Flexible and Customized Extrusion Control Solutions for Every Process

The brain of the extruder drives your operation and smarter process controls make a huge impact on the bottom line. That is why every system in Davis-Standard’s full line of process controls is operator-friendly, efficient and reliable. From discrete to full supervisory control, our control systems are engineered in-house to ensure quality and value.

Davis-Standard’s proven systems do the thinking for you about systems integration, temperature control and process controls.

The Integrator Pro+™ is the successor to Davis-Standard’s existing Integrator Pro human-machine interface (HMI) for high-level blown film, cast film, extrusion coating, drying, solvent, and aqueous coating processes. This system supports the DS Activ-Check™ digital transformation platform, which offers a powerful suite of analytical tools, cloud and local data storage options, and process and equipment technology algorithms.

The Integrator Pro+ delivers all the valued features of the previous version such as recipe recall, intuitive interface and control functions, custom reporting and line drive functionality, while further facilitating user-friendliness, mobility and process efficiency outcomes.

Advantages include:

- Opportunity to integrate DS Activ-Check™ digital transformation tool

- Central control of all production parameters

- Process data analysis and assistance with overall equipment effectiveness (OEE)

- Compatibility with obsolete controls installed on legacy Davis-Standard machinery

- Increased storage, troubleshooting, and analysis capability

- Process data trending increased to two years (Integrator Pro is one year)

- Minimum of 10 trending screens (Integrator Pro is five years)

- Minimum of last 1,000 events (Integrator Pro is 500 events)

- Ease of use and navigation with an intuitive HMI

- Increased user-friendliness

- Additional modes of viewing (mobility)

- Improved graphics

- Streamlined visual displays of relevant process information

- Safety overview screen illustrating status of imbedded safety devices to aid in diagnostics and troubleshooting

- Omni situational awareness for seamless and secure portability of live information and controls to tablets and/or smartphones

- Carryover of all Integrator Pro features including:

-

- Recipe recall

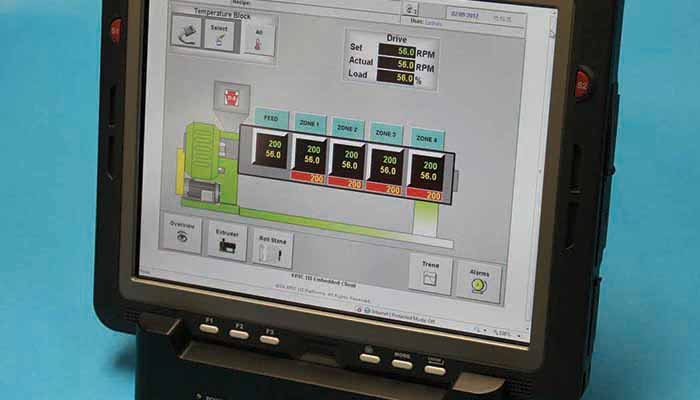

- Temperature, pressure, and drive controls

- Custom reporting

- Multi-zone tension and splice tracking for winder and unwind

- Material handling and blending interface

- Dyer interface and control

- Line drive functionality

-

This innovative control system combines total line control and data monitoring into one multi-functional information center. It is specifically designed for high-level converting processes encompassing cast film, blown film, extrusion coating, solvent and aqueous coating and drying. The features are many!

- Provides access to all machine functions including the temperature controller, PLC, and line drives interfaces

- Supervisory control that integrates all converting machine line components into a single user-friendly operator interface, connecting:

Unwinds

Winders

Coaters and dryers

Extruders

Laminators and cast sections

Water recirculation systems

Resin feed and blenders

Web guides

Treaters

Gauges - Graphics based, operator-friendly touch-screen interface with the keyboard to see the entire process at a glance

- Line run interlocks and diagnostics clearly identified to help the operator get the line running quicker

- Historical data tracking and alarm event logging help in troubleshooting product quality and uniformity problems, as well as tracking machine performance (Provides the operator with a single location to quickly locate and identify a machine or process problem.)

- Recipe management for a large number of line setup parameters to be stored and reused for quick and easy start-ups and product changeovers

- Process reports and screen prints that allow accurate documentation

- Multiple languages option for access to the language of choice by pressing a button

- System security and system backup keep the equipment up and running

- System networking

- Multiple systems networked on one line

- Multiple lines networked in one plant

- Multiple plants networked around the world

- Data available anywhere.

- Standard PC computer hardware, designed for Microsoft®

Windows® XP and - Wonderware software engine

- Phone line and/or Internet access

This control system offers a highly functional, easy-to-use, single point control and data center for converting applications. It is also the direct replacement for the Egan CMR system. As with the CMR, it includes a drives control interface, temperature control and gauge control. Advantages of the Integrator include:

Recipe management

Historical data trending

Alarms

Other upgrades for this system include:

Drives upgrades: For drive systems older than 12 to 15 years we offer:

- A DC drives upgrade with re-use of existing motors.

- New AC drives and motors for greater long-term savings.

Controls Upgrade: For machine lines with PLC’s older than 15 to 20 years we offer:

- PLC upgrades to increase machine performance and minimize downtime.

- More features and functionalities to provide a better control of the process.

The DS5 is Davis-Standard’s secure service support system. It offers comprehensive customer service using a safe and secure high-speed Internet connection. (Note: It is the customer's responsibility to provide the high-speed Internet connection.)

Advantages include:

- Faster response time to customer needs

- Faster access time to diagnose and fix problems

- Ability of Davis-Standard service personnel to connect to customer equipment from anywhere in the world

- Safe and secure connection (only authorized users have system access)

- Cost savings by avoiding lengthy downtimes

We offer several options to expand your current controls system. These include:

- Downtime tracking and production monitoring

- Company-wide telephone and messaging system

- Real-time relational database for the factory

- Basic tools to assist in organizing and presenting substantial production data

- Connections to link multiple machines, office computers and plants together

- Capabilities to view real-time production data from any computer, anywhere in the world using a standard Web browser

- Automatic die control system

- Resin feed system with gravimetric capability

ITALYCS® (Integrated Temperature And Layer Yield Control System) was first designed for blown film line control by blown film specialists in the 1980’s. Since then, continuous improvement of hardware and software combined with relentless focus on effective operation of multi-layer blown film lines have resulted in today’s Version 5. Operate and control complex 11-layer lines, as easily as a monolayer line.

- Simple, logical menu-driven interface

- Remote operator station near the bubble for fine-tuning or trouble-shooting process

- monitor, control, and repeatably change over all your vital process parameters

- Microsoft SQL Server is used to store alarms, process values, setpoints and more for one year – timestamped data records give full traceability

Robust technology with a modern design:

- Distributed IO over Ethernet/IP - drive and device upgrades are easier to implement

- Allen-Bradley ControlLogix PLC and Point IO

- HMI runs on rugged industrial PC from Siemens – third-party software (e.g. gauge measurement) can be integrated

- 19” Siemens Industrial Touch Screen for all user inputs – keyboard & mouse also included and fully supported

- A suite of responsive HMI apps programmed in C#

Main and Remote Stations are standard – run or monitor the line either from the floor or from near the bubble, with full redundancy

Want to learn more? Click to Contact us.