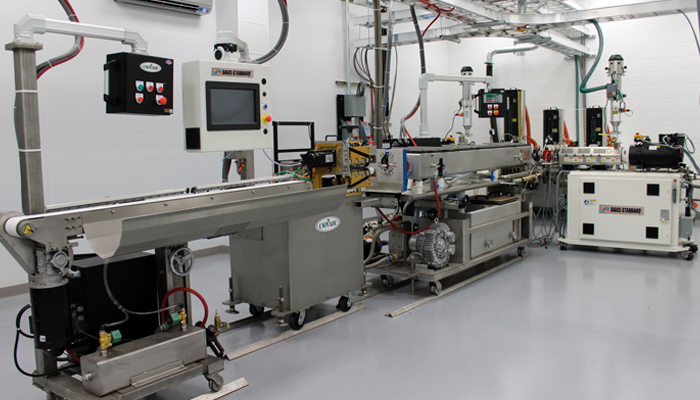

Custom & Stock Extruders

Davis-Standard’s pipe, profile and tubing extruder range and extrusion technology is as broad as the application areas we support. Every extruder is available with a range of control systems and feedscrews to achieve results-driven performance.

- Super Blue® and Euro Blue® extruders are built with the same high-quality components as our engineered machines. Extruder stock orders are built for quick delivery with two to four-week shipments common for 3 1/2-inch, 2 1/2-inch, and 2-inch machines. Other sizes are available as well. Contact us for additional information.

- HPE single screw co-extruders, (3/4 to 1 3/4 inches) incorporate a direct motor drive system eliminating the need for drive belts.

- The MEDD line of medical extruders is designed with water-cooled permanent magnet synchronous motors, eliminating the need for oils and grease inside a cleanroom. The extruder base is also the control panel providing space-saving layouts and all stainless steel design for cleanroom applications. Sizes include: 3/4 –1-inch 24:1 L/D, 1 –1.25 inches 24:1 L/D, and 1.25 – 1.5 inches

- The high output, low melt temperature Thermatic® groove feed single screw extruder is engineered for the demanding water and gas pipe industry. A 3 1/2-inch 38:1 groove feed extruder in our Connecticut lab is available for output and mixing testing on your materials.

Polyethylene Pipe & Tubing

Davis-Standard is a global leader in the design and manufacture of HDPE pipe and tubing extrusion systems and extruders. Our technology covers all major pipe and tubing markets and includes advanced control system technology. Examples of major markets we support worldwide include telecommunications, construction and agriculture.

- Extrusion of telecommunication HDPE duct for fiber optics including multilayer HDPE and silicone micro ducts, and packaging of several micro ducts into a common HDPE cover

- Extrusion of PEX tubing for home heating and cooling including single layer PEX and PEX with an EVOH outer layer

- Extrusion of agriculture corrugated drainage pipe co-designed with major corrugator suppliers, including high-pressure melt pumps, continuous screen changers, and gravimetric feeding systems

Typical Specifications

Applications - Telecommunications duct, water pipe, gas pipe, dip tube, PEX heating and cooling tubing, corrugated drain tile

Line Speed Range - 1.5 to 304 mpm / 5 to 1000 fpm

Size Range - 2.5 to 1,525mm / 0.100 to 60 inches

Materials - HDPE, PE-100, PE-80, LLDPE, LDPE

Automotive Tubing & Seals

Davis-Standard is a global supplier of multilayer automotive tubing extruders and extrusion systems for fuel delivery system applications. Our extrusion technology is designed to process three, four, five and six-layer PA and barrier layer tubing on the same extrusion line at line speeds up to 130 fpm for 8mm tubes. We also supply complete TPE seal systems. Multi-layer extrusion systems incorporate material handling and drying, four extruder co-extrusion feed blocks, and downstream equipment consisting of primary cooling and sizing tanks, haul-offs, servo fly-knife cutters and take-away tables.

Typical Specifications

Applications - Multilayer fuel delivery tubing, automotive seals

Line Speed Range - 1.5 to 40 mpm / 5 to 130 fpm

Size Range - 6 to 12mm tubing, 645 –1935 sqmm profiles / 0.236 to 0.472 inches tubing, 1 to 3 square inch

Materials - PEBAX, PA, HDPE, FPVC, TPE, FEP, TPU, THV

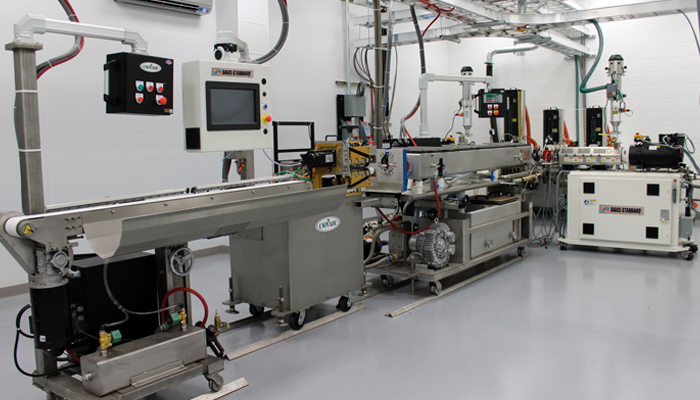

Medical Tubing

Davis-Standard understands the extrusion needs of the global medical tubing market – tight tolerances, high speeds, clean room specific designed equipment, and process support. We work with your engineering team to design the right extrusion system for your tubing needs, including extruders, controls, tooling, and screw designs. Our lab lines in Pawcatuck, Connecticut support new medical tubing application development such as microbore catheter tubing, multi-lumen tubing, and bump tubing. Davis-Standard’s product line can offer our customers complete extrusion solutions for numerous products, materials, and line speeds.

Typical Specifications

Applications - Multi-lumen tubing, Fluoropolymer tubing, High-speed PVC, bump/taper tubing, alternate polymer tubing, coextrusion, respiratory tubing, silicone tubing, and more

Line Speed Range - up to 800+ fpm (243+ mpm) base on application

Size Range - 0.010-inch (.254mm) and up depending on the application

Materials - PEBAX, PA, HDPE, FPVC, TPE, FEP, TPU, and more

No post found

READ MORE

Flexible and Customized Extrusion Control Solutions for Every Process

- DS-eTPC touch-screen control

- DS-Tablet hand-held operator interface

The brain of the extruder drives your operation and smarter process controls make a huge impact on the bottom line. That is why every system in Davis-Standard’s full line of process controls is operator-friendly, efficient and reliable. From discrete to full supervisory control, our control systems are engineered in-house to ensure quality and value.

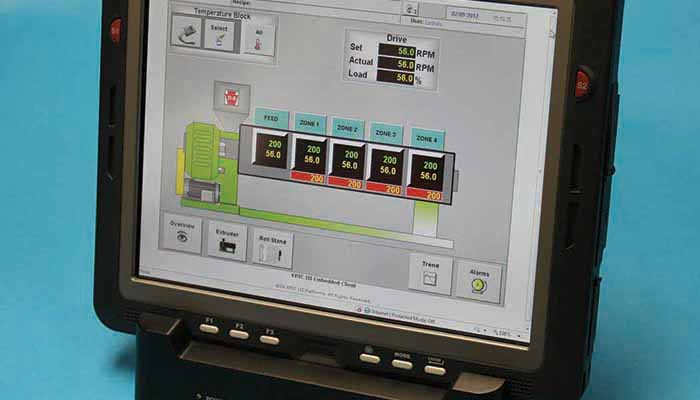

The signature EPIC III® and Integrator controls, the portable DS-Tablet and affordable DS-eVUE are just a few of our technologies that take the guesswork out of your extrusion operation. Davis-Standard’s proven systems do the thinking for you about systems integration, temperature control and process controls.

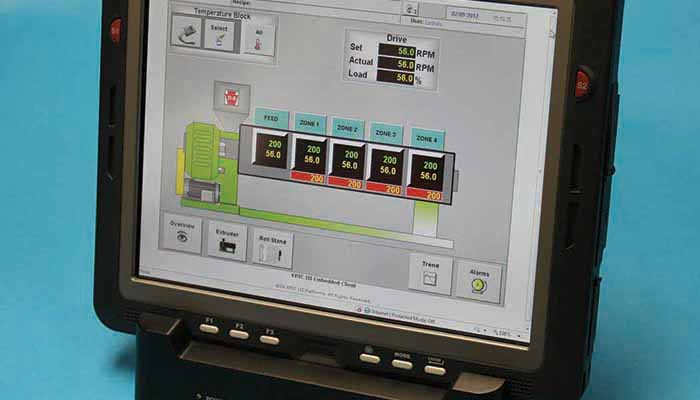

EPIC III®

Davis-Standard's EPIC III® is an advanced Windows®-based touch screen extrusion process control system offering complete plant management and process control capabilities. Advantages include:

- Adaptable and expandable touch screen displays

- Supervisory features: event logging, customized reports, SQC, historical trending, maintenance/troubleshooting, pressure set-up and more

- Partial and complete line overview, detailed extruder data, recipe creation/storage, etc.

- iFIX™ SCADA software for Windows®

- ControlLogix™ PLC platform (optional Siemens S-7)

- Connectivity solutions for remote data access via laptop and Web browsing

- Object linking and embedding for process control

- A multiple-level security system to protect set-up functions and accessibility

- Network capability for remote monitoring of multiple systems

- Available DVD writer and removable hard drive for secure system data back-ups

EPIC IV®

Davis-Standard’s EPIC IV® integrates a high performance HMI experience with supervisory control for complex systems. With Windows®-based plant management and extensive process control capabilities, the EPIC IV can be customized for any extrusion or converting application. Supervisory features include alarm and event logging, customized real-time reports, SQC, historical trending, data collection, maintenance/troubleshooting help files, calibration, tuning, and more.

- iFIX SCADA software for Windows®

- Premium connectivity solutions enable the EPIC to communicate with a wide variety of third party equipment.

- ControlLogix PLC platform standard

- Best-in-class historian software solution that collects, stores, and retrieves data efficiently and securely

- ReACT - Remote access for service and support - requires an Internet connection

- Multi-level security system to protect set-up functions and accessibility

- OPC UA server available for MES/ERP connectivity.

- Multi-Language support for global availability

- Adaptable and expandable touch-screen displays

- Machine KPI data clearly displayed on line overview and control screens that are customized to match the specific application

DS-eVUE

The DS-eVUE combines many features of the EPIC III® with the low-cost requirements of previous HMI applications. Features include:

- 15-inch widescreen

- Graphics overview

- Reports

- Trending

- Event log

- Data collection

- WEB interface (2 concurrent users)

- Email notifications

- FDA-21 Part 11 ready

- Electronic signatures

DS-eTPC

The DS-eTPC (touch panel control) offers comprehensive integrated touch-screen control with attractive pricing. Advantages include:

- Coordinated line drive control (standard feature)

- Operator friendly design

- Cold start inhibit

- High and high-high alarms for each pressure point

- Recipe creation and storage

- Provision for system networking to a supervisory computer via Ethernet LAN

- Pre-configured and engineered levels with added temperature and line control options

- Optional closed loop pressure control for melt pump operation, additional line drive and heat zones

- Optional line drive

DS-XEL

The DS-XEL control system is the new standard for extruder controls. The XEL features a high performance design approach that helps users be more productive by highlighting extruder key performance data and streamlining operating

features. It also supports connectivity to supervisory systems to allow users to collect real-time data for their manufacturing execution system (MES) or asset performance management (APM) systems.

High-performance HMI design philosophy for enhanced operator experience. Allows operators to focus on relevant controls and data.

- Built in security to prevent unauthorized changes to system setup parameters.

- Multi-Language support built in.

- OPC-UA for easy supervisor system connectivity.

- Safety integrated into the PLC control system.

- Process alarm logging.

- Real time and historical trending.

- Data logging

- Recipe creation for product repeatability.

- IIoT licensing MQtt protocol

- Heater zone alarming – deviation, process, power fail, load fail, T/C break

- Monitoring of individual zone heater current draw

- Auto and Self tuning options per zone

- Extruder maintenance run timer

- Bar graph display of speed deviation from setpoint

- Min/Max and average motor load during a run

DS-Tablet

Davis-Standard’s hand-held operator interface – the DS Tablet – is a convenient option available with the EPIC III® (iFIX) system. It features:

- 10.4-inch touch-screen

- Wireless connection to EPIC III®

- Windows embedded software

- Docking station, USB ports, charger, and solid-state drive

- Rugged design for industrial environment

- Operator access functions while in areas not practical for typical OCS locations

- Concurrent remote viewing of EPIC III® on office PC with Internet Explorer®

Other advantages of the DS Tablet include:

- A process control screen similar to the EPIC III®

- Temperature screens to change set-point

- Line control screens to change drive set-points

- Ability to create, select and view historical trend groups (historical data is stored on the EPIC III®)

- Viewing and acknowledgment of new and current alarm settings

- Print reports at the EPIC III®

- Security for engineer, supervisor and operator groups

ReACT Support System

Using the ReACT support system customers can enjoy high-speed remote troubleshooting support from Davis-Standard via a secure Internet connection. This system provides real-time viewing and control of EPIC III® screens and PLC systems without affecting the current application. It also provides a faster response to customer needs regarding EPIC III®/PLC controls or process issues.

- Uses standard Internet Explorer®

- Service is intended for troubleshooting and process support

- Works using a third hard drive, which is connected by the customer when support is needed

MACO® 6500RSE

This cost-effective system, an upgrade from the MACO® 6500RS introduced in 2005, is available for retrofit to existing systems. It offers a number of enhancements including screen updates nearly three times faster than older systems. The Operator’s Graphical User Interface has been upgraded to Wonderware® 8.0 and Windows® XP Professional that communicate with the PLC over two separate servers instead of one. This allows for transmission of set points over one server while values are transmitted over another, saving time and improving functionality.

Other significant upgrades include machine screens in several languages, an upgraded setpoint change log to track changes made by the machine operators, a Statistical Process Control program to continuously track 34 items each cycle, and a recipe “save” function to verify recipe names and eliminate the potential for lost recipes. A new “Heat Soak” feature reduces the chances for a cold start-up by requiring machines to be above the low-temperature alarm for at least two hours before the extruder and head tooling programming hydraulics will run. In addition, now both the PLC and Operator’s Station have an uninterruptible power supply to keep them from shutting off during momentary power failures.

As with the MACO® 6500RS, this system includes closed-loop synchronous shoot/fill, adaptive speed control and a PLC ladder logic that can be viewed in real time. Davis-Standard also offers a range of on-site training programs as well as 24/7 telephone service. Especially advantageous is the availability of real-time computer-direct machine service through the Internet.

No post found

READ MORE

Looking for a high output reprocessing solution? Davis Standard’s extrusion capabilities for reprocessing combine innovative technologies for recycling the waste stream into a reusable product.

Our range of single screw and twin screw compounding and reprocessing systems address key efficiency factors such as: solids feeding and conveying, venting and devolatilization, compression and melting, polymer homogenization, and process controls.

Within our extrusion recycling technology line is scrap-reclaim and wide-mouth feed technology, ram stuffer and scrapper extruder options and complete reclaim systems. Heavy-duty gear reducers, customized feed throats, single or multi-venting options and process feed systems are just a few ways we can give you a competitive advantage.

Film Reprocessing

In the area of extrusion technology for film reprocessing, Davis-Standard supplies extrusion systems that offer versatility for turning low bulk density film waste into a useable product. Extrusion systems typically include the extruder, a melt filtration device, pelletizing unit and material handling system. Material size reduction and transfer conveyors can be customized depending on application. Our relationships with major melt filtration and pelletizing suppliers ensure system continuity.

Our Ram Stuffer extruder model is specifically designed for processing the broadest range of feed stocks. This includes everything from light bulk density fluff to shredded flakes, and even heavy bulk density, regrind materials. The Ram Stuffer extruder uses a pneumatically actuated plunger to force the material into the feed section of the screw. The feed section has grooved technology to enhance the conveying of the feed material into the extruder barrel. In a similar way, our scrap reclaim extruder model uses the same wide mouth feed throat design as the Ram Stuffer without the pneumatic plunger. This affords a lower cost alternative when the feed material is slightly heavier in bulk density.

Typical Specifications

Applications - Stretch wrap, agricultural film, construction film, packaging film, general films, barrier and non-barrier, mono and multilayer films

Bulk Density - 32 to 400 kg/m3 / 2 to 25 lbs/ft3

Materials - Polyethylene, Polypropylene

Extruder Outputs - Up to 2700 kg/hr / Up to 6000 lbs/hr

Features - Wide range of line equipment solutions to suit customer's requirements and budgets, latest controls systems, full lines and systematic upgrade/retrofits

Foam Reprocessing

Davis-Standard supports the foam producer or recycler with innovative engineering and proven extrusion technology. Our extruders accommodate different requirements for reprocessing/recycling low bulk density foam waste into a reusable product in a cost-effective manner. We have relationships with major suppliers in the melt filtration and pelletizing market to provide integrated solutions.

Our signature Scrapper dual diameter extruder model is specifically designed to process low bulk density feed stocks, typically from XPS board shavings and millings. The Scrapper uses a large diameter feed section to allow this product to be processed at the highest output rates. This extrusion design incorporates grooved feed technology to more efficiently convey the feed material into the extruder barrel. As a lower cost alternative, we offer a foam scrap reclaim extruder for processing materials with a heavier bulk density such as thermoformed meat trays, plates and cups. These machines incorporate a tangential feed section and also use grooved feed technology to ensure efficient processing.

Typical Specifications

Applications - Foam board, foam sheet, edge regrind, thermoforming skeletons, roll waste

Bulk Density - 48 to 190 kg/m3 / 4 to 12 lbs/ft3

Materials - Polystyrene, Polyethylene, Polypropylene

Extruder Outputs - Up to 1000 kg/hr for the Scrapper and foam scrap reclaim units / Up to 2000 lbs/hr for the Scrapper and foam scrap reclaim units

Features - Wide range of line equipment solutions to suit customer's requirements and budgets, latest controls systems, full lines and systematic upgrade/retrofits

General Reprocessing

Davis-Standard’s reprocessing capabilities combine innovative extrusion technology with multiple options for reprocessing/recycling the waste stream into a reusable product. Our extruders are available in several designs to accommodate a wide variety of waste materials and add profitability to your operation. We supply specialty designs for low bulk density materials as well as more traditional designs to allow processing of irregular shaped chip, flake and regrind.

Our reclaim extruder models are capable of processing bulk density feedstocks, typically from injection molding, blow molding, sheet production and thermoforming processes. An oversized feed section allows irregular shaped feedstock to be processed at the highest possible output rates. We have several design options which enable us to optimize the extrusion system for a given material and application.

Typical Specifications

Applications - injection runners, foam sheet, edge regrind, thermoforming skeletons, roll waste

Bulk Density - 48 to 190 kg/m3 4 to 12 lbs/ft3

Materials - Polystyrene, Polyethylene, Polypropylene

Extruder Outputs - Up to 1000 kg/hr for the Scrapper and foam scrap reclaim units / Up to 2000 lbs/hr for the Scrapper and foam scrap reclaim units

Features - Wide range of line equipment solutions to suit customer's requirements and budgets, latest controls systems, full lines and systematic upgrade/retrofits

No post found

READ MORE

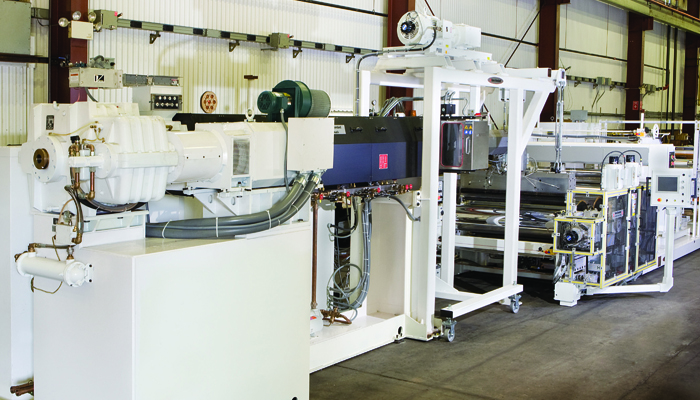

Davis-Standard’s international presence as a premier supplier of sheet extrusion machinery reaches customers in the automotive, construction, industrial and recreational markets, foodservice industry, and those in high-end medical and personal care applications.

Our signature XP Express® and EX-M-PLAR® series roll stands, chill roll technology, feedscrew designs, and coextrusion knowledge enable value-added manufacturing of multi-layer sheet. This includes heavy gauge, high-density PE, low-density PE, PMMA, PS, ABS, PP, PET, high barrier and high-temperature sheet.

We’ve engineered sheet systems for foam, flexible and rigid sheet extrusion for applications up to nine layers. Bring us your idea and we’ll deliver the solution.

Part of Davis-Standard, Thermoforming Systems LLC (TSL) designs, manufactures and markets leading-edge thermoforming equipment to the North American food packaging industry. TSL is the market leader in thermoforming equipment technology for high-volume packaging. TSL solves thermoforming challenges by providing the appropriate products and services that are quantifiably superior to other options. Alongside Davis-Standard, TSL has a variety of manufacturers in the extrusion, tooling, automation, and granulating industries in the USA and worldwide to offer full project services, providing the end customer with a single point of contact for their project.

Disposable & Food Service Packaging (HIPS, PP and PET)

Davis-Standard has years of experience supplying complete turnkey sheet extrusion lines for sheet utilized in thermoformed packaging. Our experience and capabilities include:

- In-line and off-line thermoforming sheet designs

- High speed extrusion systems

- Non-dried and dried APET sheet solutions

- On-line low bulk-density scrap re-processing capabilities

- Single lane or multilane extrusion to maximum cooling performance

- Special FFS quality sheet line designs

- Special nipping and non-nipping auxiliary cooling carts.

We understand the importance of each piece of equipment on a sheet line and offer a wide range of DS-built and DS-specified equipment with experienced partners. Our application engineering is second to none and we work with each customer to deliver a sheet solution that will meet their production demands.

Bigger and faster sheet lines require most sophisticated controls and our DS-eVue and EPICIII® control systems allow complete line control, with the following benefits:

- Touch-screen displays with complete line overview, detailed extruder data, recipe creation, etc

- ControlLogix or Siemens PLC platform

- Connectivity solutions for remote data access via laptop and Web browsing

- Multi-level security system to protect set-up functions and accessibility

Typical Specifications

Applications - Thermoformed packaging, Form Fill Seal (FFS) packaging

Line Speed Range - 1.5 to 60 mpm / 5 to 200 fpm

Size Range - 0.25 to 2.5 mm / 0.010 to 0.100 inch

Materials - HIPS, PP and PET

Density Reduction & Filled Sheet (High Density Foam, Polymer Replacement)

Achieving cost reduction is our goal for applications in the packaging, automotive, appliance, building products and consumer products industries. One of the best ways to do this for sheet applications is through density reduction and/or the use of lower cost fillers. Davis-Standard offers sheet and foam application engineering that is second to none, working with experienced partners to ensure customers have the system their process demands. This includes chemical and physical blowing agent system that allow for material savings of five to 30 percent, as well as systems for feeding talc, CaCO3 and other fillers.

Typical Specifications

Applications - Thermoformed packaging, form fill seal (FFS) packaging, insulating sheet

Line Speed Range - 1.5 to 90 mpm / 5 to 300 fpm

Thickness Range - 0.25 to 2.5mm / 0.010 to 0.100 inches

Materials - HIPS, PP, PE, HDPE and PET

Appliance & High Quality Electronics Sheet (HIPS, ABS, Acrylic (PMMA), PC, PETG)

Appliance and high-quality electronic sheet applications demand perfection. Davis-Standard has extensive experience in this area. We supply sheet systems that achieve high-quality surface finishes and that utilize engineering plastics to deliver required physical property performance. This includes sophisticated controls for bigger and faster sheet lines.

Advantages include on-line low bulk-density scrap reprocessing capabilities, single lane or multi-lane extrusion for optimal cooling performance, and high-speed stacking systems to accommodate maximum available output and cooling.

Typical Specifications

Applications - Signage, POS/PPS displays, LCD screen components, lighting and white goods

Line Speed Range - 0.5 to 30 mpm / 1 to 100 fpm

Size Range - 0.25 to 12mm / 0.010 to 0.500 inches

Materials - HIPS, ABS, Acrylic (PMMA), PC, PETG

Heavy Gauge Industrial Sheet for Marine and Automotive (HMWHDPE, PP, PMMA)

Davis-Standard’s innovative extrusion design engineering and extensive field experience enable us to supply proven technology for plastic sheet utilized in heavy sheet applications for the marine and automotive industries. In addition to Davis-Standard engineered technology, we have trusted relationships with industry partners who augment our lines with specified equipment needed to support our customer’s production demands. This coupled with our extensive control system capabilities give our customers peace of mind knowing that they can come to a single source for the heavy gauge sheet requirements.

Advantages of our sheet extrusion equipment include capabilities for producing heavy gauge sheet from 1/2 to 3-inch thicknesses, an online lamination system to allow quick pattern changes, single or multi-lane extrusion for maximum cooling performance, and high-speed stacking systems to accommodate maximum available output and cooling.

Typical Specifications

Applications - Wall partitions, canoes, fender wells/guards, cutting boards, marine applications

Line Speed Range - 0.25 to 3 mpm / 0.5 to 20 fpm

Thickness Range - 12 to 75mm / 1/2 to 3 inches

Materials - HMWHDPE, PP, PMMA

Roofing and Coating Sheet Lines (TPO, FPVC, PP, PE)

Davis-Standard has over 40 years experience supplying complete turnkey sheet extrusion machinery solutions for roofing and coating sheet applications. In addition to versatile equipment options, we supply control systems to support processing efficiency and user-friendly machine operation.

Our sheet extrusion capabilities for roofing lines include direct in-line compounding or single screw extrusion systems (TPO and FPVC) for roofing and waterproof membranes. Advantages include innovative designs for heat-sensitive formulations, process verification capability prior to machine production, customized widths based on output rates and variable width requirements, and multiple unwind and secondary substrate laminating capability.

For automotive and industrial carpet lines we supply carpet back extrusion coating systems (PE, FPVC, TPO) for commercial carpet and tile carpet applications as well as automotive floor mat and sound attenuation applications. Our thermoplastic extrusion process replaces solution latex coating processes. Advantages include high output extrusion rates for efficient processing, energy savings through reduced solution-based product drying, and a smaller footprint. High material mineral fill levels also reduce production costs as does the addition of recyclable content.

Typical Specifications

Applications - Roofing membrane, waterproof membrane, geotextiles, banner/signage

Line Speed Range - 1.5 to 90 mpm / 5 to 300 fpm

Thickness Range - 0.25 to 2.5 mm / 0.010 to 0.100 inch

Materials - TPO, FPVC, PP, PE

Clear Sheet for PPE Applications

With continued growth in the PPE marketplace due to COVID-19, Davis-Standard is equipped to supply new line capabilities or upgrade existing lines. A variety of PPE resins can be processed on most sheet lines with a few modifications. Our extruders, melt pumps, dies, and roll stands offer the versatility needed for making FDA approved clear plastic sheet in a cost-effective manner. Factors such as extruder torque, optimized screw design, machine direction thickness control, dies built for specific resins, and the right roll stand configuration all contribute to a more efficient PPE sheet process and desired outputs.

Equipment advantages include extended field range motors, vented and plugged extruder barrels, controlled leakage flow, reduced pressure variability, preferred die features, vertical downstack, J-stack and horizontal stack roll stands, and a range of control system technology. Our team is available to evaluate existing capabilities and make recommendations based on application or quote a new system, sized to meet your needs.

Typical Specifications

Applications – Barrier guards, Face shields and protective devices, disposable healthcare products.

Materials – PET, PETG, PMMA, PC, CPS, PP

Lab Scale Equipment

Davis-Standard offers a comprehensive line of laboratory and pilot-scale equipment designed to meet sheet processing requirements for product development, polymer research, material testing, and validation. This includes extruders, process controls, feedscrew technology, and

roll stand options. Single or multi-layer laboratory systems are available as well as individual components. Sturdy and reliable construction simulates production performance and accuracy. Advantages include:

Vertical Down Or Horizontal Stack Configurations:

- Stack width from 8”-24”

- Roll diameter from 5”-12”

- Stack rolls can be driven individually or with single chain drive

- Pneumatic or hydraulic nip pressure

- Touch screen control of independent stack drives

- Independent torque and speed control available

- Meets ANSI B 151.20 sheet safety standards

- Options: high-temperature rolls, slitting, substrate pay-off, corona treating, stack rolls with alternate finish, and on-line thickness gauge

Typical Specifications

Line Speed Range – 1-20fpm

Thickness Range – .005”-.125”

Materials – Typical thermoplastics and engineered resins

EDI® Prodigi™ Die System

As a world class equipment supplier and preferred business partner of EDI®, Davis-Standard is pleased to be the systems integrator for the new Prodigi™ die systems. Using this die technology, converting customers have the opportunity to boost converting performance at a significant cost savings. This patent-pending motorized lip actuator system allows for faster APC control achieving spec in 3-4 times faster than thermal bolt dies.

- Improve team safety

- Greater energy savings

- Optimal repeatability

- Faster set-up speed

- Gain additional stroke

- Results validated

No post found

READ MORE

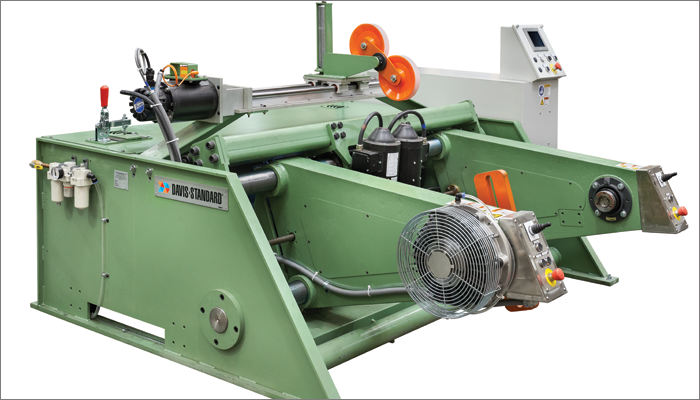

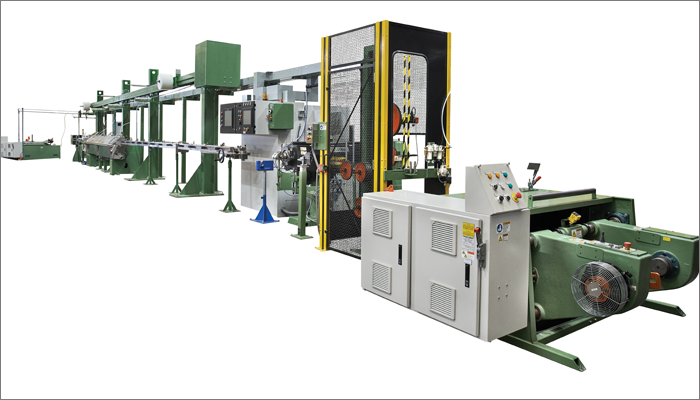

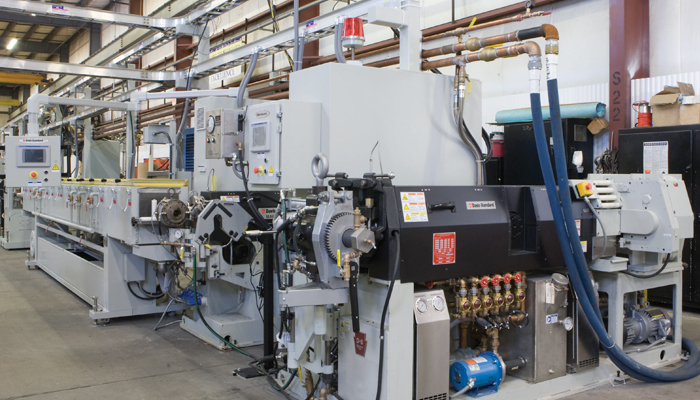

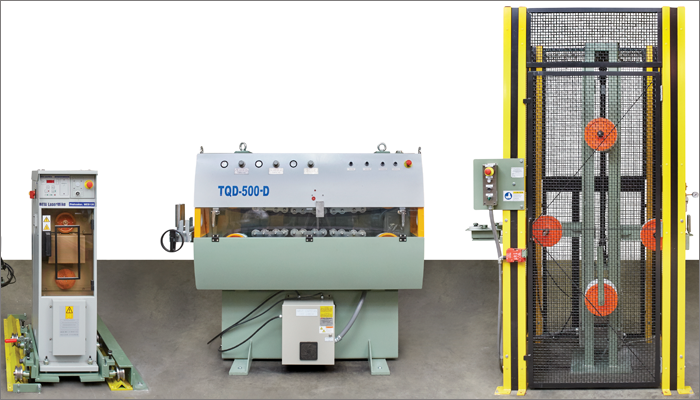

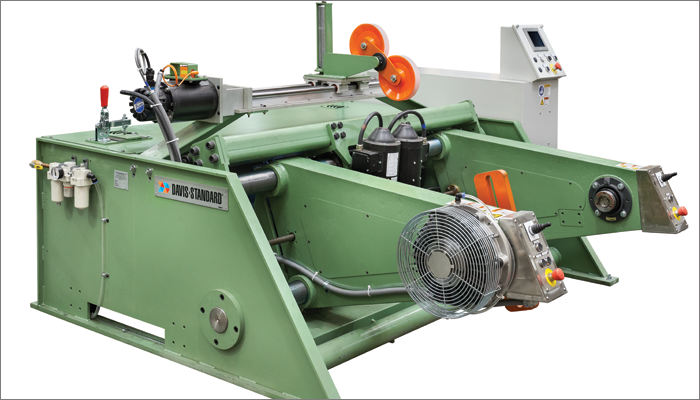

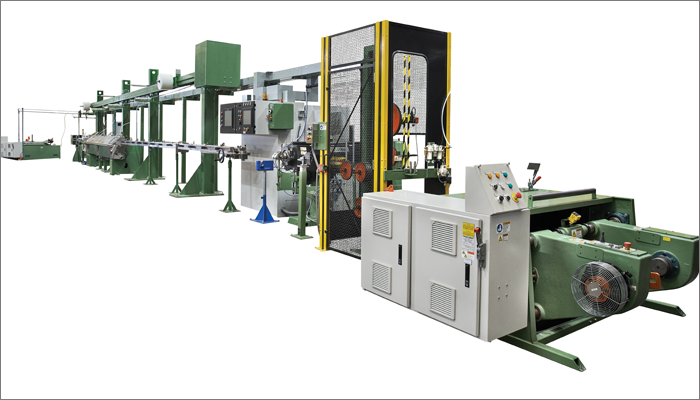

For more than 60 years, Davis-Standard has been at the forefront of wire and cable extrusion in the building and construction, automotive, power cable and communication wire industries.

Our extensive line of wire and cable extruders—along with payoffs and takeups, accumulators, cooling systems and capstans—enable us to offer one-stop shopping. Our extruders are the workhorses of the industry. Our depth of wire and cable extrusion knowledge and experience is unsurpassed in the wire and cable industry.

Aerial cable, building wire, coaxial and composite cable, video pair cable, tray cable, CATV, THHN and THWN wire are just a few applications accommodated by our wire and cable machinery.

For more information on Maillefer Wire and Cable machinery, please visit here.

Aerospace Wire

Davis-Standard has been an innovator in developing high-temperature aerospace wire extrusion systems with the ability to produce lighter and stronger products. Cost cutting solutions have come in the form of weight reduction, smaller diameters and greater flexibility.

Davis Standard offers the option of built-to-order extrusion systems with the performance and dependability of field-proven designs.

Typical Aerospace Wire System Components:

- Single Reel 630mm Shaftless Payoff

- Low Tension Dancer

- Preheater

- Inner Layer Extruder, 1.25-inch (32mm) 24:1 L/D

- Gravimetric Blender

- Precision Fixed Center Crosshead

- Spark Tester, 15KV

- Skip Detector

- Vacuum Pump

- Scrap Capstan

- Outer Layer Extruder 1.50-inch (38mm) 24:1 L/D

- Precision Fixed Center Crosshead

- Gravimetric Blender

- Spark Tester, 15KV

- Cooling System

- Belt Wrap Capstan

- Diameter Measuring Dual Plane with flaw Detection and Concentricity

- Wire Damager

- Low Tension Vertical Accumulator

- Dual position 630mm Take-up

- Control System: EPIC III®

Typical Specifications

Conductor - 10 – 30 AWG, 16 AWG = 19/.287 1.44 mm OD, 26 AWG = 19/.102 / 0.51 mm OD

Conductor Type - Stranded Copper / Copper Alloys /Silver Alloy / Nickel Alloy

Insulating Materials - 38mm Extruder: ETFE/X-ETFE (TAIC Compounded) / 1.5-inch Extruder: ETFE/X-ETFE (TAIC Compounded) / 32mm Extruder: ETFE/X-ETFE (TAIC Compounded) / 1.25-inch Extruder: ETFE/X-ETFE (TAIC Compounded)

Wall Thickness Range - 0.076 to 0.30mm

Outside Diameter Range - 0.67 to 4.4mm

Line Speed - 15 - 210 mpm

Automotive Wire

Davis-Standard is a global leader in supplying high-speed automotive wire insulating extrusion lines to produce low-voltage automotive cables for signals, pressure gauges, lights, lighters, alarms and controls. These lines, available from 19 to 24-gauge, are engineered for reliable performance and consistent quality. Both standard thermoplastic materials and cross-linked flame retardant polyethylene (XLPE and HFFR) can be processed utilizing Slant Line CV technology. Automatic color change systems for primary insulation, skin and striping minimize scrap while maximizing production.

Typical Automotive Wire System Components:

- Dual Flyer Pay-Off

- Input Capstan with Tension Control

- Preheater

- Primary Extruder, 2.5-inch (64mm) 24:1 L/D

- Secondary Extruder 1.5-inch (38mm) 24:1 L/D Horizontal or Vertical

- Dosing System Volumetric / Gravimetric

- Quick Color Change System

- Diameter Measuring Dual Plane

- Spark Tester, 15KV

- Diameter Measuring Dual Plane

- Multi-Pass or Regular Capstan (based on type of take-up

- Take-Up System Dual Reel, NPS System, Barrel Packer

- Control System: EPIC III®

Typical Specifications

Conductor - Flexible copper: 0.22 - 7mm2 / Flexible copper: 26 awg - 10 awg

Diameter Over Insulation - Up to 5.5mm / Up to 0.216 inches

Maximum Line Speed - 1500 mpm / 5000 fpm

Power Cable

In the area of power cable, Davis-Standard designs and manufactures both steam and dry cure extrusion systems (to 35 kVA). Steam extrusion systems are best suited for a minimum investment, and for extrusion compounds not formulated for high-temperature curing. This equipment processes rubber, XLPE, and regular thermoplastic polyethylene without changing a major piece of equipment. A nitrogen extrusion system (dry cure) provides a fast and economical option for thermoset insulations, particularly XLPE.

Typical Specifications

Conductor - Copper/aluminium, 0,5 - 500 mm²

Conductor Design - Round and sector shaped

Diameter Over Insulation - Up to 45mm / Up to 1.8 inches

Maximum Line Speed - Up to 1200 mpm / Up to 3840 fpm

Building Wire

With over 250 installed building wire systems worldwide, Davis-Standard is a market leader. Our high output wire and cable extrusion lines are engineered for insulating single cores and jacketing multi-conductor insulated constructions. These lines are capable of extruding PVC from powder or pellets and can coextrude multi-layer constructions such as nylon over PVC. Our technology also provides continuous operation with packaging of the product in coils, on reels or stem packs.

In addition to supplying fully integrated building wire systems, Davis-Standard specializes in the design and manufacture of components required for high-speed extrusion. All Davis-Standard wire and cable extrusion equipment can be customized to meet individual processor’s needs.

Typical Building Wire System Components:

- Wire Drawing - Dual Flyer Pay-Off

- Input Capstan with Tension Control

- Preheater

- Primary Extruder, 6-inch (152mm) 24:1 L/D

- Secondary Extruder 3 1/2-inch (89mm) 24:1 L/D Horizontal or Vertical

- Dosing System Volumetric / Gravimetric

- Quick Color Change System

- Diameter Measuring Dual Plane

- Spark Tester, 15KV/30KV Diameter

- Measuring Dual Plane

- Multi-Pass or Belt Wrap Capstan (based on conductor size)

- Take-Up System Dual Reel, NPS System, Barrel Packer, Gantry

- Control System: EPIC III®

Typical Specifications

Conductor - Solid and stranded copper: .456 – 506.7 mm² / 22 awg – 1000 mcm

Diameter Over Insulation - Up to 33.5mm / Up to 1.32 inches

Maximum - Line Speed 2590 mpm / 8500 fpm

No post found

READ MORE

Improve Blow Molding Productivity

Davis-Standard offers custom-designed industrial blow molding machinery for a wide range of applications in the automotive and consumer product industries. Our flexible, custom-designed accumulator head blow molding systems feature closed-loop hydraulic and electronic controls and state-of-the-art screw design for processing both polyolefins and engineered thermoplastics.

Davis-Standard’s blow molding technology maximizes productivity with shot consistency, cycle-to-cycle precision, and excellent parison control. Our features, such as spiral head technology for faster color changes and efficient wall distribution, support cost-efficient operation.

Regardless of the blow molding application, Davis-Standard delivers quality molded parts with highly accurate wall thickness and density.

Davis-Standard offers custom designed industrial blow molding machinery to meet your needs. Our flexible, custom designed accumulator head blow molding systems feature closed-loop hydraulic and electronic controls and state-of-the-art screw design for processing both polyolefins and engineered thermoplastics. Unmatched product innovation is driven by large part capabilities.

Features:

- Flexible, custom designed accumulator head blow molding systems

- Closed loop hydraulic and electronic controls

- State-of-the-art screw design for processing both polyolefins and engineered thermoplastics

- Extended machine life with retrofits and rebuilds including OEM quality controls upgrades, ANSI safety compliance, spiral core tube retrofits, head reconditioning, clamp rebuilds, replacement screws and barrels

- Spiral accumulator head technology to eliminate weld (re-knit) lines giving faster color changes and unmatched wall distribution

Retrofits and Rebuilds:

- Extends machine life

- OEM controls upgrades

- ANSI safety compliance

- Spiral core tube retrofits

- Head reconditioning

- Clamp rebuilds

- Replacement screws and barrels

Leading Technology and Innovation for Your Elastomer Extrusion Requirements

Davis-Standard’s elastomer extruders support global markets for tires, automotive hoses, adhesives and sealants, recreational equipment, construction and medical applications. We are industry leaders in complete rubber and silicone technology to support a range of applications including rubber hose, rubber and silicone gaskets, rubber barrier products, silicone tubing and weatherstrip.

With elastomer extruders in multipurpose, hot and cold feed, silicone, vacuum vented, pin barrel and smooth barrel designs, our extensive offering of elastomer systems provides a specific solution for nearly every elastomer application. Our engineers work with you to supply elastomer equipment that meets your precise product requirements, including technology for product curing and in-line processing.

Our advantage lies in decades of experience and knowledge of elastomer properties and processes for coextrusion, rubber straining and continuous vulcanization. That is why we also supply custom feedscrew designs, lab equipment, integrated process controls and complete systems—one-stop shopping for turnkey rubber extrusion.

Davis-Standard has years of experience supplying elastomer extruders, components, and complete systems for automotive seals. Our elastomer customer base is Tier 1 with installations worldwide. We supply duplex, triplex and quadruplex profile heads for supported and unsupported rubber profiles. We are industry leaders in turnkey applications including carrier forming, curing, coating, flocking and cutting/sawing of profiles.

We understand the importance of each component and offer a wide range of Davis-Standard-built and Davis-Standard-specified elastomer equipment with experienced partners. This includes hot air and microwave curing ovens, pre-and post-formers for rigid carrier, flocking booths, cooling tanks, pullers, cutters, laser marking, printing and drilling.

An example of our advanced elastomer technology is our purpose-designed DSREV rubber extruder. Advantages include our patented pneumatic roll feed system to provide uniform, consistent feed rate; electric heat/water-cooled heating for quicker response time, lower maintenance and smaller machine footprint, rugged Davis-Standard gearboxes, and Davis-Standard's proven feedscrew designs to maximize output and minimize scorch.

Typical Specifications

Applications - Single and dual durometer unsupported seals, single and dual durometer supported seals, wire, stamped steel, breakable steel, and rigid steel supported seals

Line Speed Range - 6 to 30 mpm / 20 to 100 fpm

Size Range - 25 to 56 square cm / 1 to 9 square inches

Materials - EPDM Sponge, EPDM Dense, TPV/EPDM Compositions

With elastomer installations worldwide, Davis-Standard offers vast experience in supplying extruders, components, and complete systems for industrial rubber hose. We understand the importance of each component and offer a wide range of Davis-Standard-built and Davis-Standard-specified equipment with experienced partners. This includes laser and x-ray gauge control, pullers and cutters, textile reinforcement, cooling and anti-tack application tanks, adhesion-promoting systems, anti-tack dusting systems, laser-marking, printing and winding.

Examples of our preferred elastomer technology in this area include:

The DS Model 2000 crosshead – Features a tapered mandrel and highly engineered flow paths to ensure equal flow through all line speed ranges; propriety coating on wetted surfaces to increase wear resistance and provide easier clean-out; thrust bearing on pin adjustment to allow wall thickness adjustment without stopping the line; and hydraulic cylinders for quick and easy removal of the mandrel from the head body.

The DSREV rubber extruder – Features our patented pneumatic roll feed system to provide a uniform, consistent feed rate; electric heat/water-cooled heating for quicker response time, lower maintenance and smaller machine footprint; rugged Davis-Standard gearboxes; and proven feedscrew designs to maximize output and minimize scorch.

Typical Specifications

Applications - Composite spiral reinforced hose, composite knit reinforced hose, pole-built, 2-step wire reinforced hydraulic hose, multi-layer specialty fuel/gas hose

Line Speed Range - 1.5 to 100 mpm / 5 to 30 fpm

Size Range - 6 to 115mm / 250 to 4.5 inches

Materials - EPDM, NBR, SBR, FKM, ECO, THV, silicone

Our elastomer systems and rubber extruders for automotive hose are widely used among Tier 1 customers worldwide. We understand the importance of each component and offer a wide range of Davis-Standard-built and Davis-Standard-specified equipment with experienced partners. This includes laser and x-ray gauge control, pullers, cutters, textile reinforcement, cooling and anti-tack application tanks, adhesion-promoting systems, laser marking and printing.

Examples of our preferred technology in this area include:

The DS Model 2000 crosshead – Features a tapered mandrel and highly engineered flow paths to ensure equal flow through all line speed ranges; propriety coating on wetted surfaces to increase wear resistance and provide easier clean-out; thrust bearing on pin adjustment to allow wall thickness adjustment without stopping the line; and hydraulic cylinders for quick and easy removal of the mandrel from the head body.

The DSREV rubber extruder – Features our patented pneumatic roll feed system to provide uniform, consistent feed rate; electric heat/water-cooled heating for quicker response time; lower maintenance and smaller machine footprint; rugged Davis-Standard gearboxes; and proven feedscrew designs to maximize output and minimize scorch.

Typical Specifications

Applications - Coolant hose, radiator hose, multi-layer THV/elastomer non-permeation fuel hose, A/C hose, turbo charger hose, brake hose

Line Speed Range - 1.5 to 30 mpm / 5 to 100 fpm

Size Range - 6 to 115 mm / .250 to 4.5 inches

Materials - EPDM, NBR, SBR, FKM, ECO , THV, silicone

We supply elastomer extruders, components, and complete elastomer systems for large and small continuous cure gasket lines for both rubber and silicone products. We understand the importance of each component and offer a wide range of Davis-Standard-built and Davis-Standard-specified equipment with experienced partners. This includes hot air and microwave curing ovens, salt bath curing tanks, standard and custom cooling tanks, pullers, cutters, laser marking, printing and winding.

An example of our advanced elastomer technology is our purpose-designed DSREV rubber extruder. Advantages include our patented pneumatic roll feed system to a provide uniform, consistent feed rate; electric heat/water-cooled heating for quicker response time; lower maintenance and smaller machine footprint; rugged Davis-Standard gearboxes; and Davis-Standard's proven feedscrew designs to maximize output and minimize scorch.

Typical Specifications

Applications - Coolant hose, radiator hose, multi-layer THV/Elastomer non-permeation fuel hose, A/C hose, turbocharger hose, brake hose

Line Speed Range - 1.5 to 30 mpm / 5 to 100 fpm

Size Range - 6 to 115mm / .250 to 4.5 inches

Materials - EPDM, NBR, SBR, FKM, ECO , THV, silicone

Davis-Standard has extensive process and extrusion expertise in the area of medical and industrial silicone tubing worldwide. We understand there is a difference between extruding an industrial fluid transfer tube and extruding an infantile catheter. Our engineers work with you to supply the correct customized equipment to meet your precise product requirements including horizontal or vertical extrusion, short-wave or medium-wave cure systems, custom designed dies and downstream equipment, or precision cutting and winding.

An example of our preferred extrusion technology in this area includes our DSR silicone extruder. Advantages include our patented pneumatic roll feed system to provide uniform, consistent feed rate, chrome plating and stainless steel contact surfaces for medical environments, available hinge-roll feed roll section for easy cleanout and compound changes, rugged Davis-Standard gearboxes, and proven feedscrew designs to maximize output and stability.

Typical Specifications

Applications - Medical silicone catheters, wound drainage tubing, specialized tubing, Medical silicone tubing (multi-lumen), radio-opaque stripe, farm/dairy silicone tubing and multi-layer hose, industrial silicone tubing, specialty silicone gaskets

Line Speed Range - 1.5 to 23 mpm / 5 to 75 fpm

Size Range - 2.5 to 50mm / 100 to 2 inches

Materials - Medical and industrial grade silicone compounds, heavily filled, conductive silicone compounds

- Tapered mandrel designed for stable concentricity

- Engineered flow path through head maintains equal flow across speed ranges

- Rigid die holder maintains concentricity adjustment when dies are changed

- Die adjusting screws are in removable inserts to protect body from thread damage

- Thrust bearing allows easy pin adjustment to change wall thickness

- Larger surface area in water jacket for better heat transfer

- Manufactured from AISI 4140 heat treated steel with all inside surfaces coated with Armalloy for improved wear resistance, material flow, and clean-out

- Hydraulic mandrel removal with air operated hydraulic pump and control valve

- Mandrel swings/slides out

- Standard models available to cover 2” (50mm), 3” (76mm), 4.5” (102mm) and 5.5” (140mm) diameter braid

- 2” and 3” models include pintle mount on a Davis-Standard hinge and scissor-arm support for mandrel removal; 4.5” and 5.5” model includes support cart with mandrel removal facilitated by linear rails on the cart

The Model 3000A incorporates an automatic, servo-driven concentricity adjustment system. This new, proprietary system allows for adjustment of the core tube/tip assembly with simple, accurate joystick control. This enables the operator to easily minimize eccentricity, maximize concentricity, and reduce downtime during product changeovers. In addition, the servo drives enable monitoring and adjustments throughout the run to account for lot-to-lot variations, day/night variations, and gum space corrections. The compact design does not require a hydraulic pump system or hoses.

- Tapered mandrel designed for stable concentricity

- Engineered flow path through head maintains equal flow across speed ranges

- Rigid die holder maintains concentricity adjustment when dies are changed

- Die-adjusting screws are in removable inserts to protect body from thread damage

- Thrust bearing allows easy pin adjustment to change wall thickness

- Larger surface area in water jacket for better heat transfer

- Manufactured from AISI 4140 heat treated steel with all inside surfaces coated with Armalloy for improved wear resistance, material flow, and clean-out

- Hydraulic mandrel removal with air-operated hydraulic pump and control valve

- Mandrel swings/slides out and is supported for safe and easy cleaning

- Standard models available to cover 2” (50mm), 3” (76mm), 4.5” (102mm) and 5.5” (140mm) diameter braid

- 2” and 3” models include pintle mount on a Davis-Standard hinge and scissor-arm support for mandrel removal

- 4.5” and 5.5” models include support cart with mandrel removal facilitated by linear rails on the cart

The Model 4000AG incorporates an automatic, servo-driven concentricity and wall thickness adjustment system. This new, proprietary system allows for adjustment of the core tube/tip assembly with simple, accurate joystick control. This enables the operator to easily minimize eccentricity, maximize concentricity, and reduce downtime during product changeovers.

In addition, the servo drives enable monitoring and adjustments throughout the run to account for lot-to-lot variations, day/night variations, and wall thickness corrections.

The compact design does not require a hydraulic pump system or hoses. This system also includes stepper-driven wall thickness adjustment, eliminating the requirement of hand tools and intrusive thickness measuring devices.

Additional features such as a tapered mandrel and highly-engineered flow paths ensure consistent flow through all speed ranges. Heat transfer efficiency has been optimized by using computer analyzed software for design of water-cooling jacket.