Recent News

Past News

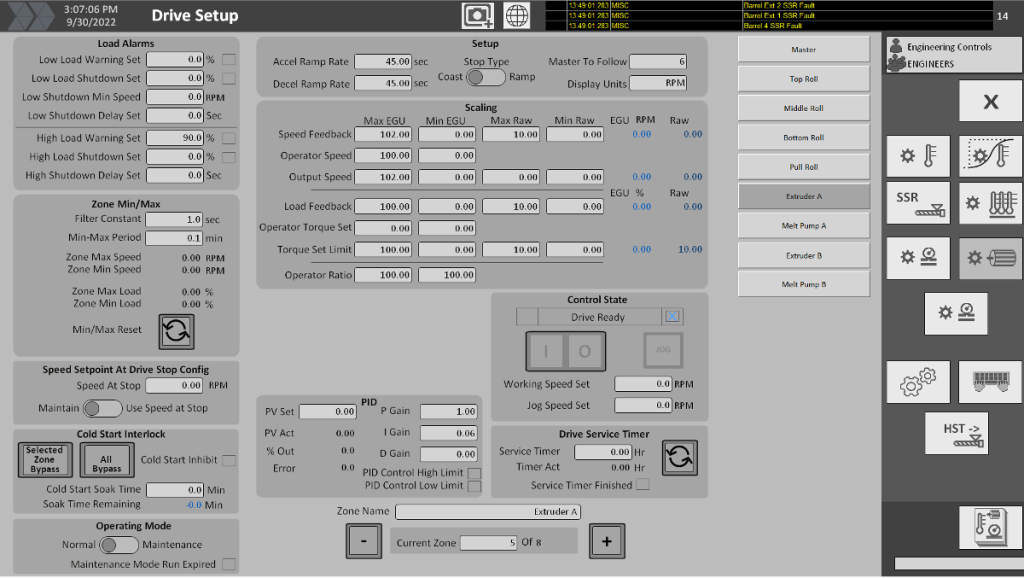

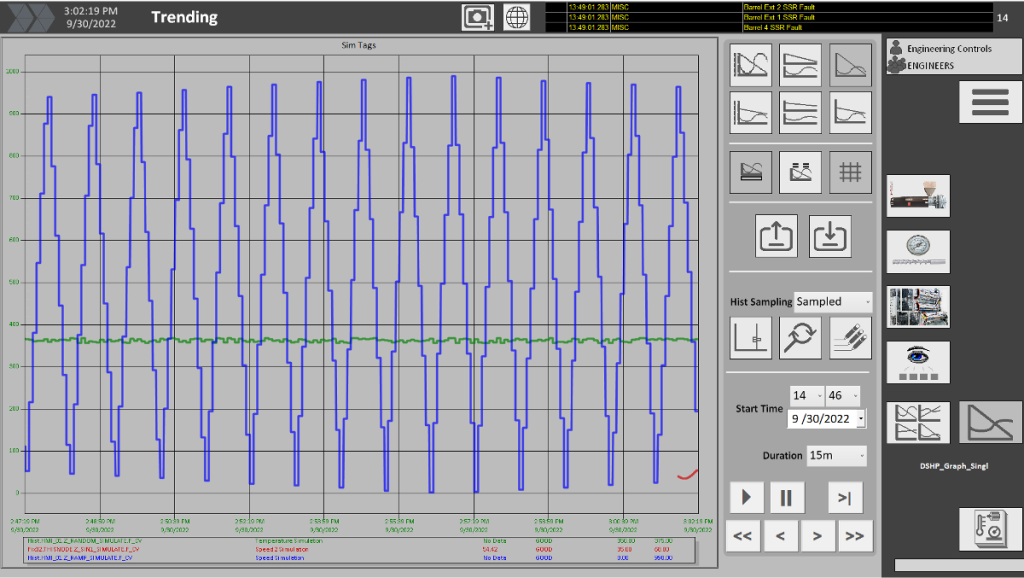

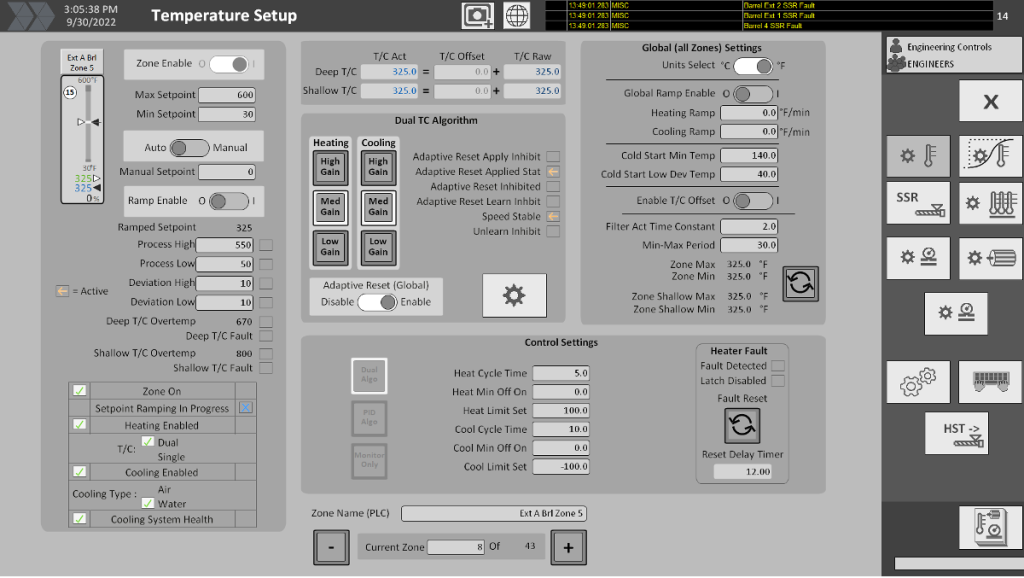

The next generation of Davis-Standard’s supervisory control technology is here – introducing the EPIC IV®. This control system builds upon the comprehensive, user-friendly approach of the EPIC III® while enhancing the operator’s experience and adding connectivity to Davis-Standard’s cloud-based solution, DS Activ-Check™. Advantages include improved graphics and symbols, additional diagnostic and efficiency tools, and screens focused on active functions and alerts.

“The EPIC IV® uses a high-performance HMI approach to strengthen the operator’s experience,” said John Clemens, Davis-Standard’s Director of Extrusion Controls. “The new color scheme focuses operator attention on active functions and alerts while also assisting operators with color vision deficiency by using shapes to indicate machine status. Overall, this will be a better supervisory control package for global installations moving forward.”

The updates seen in EPIC IV® reflect customer feedback and a commitment to digital transformation via DS Activ-Check™. The “smart” technology of DS Activ-Check™ enables real-time predictive maintenance by providing early notifications of potential machine failures. As a result, operators are alerted to issues before they happen, reducing unplanned downtime and collecting valuable data in sync with EPIC IV® control features. Users receive notifications via e-mail or text, and continuous monitoring of production machine status is available on smart devices and remote PCs. Key parameters monitored include extruder reducer, lubrication system, motor characteristics, drive power unit, barrel heating and cooling functions.

The EPIC IV® will replace the EPIC III® as the standard offering for supervisory control on all new Davis-Standard extruders. It will also be available as an upgrade for existing EPIC supervisory control systems.

For more information about the new EPIC IV® or to request a quote, contact us today.

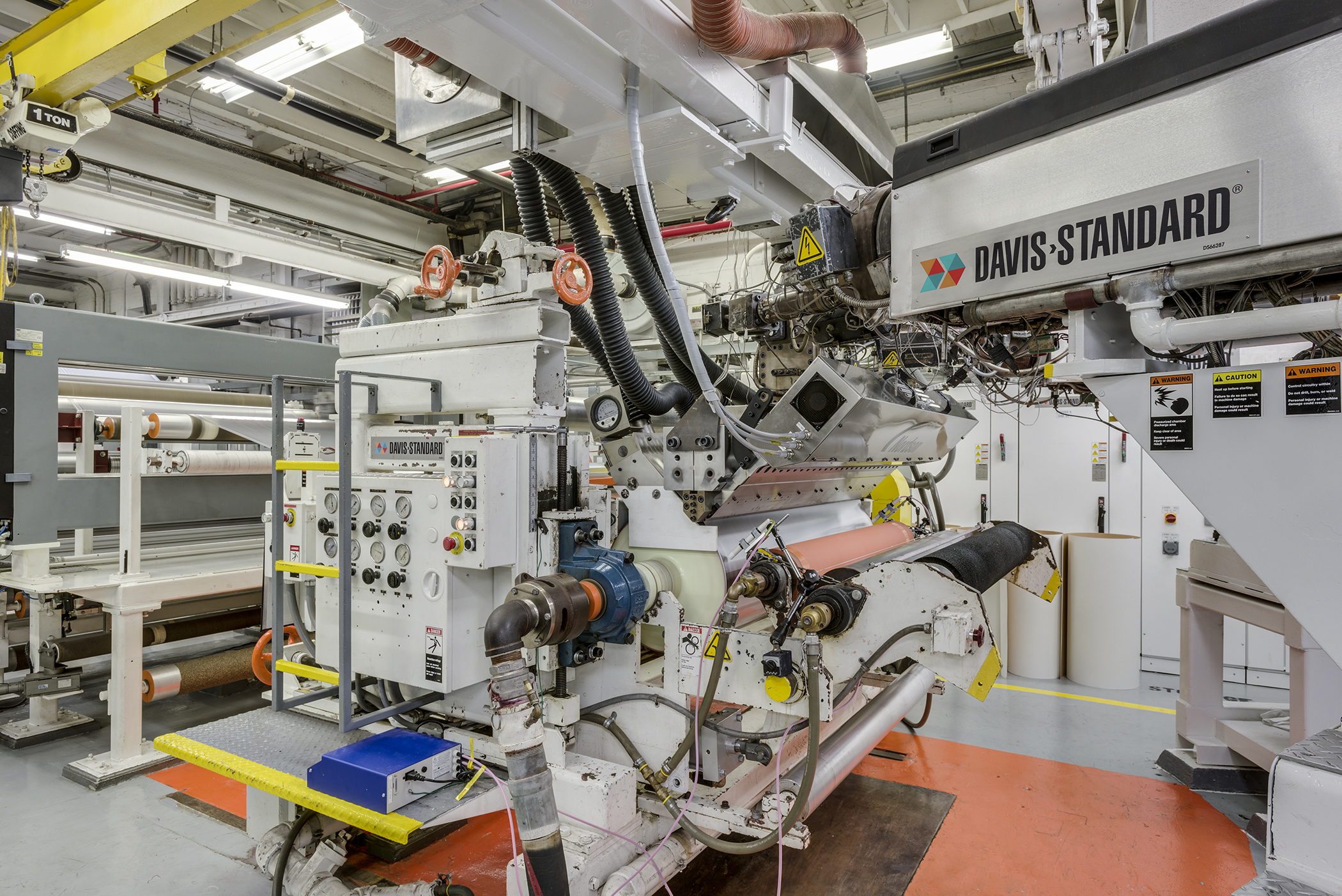

Successful innovation requires strategic teamwork. For weather seal manufacturer, Coda Products, Inc. of Epping, N.H., partnering with Davis-Standard on process development and machinery integration helped turn a brilliant idea into a superior product line. Operational since 2019, Coda Products is quickly emerging as a weatherseal leader among window and door OEMs in the U.S. and Canada. The company manufactures standard and custom seal geometries using proprietary foam technology to provide high-performance weatherseal solutions to the window and door industry.

Successful innovation requires strategic teamwork. For weather seal manufacturer, Coda Products, Inc. of Epping, N.H., partnering with Davis-Standard on process development and machinery integration helped turn a brilliant idea into a superior product line. Operational since 2019, Coda Products is quickly emerging as a weatherseal leader among window and door OEMs in the U.S. and Canada. The company manufactures standard and custom seal geometries using proprietary foam technology to provide high-performance weatherseal solutions to the window and door industry.

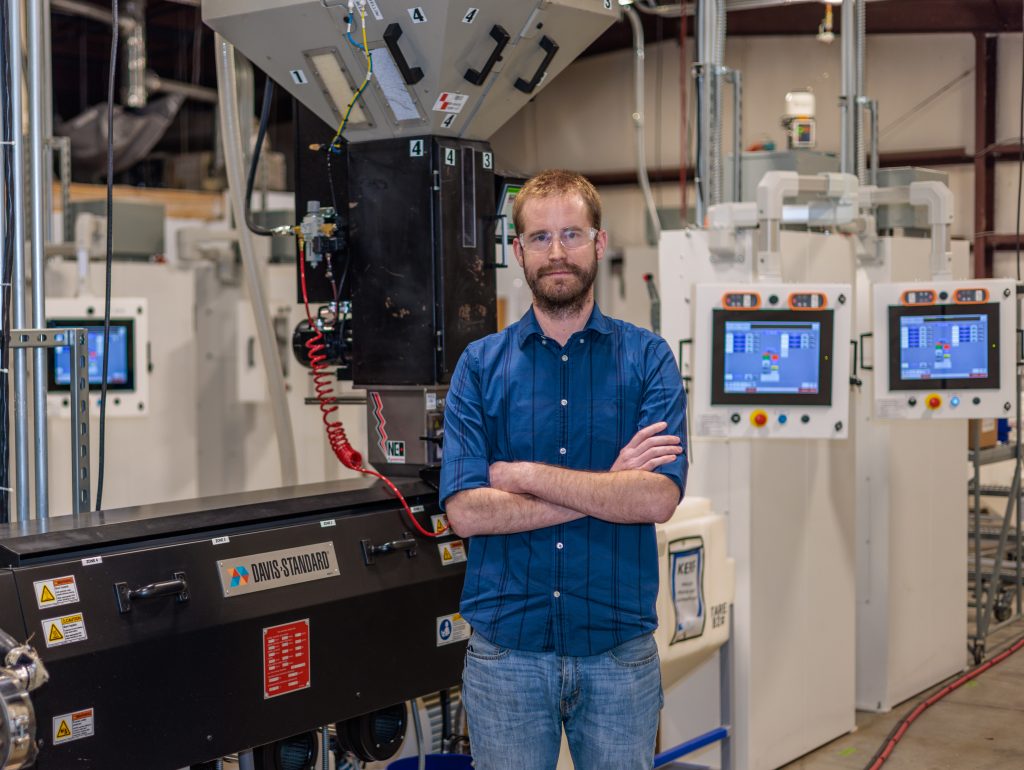

“I had experience with equipment and service from Davis-Standard prior to establishing Coda. I knew they would be an excellent team to work with as we developed our innovative production processes,” said Dan Cook, President and founder of Coda Products. “Using the lab line at Davis-Standard’s R&D facility in Pawcatuck enabled us to run product trials in order to determine the optimal machinery configuration prior to equipment purchase. Their team helped us with feedscrew design, extruder specification, and control systems for seamless integration with our proprietary in-house downstream equipment.

Installation was smooth and the service has been great. We are excited to now have significant capacity to continue our growth.”

Cook made product samples at Davis-Standard’s lab using rigorous test criteria. Once proven, he purchased several Davis-Standard extruders equipped with state-of-the-art DS-eTPC controls, specifically engineered for Coda’s processes. The proprietary production processes to make the foam used in Coda’s weatherstripping has a smaller cell structure than competitive products. This structure improves compression set performance and is augmented by a flexible skin coating and rigid carrier component for added seal strength and improved longevity. The process is designed to enable Coda to quickly develop custom profile geometries to suit customer’s needs.

“Our production technology, quality, and focused customer service has been well-received by the industry, and we’ve ramped up production in short order,” said Cook. “We are pleased with extruder performance and glad we opted for the DS-eTPC controls. This has allowed us to load and save recipes from production runs, making start-up and shutdown a breeze.”

According to Larry Giammarco, regional sales manager for Davis-Standard, Cook has always been an innovator. “I have known Dan for several years and it has been a pleasure to work with him on this exciting venture. We are committed to providing responsive service and look forward to working with Coda Products in the years to come.”

For more information about Coda Products, visit www.coda-products.com.

For more information about Davis-Standard foam solutions, visit our webpage.

Do you have a question or inquiry? Contact us today.

Davis-Standard is pleased to announce the appointment of Anthony Toklo as Chief Marketing Officer. In his new role, Tony will assume global responsibility for Davis-Standard’s marketing, communications, and branding initiatives.

Davis-Standard is pleased to announce the appointment of Anthony Toklo as Chief Marketing Officer. In his new role, Tony will assume global responsibility for Davis-Standard’s marketing, communications, and branding initiatives.

Tony comes to Davis-Standard from ITW where he led go-to-market strategy for the company’s packaging business. Prior to that, he was a product marketing manager at GE, responsible for the development and execution of business- and product-level strategic plans and market positions. He holds degrees in both mechanical and chemical engineering, as well as an MBA from Miami University.

“Tony’s technical and commercial background coupled with more than 20 years of experience make him uniquely qualified for this position,” said Giovanni Spitale, Davis-Standard CEO. “His industry knowledge, leadership ability, and success in implementing market growth strategies will be advantageous to our organization. We are pleased to have him on our senior leadership team.”

Have a question or inquiry? Please email marketing.

The electric atmosphere of K 2022 resounded at Davis-Standard’s exhibit with meaningful customer interactions, hundreds of quality leads, and multiple customer orders! Davis-Standard’s team reported a high level of excitement throughout the show, with customers arriving to discuss new projects, industry trends, and active participation in Davis-Standard’s live demonstrations of new technology, such as DS Activ-Check™ and the EDI® Prodigi die.

“This K show was exceptional in terms of foot traffic, customer engagement, and the synergy among our Davis-Standard team from different locations,” said Giovanni Spitale, Davis-Standard‘s President and CEO. “The opportunity to engage meaningfully and in person with so many of our customers was simply wonderful. We are thrilled and humbled to participate in this year’s K show in such a big way.”

Davis-Standard’s team reported significant interest in equipment for composite and micro-duct tubing lines for heating and plumbing, EV battery tempering pipes and hoses, greater automation for irrigation lines, sheet for EPET and multi-layer processes, and BOPP films, among others. Customers were focused on solutions that boost efficiency, improve recyclability, increase production capacity, and align automation and digitalization with personnel availability and capabilities. The DS Activ-Check™ cloud-based solution for preventative maintenance and process optimization was well received along with the Davis-Standard systems integration of the EDI® Prodigi die, providing more response and automatic profile control for cast film, sheet, and extrusion coating applications. Davis-Standard’s aftermarket services to improve processing and profitability were also a hot topic of conversation during the show.

According to the K 2022 website, more than 3,000 exhibitors and 176,000 trade visitors representing 157 nations participated. Visitors gave the show top marks for mapping the entire supply chain, with 98 percent saying they fully achieved the goals associated with their visit. The site noted investment intentions for equipment and equipment used in recycling and processing stood out at 43 percent. Participants were especially interested in solutions that support sustainability, the circular economy, and energy/resource efficiency in production. About 40 percent of respondents said they were investigating the topic of decarbonization.

“We are grateful to everyone who came by our exhibit during the show,” added Spitale. “It was good to see you. We appreciate your current and potential business and look forward to serving you.”

Davis-Standard is pleased to announce the systems integration of the EDI® Prodigi™ die system, a more responsive APC (automatic profile control) die for cast film, sheet and extrusion coating applications. The die, which was tested and proven at Davis-Standard’s lab in Fulton, N.Y., is three to five times faster than previous heated die bolt-type systems. The new APC uses a direct motorized bolt adjustment for instant modification versus slower responding heaters used in current thermal bolt models.

Davis-Standard is pleased to announce the systems integration of the EDI® Prodigi™ die system, a more responsive APC (automatic profile control) die for cast film, sheet and extrusion coating applications. The die, which was tested and proven at Davis-Standard’s lab in Fulton, N.Y., is three to five times faster than previous heated die bolt-type systems. The new APC uses a direct motorized bolt adjustment for instant modification versus slower responding heaters used in current thermal bolt models.

“The Prodigi™die, when integrated with Davis-Standard’s control system, is able to achieve APC control specification in a few minutes compared to more than 10 minutes when using a heated die bolt, depending on the situation. We look forward to demonstrating these results to the industry and integrating the Prodigi™ die into our machinery portfolio,” said Rick Keller, Davis-Standard’s Vice President of Market Development for Converting Systems. “Being the process control system integrator of EDI/Nordson in this endeavor as well as other vendors for major developments enables us to deliver value-added technology to our customers.”

Click here to inquire about the Prodigi™ die today!

Davis-Standard is pleased to announce the systems integration of the EDI® Prodigi™ die system, a more responsive APC (automatic profile control) die for cast film, sheet and extrusion coating applications. The die, which was tested and proven at Davis-Standard’s lab in Fulton, N.Y., is three to five times faster than previous heated die bolt-type systems. The new APC uses a direct motorized bolt adjustment for instant modification versus slower responding heaters used in current thermal bolt models.

“The Prodigi™die, when integrated with Davis-Standard’s control system, is able to achieve APC control specification in a few minutes compared to more than 10 minutes when using a heated die bolt, depending on the situation. We look forward to demonstrating these results to the industry and integrating the Prodigi™ die into our machinery portfolio,” said Rick Keller, Davis-Standard’s Vice President of Market Development for Converting Systems. “Being the process control system integrator of EDI/Nordson in this endeavor as well as other vendors for major developments enables us to deliver value-added technology to our customers.”

For inquiries on the Prodigi™die, click here.

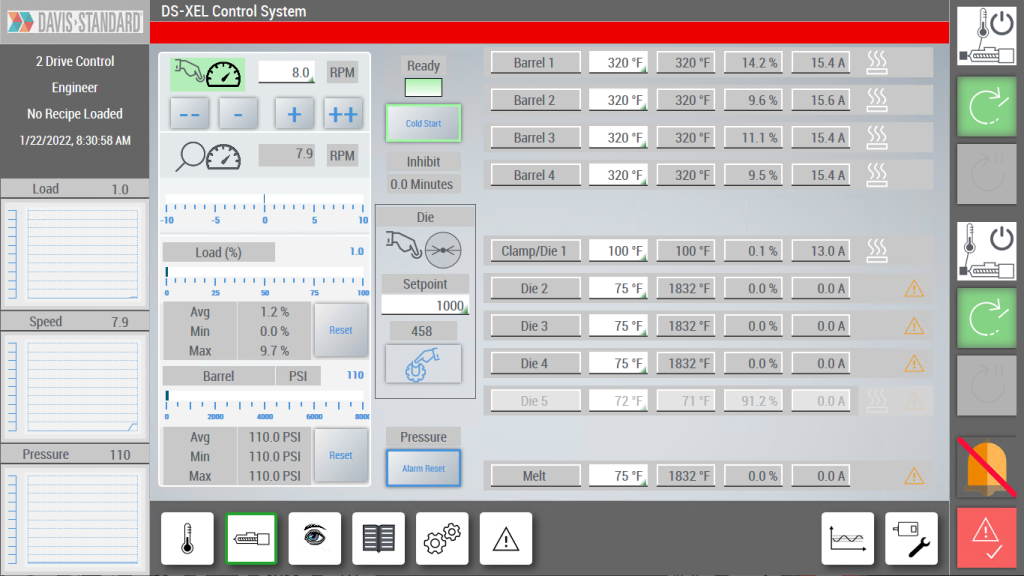

Davis-Standard is pleased to announce the release of its DS-XEL control system. This system, which replaces mature discrete controls, implements high-performance HMI features to better facilitate the data and process information requirements of today’s manufacturing environment. Attention is given to active functions for a better operator experience and improved connectivity. The DS-XEL will be the new standard control for Davis-Standard’s Super Blue® and HPE extruder lines and is compatible with the DS Activ-Check™ cloud-based platform. It is also available as an upgrade to existing extruder controls.

“This controller merges the latest PLC and HMI offerings to enable an operator-friendly package with greater attention to detail,” said John Clemens, Davis-Standard’s Director of Extrusion Controls. “It also incorporates key features only available with larger system controllers for troubleshooting and process improvement.”

The DS-XEL provides on-screen graphic trending of essential extruder parameters, visually tracking temperature, barrel pressure, motor speed and motor load. Speed deviation from the setpoint is displayed along with extruder maintenance run timer and heater zone alarms, indicating deviation, process temperature, power failure, heater load and sensor break. The minimum, maximum, and average motor load is captured during each production run. Recipe creation and storage allows for repeatability of multiple products on the same line.

Other advantages include process alarm logging, real-time and historical data trending, auto and self-tuning of heat zones for quick die changes, and an on-screen display of individual zone heaters. In addition, the DS-XEL addresses connectivity requirements with a simple connection to ERP/MRP or upper-level supervisory control using a standard OPC-UA interface.

For more information about the DS-XEL or to get a quote, contact us here.

For Vesta Thermoplastics, a Lubrizol Life Science Health (LLS Health) Company, extruding the impossible is a daily endeavor. However, Davis-Standard’s extruders have risen to the challenge. Vesta, a leading supplier of tight-tolerance extrusions for the medical industry, recently installed a Davis-Standard MEDD extruder to augment the company’s existing Davis-Standard HPE extruders. The MEDD has helped Vesta increase productivity, alleviate potential backlogs and address shorter lead times for the company’s diverse portfolio of thin-wall tubing, multi-lumen, and coextrusion products. This includes tubing and devices that support single-use and long-term implantable applications such as neurostimulation, feeding and drainage tubes, catheters, and vascular loops.

“We’ve had a lot of success with our HPE extruders, and the MEDD has been a welcomed addition. We bought this machine during 2022 MD&M West since the show is only 30 minutes from our facility, making delivery very convenient,” explained Steven Mayol, Senior Process Engineer at Vesta Thermoplastics. “Installation went smoothly and the MEDD is already proving to be a good investment. Being able to exchange barrel sizes when necessary and having the capacity to run a variety of high-temperature polymers is essential to our business model. We pride ourselves in delivering extrusion tubing that no one can challenge, including extrusions that involve new polymers.”

The MEDD’s interchangeable barrel assembly, ease of maintenance, and operator accessibility have been notable for Vesta. This design is specific to clean room environments, providing a replaceable feed section liner and direct drive technology for bottom line efficiency and materials flexibility. Stainless steel surfaces, quick change capabilities, and a broad polymer range enable the tubing consistency and reliable performance Vesta needs to serve current and emerging medical markets. Vesta’s innovation encompasses lead tubing, balloon tubing, custom extrusion, PEEK extrusion, braided tubing, striping and multi-layer coextrusion, multi-lumen, heat shrink tubing, rapid and bump extrusion.

Mayol also appreciates Davis-Standard’s personalized approach to service. “Davis-Standard has been exemplary with timely, customer-centric service. Their troubleshooting support has also been helpful whenever we’ve needed it,” he said. “This includes designing the right feedscrews for our polymer range to address targeted outputs with excellent melt quality and product consistency.”

For more information about Vesta’s capabilities as part of LLS Health, visit here.

For more information about Davis-Standard’s MEDD and HPE extruders, visit our page here.

Have questions or if you would like to inquire about machinery solutions to fit your operational needs?

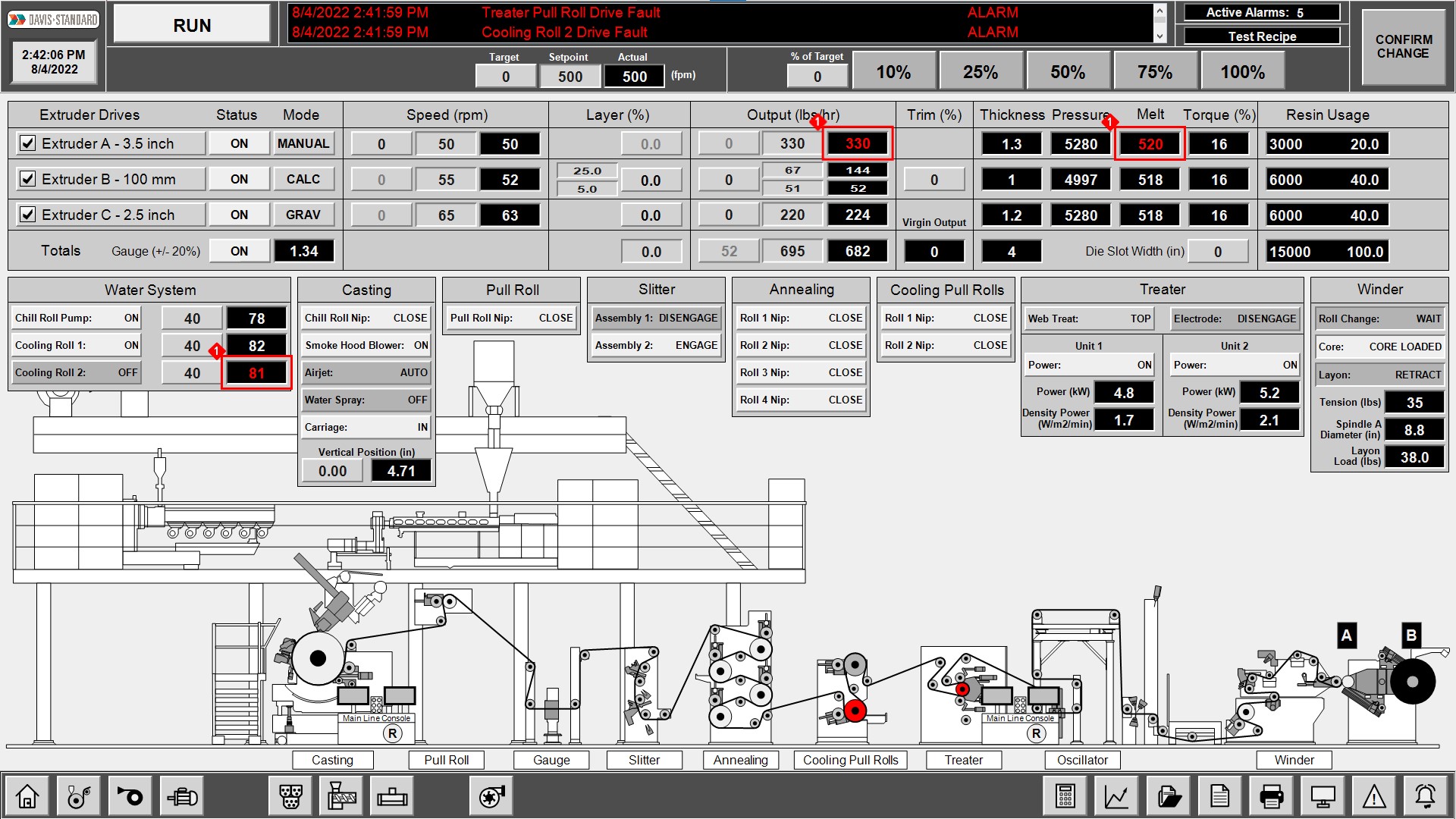

Davis-Standard is pleased to announce the release of its Integrator PRO+™ control upgrade for cast film, extrusion coating, and aqueous coating processes. This system is the successor to Davis-Standard’s existing Integrator PRO™ human-machine interface (HMI) and supports the DS Activ-Check™ digital transformation platform, which offers a robust suite of analytical tools, cloud and local data storage options, process and equipment technology algorithms. Control upgrades are an integral part of Davis-Standard’s aftermarket services to ensure customers have access to the latest technology.

The Integrator PRO+™ delivers all the valued features of the previous version, such as recipe recall, intuitive interface and control functions, custom reporting and line drive functionality, while further facilitating user-friendliness, mobility, and process efficiency outcomes. Improvements include central control of all production parameters, process data analysis to assist with overall equipment effectiveness (OEE), and compatibility with obsolete controls installed on legacy Davis-Standard machinery. In addition, processors can take advantage of extra data storage, in-depth troubleshooting and analysis, and situational awareness services for seamless portability of live information and controls to tablets and smartphones.

Processors upgrading to the Integrator PRO+™ will appreciate better overall line control, greater connectivity, and ease of use. Operators benefit from better graphics, streamlined displays of the most relevant process information, and a visual safety overview screen illustrating the status of each embedded safety device to aid in diagnostics and troubleshooting. In addition, the Integrator PRO+™ doubles data storage compared to the Integrator PRO, with process data collection and trending screens also doubled.

“The Integrator PRO+™ is a logical next step in helping our converting customers take advantage of Industry 4.0 solutions that contribute to bottom-line factors such as improved sustainability, product quality, machinery efficiency and project team mobility,” said Sumeet Kumar, Davis-Standard’s Director of Strategic Marketing for Converting Systems. “We look forward to seeing customers gain value from this control option, especially when combined with our DS Activ-Check™ solution.”

To find out more about the Integrator PRO+™, or to inquire about an upgrade, contact us here or call 860-407-3969. You can also learn more here.

Davis-Standard is pleased to announce the formation of a global sustainability initiative that prioritizes resource conservation and supports circular economy initiatives, social responsibility, and business collaboration. As a company, Davis-Standard is accelerating efforts to cultivate best practices and machinery innovation that aligns with United Nations (UN) sustainable development goals.

“We have a collective responsibility to provide technology that enables forward-thinking solutions to complex challenges such as food security, reliable energy sources, and strategic infrastructure,” said Giovanni Spitale, Davis-Standard CEO. “We have prioritized sustainability efforts along with safety, quality, and productivity to address the needs of our customers while playing an active role ourselves. As a result, we have already made significant advances in our machinery development regarding reduced waste, energy efficiency, and increased recyclability. We look forward to doing more as we work toward a sustainable future.“

Davis-Standard has committed to the following objectives by the year 2025:

- Direct R&D funding, targeting five percent of sales revenue, toward sustainable equipment development. Efforts will focus on further expanding customer use of recycled content, reducing material waste, and efficient use of energy and process structures to support the circular economy.

- Increase procurement of carbon pollution-free electricity to 100 percent of Davis-Standard’s total energy usage.

- Host “Davis-Standard Community Days” to support every community in which Davis-Standard is located. Each facility will identify and complete two environmentally-conscious activities per year.

- Achieve ISO 14001 certification at all of our global facilities.

For more information about Davis-Standard’s sustainability initiative, visit our site here.

Davis-Standard is pleased to announce that Raje Dwaraka has been appointed Chief Financial Officer (CFO). In her new role, Dwaraka will lead Davis-Standard’s finance team and partner with business unit leaders. She will also be instrumental in designing and executing the company strategy.

Davis-Standard is pleased to announce that Raje Dwaraka has been appointed Chief Financial Officer (CFO). In her new role, Dwaraka will lead Davis-Standard’s finance team and partner with business unit leaders. She will also be instrumental in designing and executing the company strategy.

Raje is a talented financial leader, and we are thrilled to have her as part of our executive leadership team,” said Giovanni Spitale, Davis-Standard’s Chief Executive Officer. “She brings a proven track record of leading global teams, delivering sound financial strategy, and close partnership with business leadership – all of which will be key to continuing the growth trajectory that we are on”.

Dwaraka comes to Davis-Standard from NielsenIQ, where she was Chief Accounting Officer (CAO), leading a global team of 900 employees in 80 countries. Prior to that role, she was CFO of the $2 billion Food Services business unit within Pactiv, where she oversaw finance and strategic planning and played a key role in listing the company on NASDAQ (Ticker: PTVE). She also held the positions of Head of SEC Reporting and Controller during her time in the company. Raje obtained her CPA license from the Illinois Board of Public Accountants and also holds a Chartered Accounting (CA) degree from India.

Have questions or would like to make an inquiry? Please contact us here.