Pelletizing Precision and Consistency

Davis-Standard helps customers achieve high quality pellets through field-tested experience in underwater pelletizing, water ring pelletizing and air ring pelletizing processes. Our modular extrusion and pelletizing solutions are ideal for conventional, micro and macro pellet production.

Our engineers address key factors in pelletizing equipment design to ensure consistent melt temperature, melt flow index and melt pressure throughout the pelletizing process. We also offer more model sizes and multiple options for screen changers, heating systems, dryers, and water systems to ensure greater efficiency, value and quality.

How can we help you?

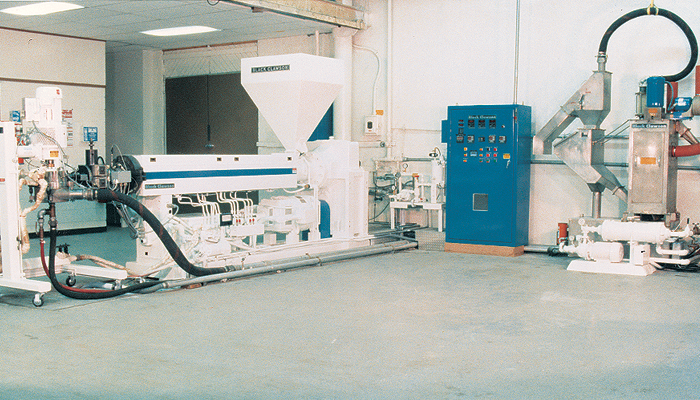

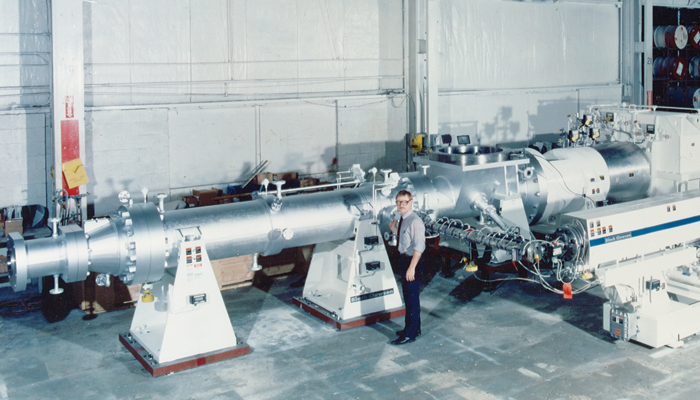

Modular Davis-Standard pelletizing systems can be designed to receive solid or molten feed material for all polymer types and processes. Selecting the best and proper extrusion equipment technology to meet your virgin resin production, compounding, scrap reclaim or other processing needs is an important factor for profitability. Our systems come in a full range of model sizes and equipment types, giving you the freedom to build your pelletizing line around the components needed for your requirements.

All subsystem and support equipment such as screen changers, diverter valves, heating systems, classifiers, dryers, water systems, control panels can be included to provide a total system concept. Product can be fed from a reactor, holding vessel, single or twin screw extruder, continuous mixer, mill, gear pump or other feed devices. Additives can be incorporated and mixed with the main product through a feed port, injection pump, or satellite side arm extruder. Degassing of volatiles or product filtration may be included where required. The product is then discharged to the downstream pelletizing equipment on a continuous basis. The end result is superior quality, highly reliable machine lines that turn pellets into bigger profits for you.

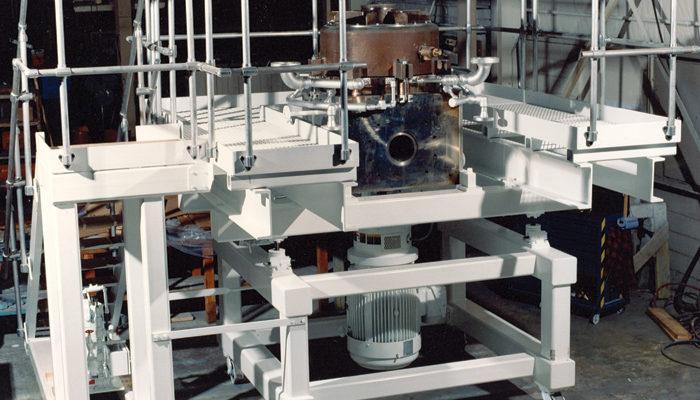

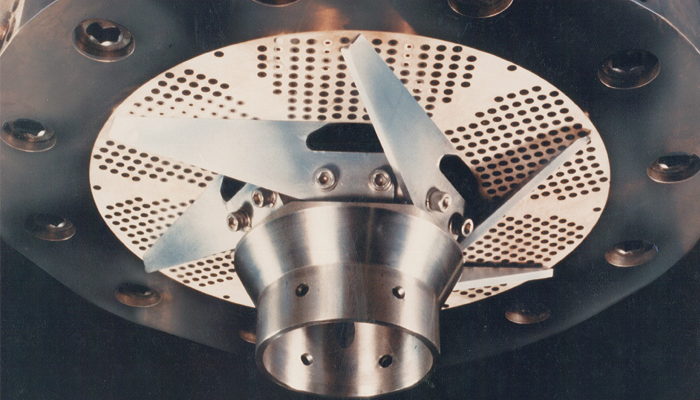

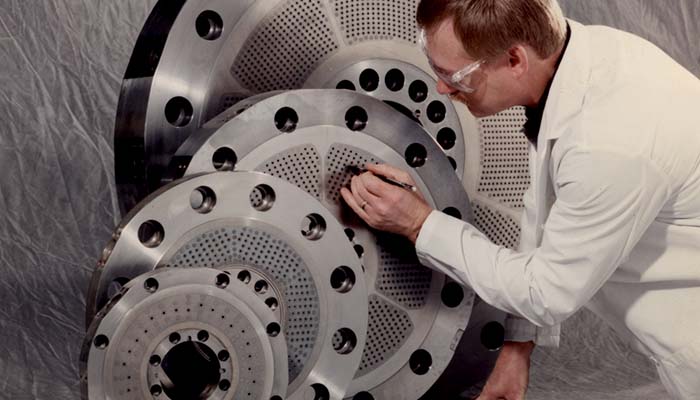

Davis-Standard’s universal underwater system – the Pelletor® - offers everything you need to produce high-quality, uniform pellets. We offer several options to conventional, micro or macro pellet production using unique designs. These designs assure perfect knife-to-die plate alignment regardless of thermal or mechanical variation of the feed equipment. Very broad product viscosity ranges may be easily achieved.

The Pelletor works in either underwater, water or air ring cutting methods or both. Solution oriented options and features allow ease of operation, highest processing performance, and highest product quality. Since we offer a full range of model sizes, you have the freedom to build your pelletizing line around the system components that meet your exact criteria. All subsystem and support equipment such as screen changers, diverter valves, heating systems, classifiers, dryers, water systems and control panels may be included to provide a total system concept. The end result is superior quality and highly reliable machine lines that turn pellets into bigger profits for you.

Typical Specifications

| Size | Max No. Holes | Typical Drive | Power Nominal | Thruput | Rates/Hour |

|---|---|---|---|---|---|

| 0.5 | 40 | 10 hp | 7.5 kw | 1,200 lbs | 545 kgs |

| 1 | 151 | 10 hp | 7.5 kw | 4,530 lbs | 2,054 kgs |

| 2 | 204 | 15 hp | 11.2 kw | 6,120 lbs | 2,775 kgs |

| 2x | 420 | 15 hp | 7.5 kw | 7,200 lbs | 3,264 kgs |

| 3.5 | 270 | 20 hp | 15 kw | 8,100 lbs | 3,680 kgs |

| 3 | 270 | 20 hp | 15 kw | 8,100 lbs | 3,680 kgs |

| 3x | 372 | 20 hp | 15 kw | 11,160 lbs | 5,060 kgs |

| 6 | 714 | 50 hp | 37 kw | 21,400 lbs | 9,710 kgs |

| 6x | 840 | 75 hp | 56 kw | 25,200 lbs | 11,424 kgs |

| 8 | 992 | 100 hp | 75 kw | 29,760 lbs | 13,520 kgs |

| 8x | 1352 | 100 hp | 75 kw | 40,560 lbs | 18,436 kgs |

| 10 | 1880 | 125 hp | 93 kw | 56,400 lbs | 25,568 kgs |

| 10x | 2320 | 150 hp | 112 kw | 69,600 lbs | 31,552 kgs |

| 12 | 2368 | 200 hp | 150 kw | 71,040 lbs | 32,290 kgs |

| 12x | 2784 | 200 hp | 150 kw | 83,520 lbs | 37,964 kgs |

| 14 | 2920 | 250 hp | 187 kw | 87,600 lbs | 39,820 kgs |

| 14x | 3600 | 250 hp | 187 kw | 108,000 lbs | 49,090 kgs |

| 16 | 4200 | 300 hp | 224 kw | 126,000 lbs | 52,273 kgs |

NOTE: Die plate orifice hole size has a great impact on output of any given type of polymer produced on a given machine size. The above chart is based on 30 lbs (13.6 kgs) per hour per hole.

Davis-Standard’s universal underwater system – the Pelletor® offers everything you need to produce high-quality, uniform pellets. We offer several options to conventional, micro or macro pellet production using unique designs. These designs assure perfect knife-to-die plate alignment regardless of thermal or mechanical variation of the feed equipment. Very broad product viscosity ranges may be easily achieved.

The Pelletor works in either underwater, water or air ring cutting methods or both. Solution oriented options and features allow ease of operation, highest processing performance, and highest product quality. Since we offer a full range of model sizes, you have the freedom to build your pelletizing line around the system components that meet your exact criteria. All subsystem and support equipment such as screen changers, diverter valves, heating systems, classifiers, dryers, water systems and control panels may be included to provide a total system concept. The end result is superior quality and highly reliable machine lines that turn pellets into bigger profits for you.

Typical Specifications

| Size | Max No. Holes | Typical Drive | Power | Nominal Throughput | Rates/Hour |

|---|---|---|---|---|---|

| 0.5 | 40 | 5 hp | 3.75 kw | 1,200 lbs | 545 kgs |

| 1 | 87 | 5 hp | 3.75 kw | 2610 lbs | 1,186 kgs |

| 2 | 204 | 10 hp | 7.5 kw | 6,120 lbs | 2,775 kgs |

| 2x | 240 | 10 hp | 7.5 kw | 7,200 lbs | 3,264 kgs |

| 3.5 | 270 | 15 hp | 11.2 kw | 8,100 lbs | 3,680 kgs |

| 3 | 270 | 15 hp | 11.2 kw | 8,100 lbs | 3,680 kgs |

| 3x | 372 | 15 hp | 11.2 kw | 11,160 lbs | 5,060 kgs |

| 6 | 500 | 20 hp | 15 kw | 15,000 lbs | 6,820 kgs |

| 6x | 810 | 30 hp | 22.4 kw | 24,300 lbs | 11,016 kgs |

NOTE: Die plate orifice hole size has a great impact on output of any given type of polymer produced on a given machine size. The above chart is based on 30 lbs (13.6 kgs) per hour per hole.