Recent News

Past News

Medical product manufacturing is a tough job; persistent timelines, exacting quality standards, equipment performance, tighter margins, and staffing shortages are just a few things piled on the plate. So how to make your job easier? The answer lies in reliable technology and the forward-thinking potential of digital transformation. Digitalization and “smart factory” technology may already be integrated into the operation. If you are still researching the possibilities, here are some insights to help take the next step.

Medical product manufacturing is a tough job; persistent timelines, exacting quality standards, equipment performance, tighter margins, and staffing shortages are just a few things piled on the plate. So how to make your job easier? The answer lies in reliable technology and the forward-thinking potential of digital transformation. Digitalization and “smart factory” technology may already be integrated into the operation. If you are still researching the possibilities, here are some insights to help take the next step.

To read the full article, click here.

Stongington, CT government website posted the below news brief on behalf of the Beautification Committee of Stongington. Earth Day was a huge success for Davis-Standard as we had several volunteers committed to our sustainability goals for our customers, company, environment, and community. Thank you to all that participated!

Stongington, CT government website posted the below news brief on behalf of the Beautification Committee of Stongington. Earth Day was a huge success for Davis-Standard as we had several volunteers committed to our sustainability goals for our customers, company, environment, and community. Thank you to all that participated!

"Partnership makes it possible! This Spring the Town has made major strides forward, planting nearly 150 trees, thanks to efforts from the Stonington Beautification Committee, Department of Public Works, our Tree Warden, First Selectman, and many additional donors, volunteers and additional town and school departments who make these special community projects possible.

Trees provide cooling and clean our air, they store carbon, capture stormwater, reduce energy costs and species loss. They not only improve physical health, but mental health as well. Approximately 200 trees have been lost in recent years due to a variety of factors including disease, age or storm damage. It has been with all of this in mind, that Stonington has been focusing efforts on increasing its tree canopy around the community this Spring.

The Beautification Committee aligned with community partners this past Earth Day and Arbor Day, including Davis Standard employees, the First Selectman and Stonington High School students, to plant over 100 trees saplings in Spellman Park and at a Stonington Water Pollution Control Authority property. In addition to planting trees, volunteers also took part in a town-wide clean-up, collecting tons of garbage that could have ended up in on our streams and rivers. The committee has also been working to add more pollinating plants to many of our memorials and parks across Stonington. And they continue to come up with plans for the Fall and following Spring."

To read more and view Beautification Committee photos of volunteers, click here.

As the head of Davis-Standard, Giovanni Spitale has an unusual background.

As the head of Davis-Standard, Giovanni Spitale has an unusual background.

Unlike many executives who work their way up in the plastics industry, the U.S. Navy Nuclear Power School graduate spent much of his time in the aerospace industry.

“That’s the first of many unorthodox things you're going to discover about me today,” Spitale told Plastics Machinery & Manufacturing Senior Staff Reporter Bruce Geiselman during a recent interview.

He also might be the only industry CEO who once ran a nuclear reactor aboard a U.S. aircraft carrier as a nuclear power plant supervisor, serving aboard the USS Abraham Lincoln.

After the Navy, he worked at companies including Honeywell and GE Aviation. Between 2019 and 2022, Spitale served as VP of commercial parts within Boeing Global Services, where had responsibility for profit-and-loss management and the strategic direction of the company’s $4 billion portfolio of commercial aircraft and engine parts businesses.

His experience in the aviation industry helped prepared him to lead Davis-Standard, said Spitale, who has been president of the extrusion machinery maker since February 2022.

To view the full interview, visit the PMM website: click here.

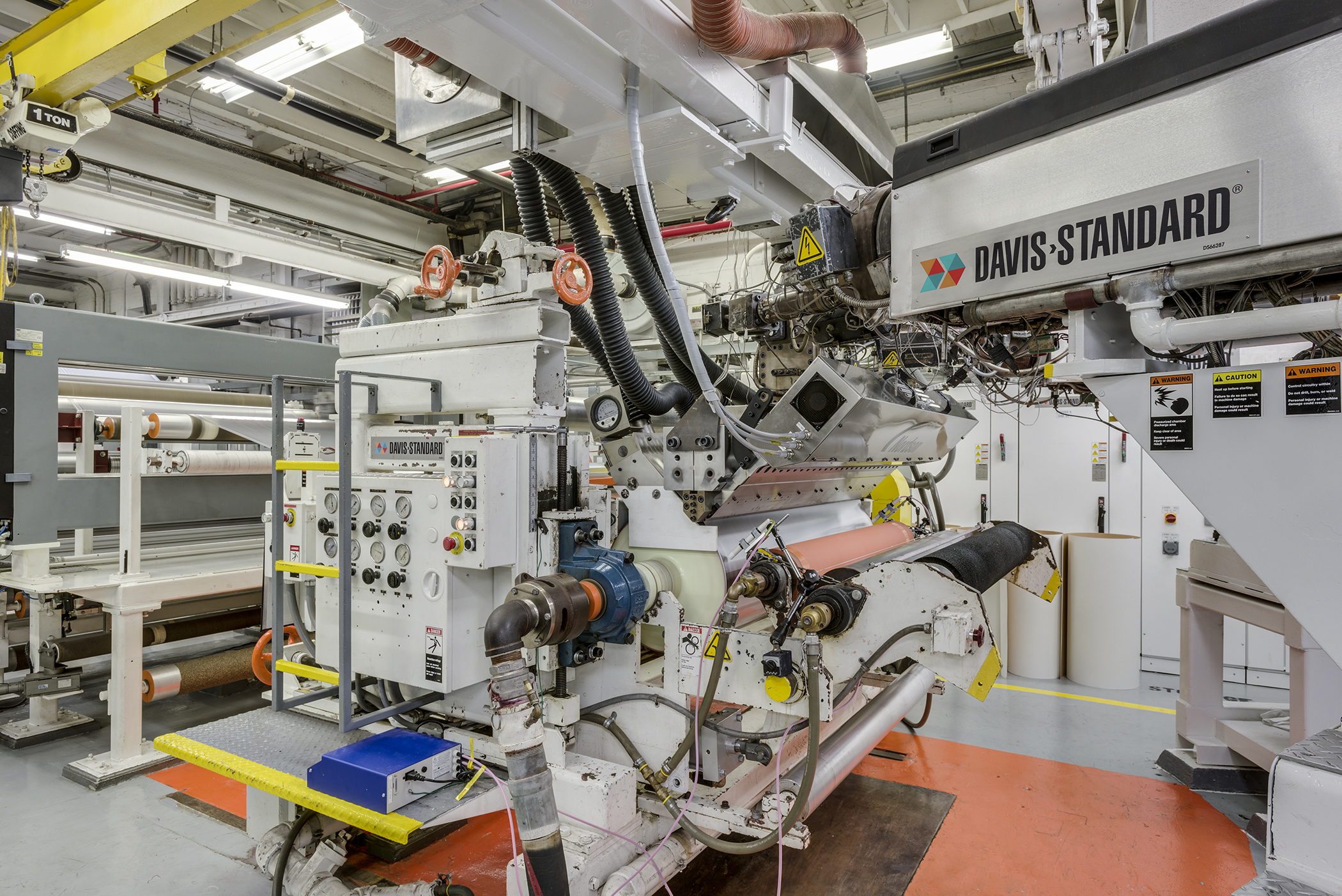

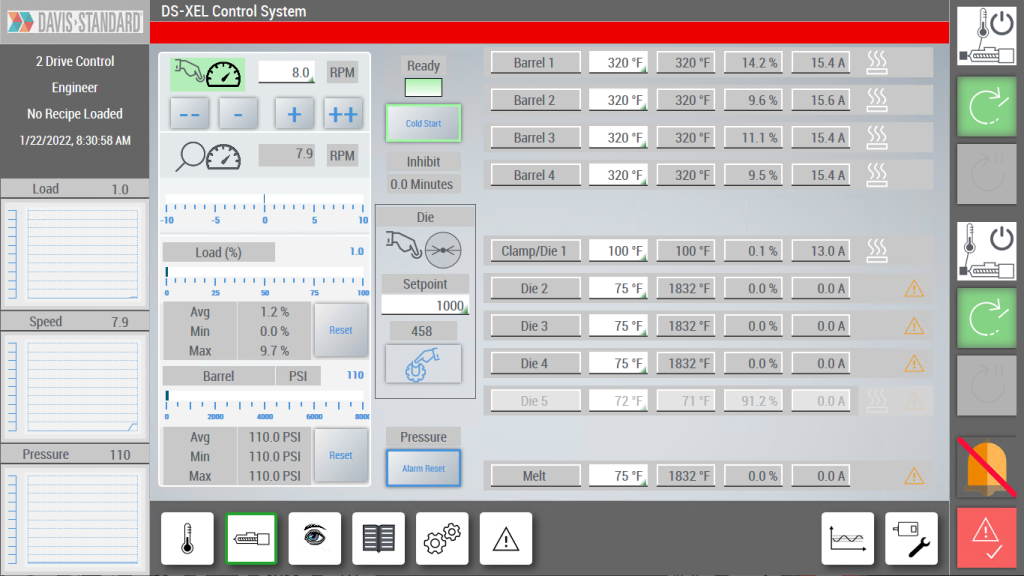

Davis-Standard’s medical extrusion expertise and customer-centric approach will be promoted during MD&M West 2023 at booth 3911, February 7-9, in Anaheim, Calif. Show visitors will have an opportunity to view a running polycarbonate pipette line equipped with a Davis-Standard HPE (high performance) extruder and new DS-XEL process control. The line will also feature downstream equipment from the Conair Group and an OD/ID/Wall gauge system by Zumbach Electronics, both Davis-Standard technology partners. In addition, a 2.5-inch (50mm) Davis-Standard Super Blue® extruder will be displayed with DS-XEL controls, and customers can learn more about the company’s DS Activ-Check™ cloud-based platform for preventative maintenance and monitoring.

Davis-Standard’s medical extrusion expertise and customer-centric approach will be promoted during MD&M West 2023 at booth 3911, February 7-9, in Anaheim, Calif. Show visitors will have an opportunity to view a running polycarbonate pipette line equipped with a Davis-Standard HPE (high performance) extruder and new DS-XEL process control. The line will also feature downstream equipment from the Conair Group and an OD/ID/Wall gauge system by Zumbach Electronics, both Davis-Standard technology partners. In addition, a 2.5-inch (50mm) Davis-Standard Super Blue® extruder will be displayed with DS-XEL controls, and customers can learn more about the company’s DS Activ-Check™ cloud-based platform for preventative maintenance and monitoring.

The DS-XEL, introduced last fall, implements high-performance HMI features to better facilitate the data acquisition and process information required for today’s manufacturing. Processors benefit from built-in security to prevent unauthorized changes to system set-up parameters, multi-language support, process alarm logging, and real-time and historical data trending. In addition, visual attention is given to active functions for a better operator experience and improved connectivity. The DS-XEL is the new standard control for Davis-Standard’s Super Blue® and HPE extruders.

Davis-Standard’s HPE extruder will power the line. This extruder is available in an adjustable vertical or horizontal configuration in sizes ranging from ¾-inch (19mm) to 1 ¾ inches (44mm). A direct coupled motor and smaller footprint make this machine ideal for tight manufacturing spaces and clean-room environments. The HPE can be run as the primary extruder, or as a complementary extruder in a coextrusion arrangement.

The Super Blue® is easy-to-maintain, energy-efficient, and provides increased torque capacity for high-viscosity resins. It is available in sizes from 2 inches (50mm) to 4 1/2 inches (114mm) with a range of DSB® barrier screw designs and a three-year warranty.

“We continue to expand upon our medical tubing solutions targeted at energy efficiency, sustainable practices, and process versatility to address evolving resin and end-product requirements,” said Kevin Dipollino, Davis-Standard’s Senior Product Manager of Pipe, Profile and Tubing Systems. “We have had excellent feedback on the DS-XEL, and can engineer this system to accommodate our DS Activ-Check™ digital transformation tool in order to achieve overall equipment effectiveness (OEE).”

DS Activ-Check™ is gaining traction as a smart manufacturing solution due to its many advantages, such as real-time monitoring, predictive and preventative maintenance, process and equipment analytics, and multi-faceted team connectivity. Processors can apply DS Activ-Check™ to amplify production efficiency, easily connect and collaborate using smart devices and remote PCs, manage cloud-based data collection, improve operator productivity and safety, and accelerate service and support.

Davis-Standard provides multiple services aimed at strengthening product line performance. This includes die reconditioning, feedscrew replacement to boost outputs and material homogeneity, control system upgrades to enhance digitalization and product changeover, and more! Feasibility studies are available for existing lines to address outputs, resin changes, product development, and more. An extensive spare parts inventory and regional vendor network help minimize supply chain delays.

“Consistent product quality, sustainable manufacturing, and reduced waste directly impact the bottom line,” added Dipollino. “Whether it’s’ medical tubing, medical packaging, materials for hygienic products, or other markets, we seek to deliver value-added equipment technology and timely aftermarket services to each of our customers.”

Davis-Standard representatives at the show will include Kevin Dipollino, Justin McKenna, and Dr. Jason Baird. For more information about the show, visit www.mdmwest.com.

Click here to schedule an appointment with one of our representatives at the show!

Learn more about Davis-Standard's Pipe and Tube capabilities here.

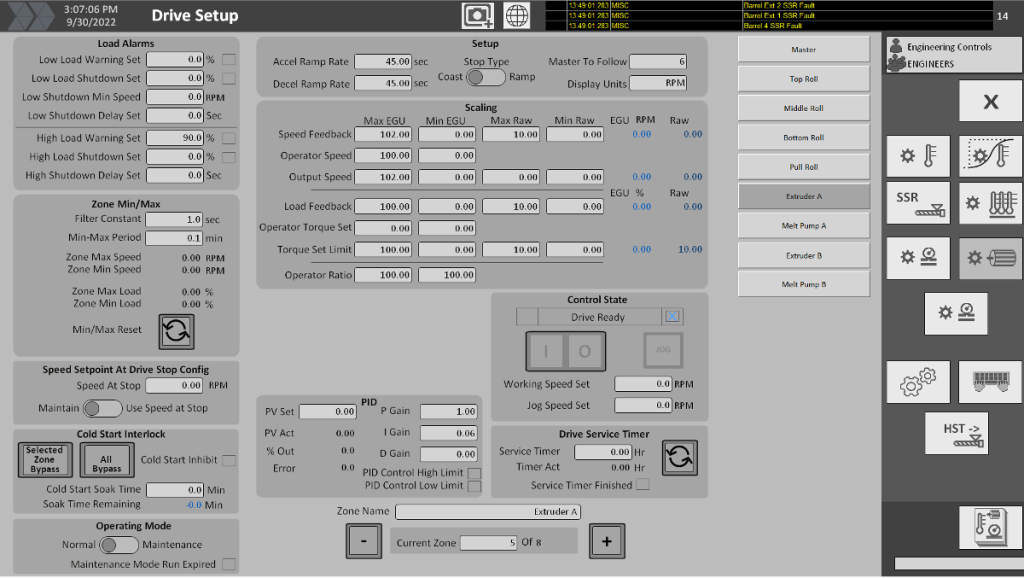

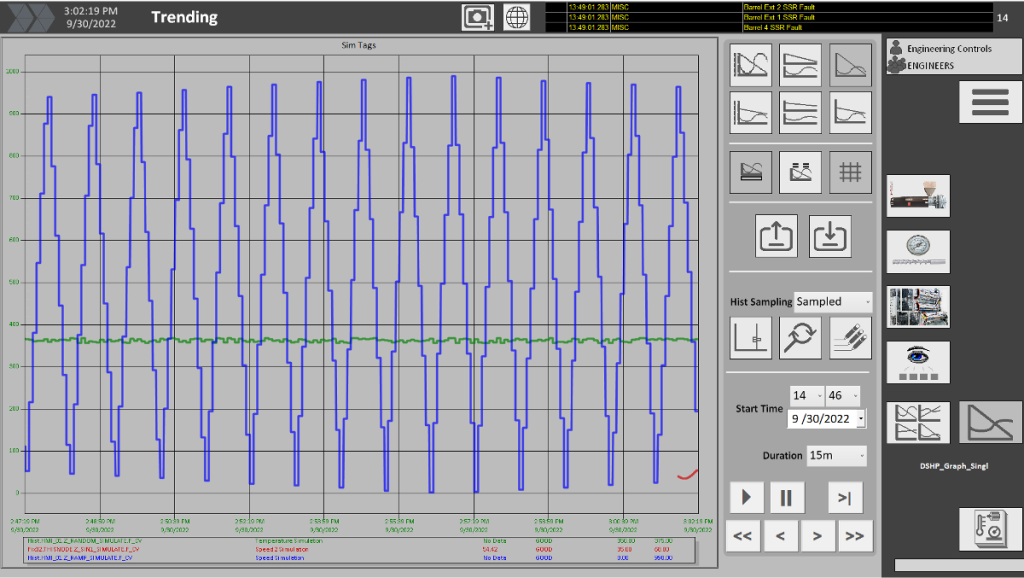

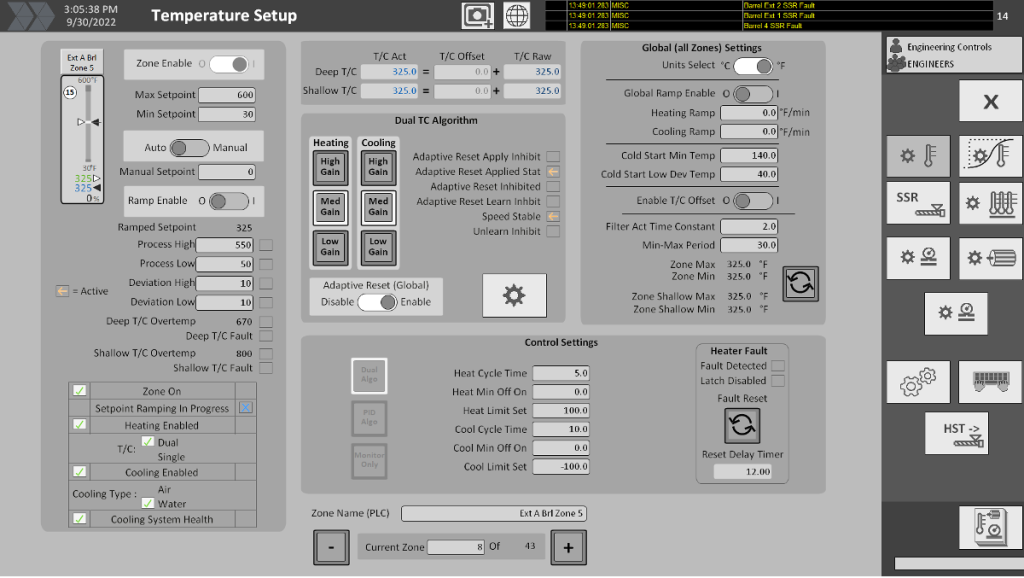

The next generation of Davis-Standard’s supervisory control technology is here – introducing the EPIC IV®. This control system builds upon the comprehensive, user-friendly approach of the EPIC III® while enhancing the operator’s experience and adding connectivity to Davis-Standard’s cloud-based solution, DS Activ-Check™. Advantages include improved graphics and symbols, additional diagnostic and efficiency tools, and screens focused on active functions and alerts.

“The EPIC IV® uses a high-performance HMI approach to strengthen the operator’s experience,” said John Clemens, Davis-Standard’s Director of Extrusion Controls. “The new color scheme focuses operator attention on active functions and alerts while also assisting operators with color vision deficiency by using shapes to indicate machine status. Overall, this will be a better supervisory control package for global installations moving forward.”

The updates seen in EPIC IV® reflect customer feedback and a commitment to digital transformation via DS Activ-Check™. The “smart” technology of DS Activ-Check™ enables real-time predictive maintenance by providing early notifications of potential machine failures. As a result, operators are alerted to issues before they happen, reducing unplanned downtime and collecting valuable data in sync with EPIC IV® control features. Users receive notifications via e-mail or text, and continuous monitoring of production machine status is available on smart devices and remote PCs. Key parameters monitored include extruder reducer, lubrication system, motor characteristics, drive power unit, barrel heating and cooling functions.

The EPIC IV® will replace the EPIC III® as the standard offering for supervisory control on all new Davis-Standard extruders. It will also be available as an upgrade for existing EPIC supervisory control systems.

For more information about the new EPIC IV® or to request a quote, contact us today.

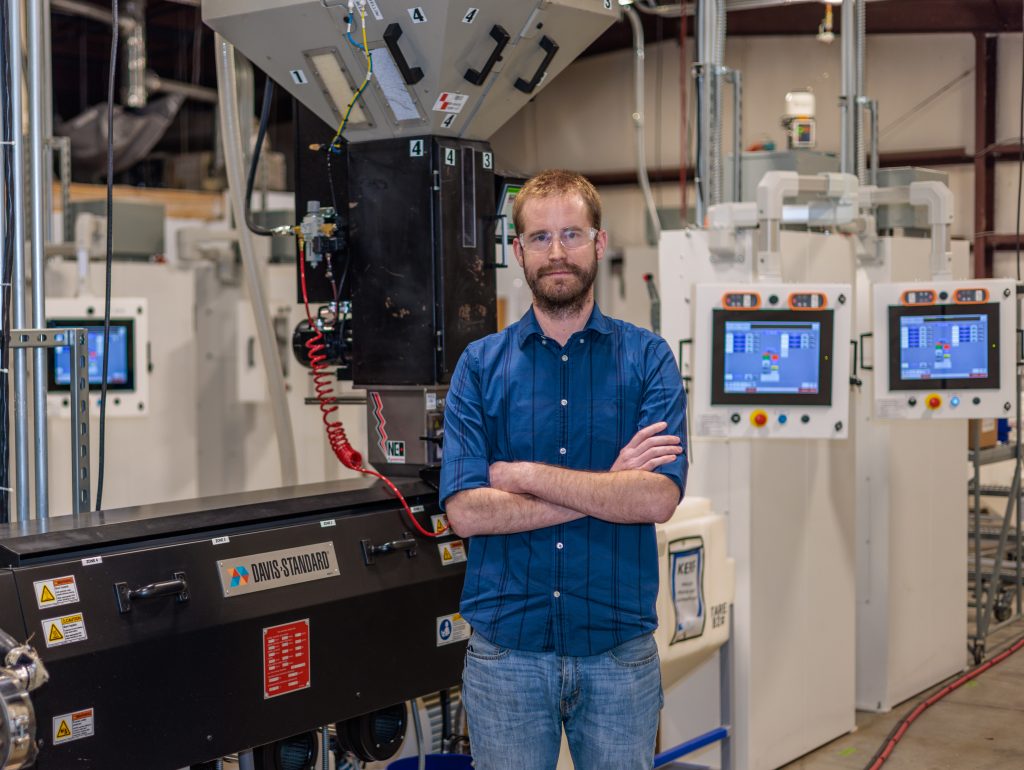

Successful innovation requires strategic teamwork. For weather seal manufacturer, Coda Products, Inc. of Epping, N.H., partnering with Davis-Standard on process development and machinery integration helped turn a brilliant idea into a superior product line. Operational since 2019, Coda Products is quickly emerging as a weatherseal leader among window and door OEMs in the U.S. and Canada. The company manufactures standard and custom seal geometries using proprietary foam technology to provide high-performance weatherseal solutions to the window and door industry.

Successful innovation requires strategic teamwork. For weather seal manufacturer, Coda Products, Inc. of Epping, N.H., partnering with Davis-Standard on process development and machinery integration helped turn a brilliant idea into a superior product line. Operational since 2019, Coda Products is quickly emerging as a weatherseal leader among window and door OEMs in the U.S. and Canada. The company manufactures standard and custom seal geometries using proprietary foam technology to provide high-performance weatherseal solutions to the window and door industry.

“I had experience with equipment and service from Davis-Standard prior to establishing Coda. I knew they would be an excellent team to work with as we developed our innovative production processes,” said Dan Cook, President and founder of Coda Products. “Using the lab line at Davis-Standard’s R&D facility in Pawcatuck enabled us to run product trials in order to determine the optimal machinery configuration prior to equipment purchase. Their team helped us with feedscrew design, extruder specification, and control systems for seamless integration with our proprietary in-house downstream equipment.

Installation was smooth and the service has been great. We are excited to now have significant capacity to continue our growth.”

Cook made product samples at Davis-Standard’s lab using rigorous test criteria. Once proven, he purchased several Davis-Standard extruders equipped with state-of-the-art DS-eTPC controls, specifically engineered for Coda’s processes. The proprietary production processes to make the foam used in Coda’s weatherstripping has a smaller cell structure than competitive products. This structure improves compression set performance and is augmented by a flexible skin coating and rigid carrier component for added seal strength and improved longevity. The process is designed to enable Coda to quickly develop custom profile geometries to suit customer’s needs.

“Our production technology, quality, and focused customer service has been well-received by the industry, and we’ve ramped up production in short order,” said Cook. “We are pleased with extruder performance and glad we opted for the DS-eTPC controls. This has allowed us to load and save recipes from production runs, making start-up and shutdown a breeze.”

According to Larry Giammarco, regional sales manager for Davis-Standard, Cook has always been an innovator. “I have known Dan for several years and it has been a pleasure to work with him on this exciting venture. We are committed to providing responsive service and look forward to working with Coda Products in the years to come.”

For more information about Coda Products, visit www.coda-products.com.

For more information about Davis-Standard foam solutions, visit our webpage.

Do you have a question or inquiry? Contact us today.

Davis-Standard is pleased to announce the appointment of Anthony Toklo as Chief Marketing Officer. In his new role, Tony will assume global responsibility for Davis-Standard’s marketing, communications, and branding initiatives.

Davis-Standard is pleased to announce the appointment of Anthony Toklo as Chief Marketing Officer. In his new role, Tony will assume global responsibility for Davis-Standard’s marketing, communications, and branding initiatives.

Tony comes to Davis-Standard from ITW where he led go-to-market strategy for the company’s packaging business. Prior to that, he was a product marketing manager at GE, responsible for the development and execution of business- and product-level strategic plans and market positions. He holds degrees in both mechanical and chemical engineering, as well as an MBA from Miami University.

“Tony’s technical and commercial background coupled with more than 20 years of experience make him uniquely qualified for this position,” said Giovanni Spitale, Davis-Standard CEO. “His industry knowledge, leadership ability, and success in implementing market growth strategies will be advantageous to our organization. We are pleased to have him on our senior leadership team.”

Have a question or inquiry? Please email marketing.

The electric atmosphere of K 2022 resounded at Davis-Standard’s exhibit with meaningful customer interactions, hundreds of quality leads, and multiple customer orders! Davis-Standard’s team reported a high level of excitement throughout the show, with customers arriving to discuss new projects, industry trends, and active participation in Davis-Standard’s live demonstrations of new technology, such as DS Activ-Check™ and the EDI® Prodigi die.

“This K show was exceptional in terms of foot traffic, customer engagement, and the synergy among our Davis-Standard team from different locations,” said Giovanni Spitale, Davis-Standard‘s President and CEO. “The opportunity to engage meaningfully and in person with so many of our customers was simply wonderful. We are thrilled and humbled to participate in this year’s K show in such a big way.”

Davis-Standard’s team reported significant interest in equipment for composite and micro-duct tubing lines for heating and plumbing, EV battery tempering pipes and hoses, greater automation for irrigation lines, sheet for EPET and multi-layer processes, and BOPP films, among others. Customers were focused on solutions that boost efficiency, improve recyclability, increase production capacity, and align automation and digitalization with personnel availability and capabilities. The DS Activ-Check™ cloud-based solution for preventative maintenance and process optimization was well received along with the Davis-Standard systems integration of the EDI® Prodigi die, providing more response and automatic profile control for cast film, sheet, and extrusion coating applications. Davis-Standard’s aftermarket services to improve processing and profitability were also a hot topic of conversation during the show.

According to the K 2022 website, more than 3,000 exhibitors and 176,000 trade visitors representing 157 nations participated. Visitors gave the show top marks for mapping the entire supply chain, with 98 percent saying they fully achieved the goals associated with their visit. The site noted investment intentions for equipment and equipment used in recycling and processing stood out at 43 percent. Participants were especially interested in solutions that support sustainability, the circular economy, and energy/resource efficiency in production. About 40 percent of respondents said they were investigating the topic of decarbonization.

“We are grateful to everyone who came by our exhibit during the show,” added Spitale. “It was good to see you. We appreciate your current and potential business and look forward to serving you.”

Davis-Standard is pleased to announce the systems integration of the EDI® Prodigi™ die system, a more responsive APC (automatic profile control) die for cast film, sheet and extrusion coating applications. The die, which was tested and proven at Davis-Standard’s lab in Fulton, N.Y., is three to five times faster than previous heated die bolt-type systems. The new APC uses a direct motorized bolt adjustment for instant modification versus slower responding heaters used in current thermal bolt models.

Davis-Standard is pleased to announce the systems integration of the EDI® Prodigi™ die system, a more responsive APC (automatic profile control) die for cast film, sheet and extrusion coating applications. The die, which was tested and proven at Davis-Standard’s lab in Fulton, N.Y., is three to five times faster than previous heated die bolt-type systems. The new APC uses a direct motorized bolt adjustment for instant modification versus slower responding heaters used in current thermal bolt models.

“The Prodigi™die, when integrated with Davis-Standard’s control system, is able to achieve APC control specification in a few minutes compared to more than 10 minutes when using a heated die bolt, depending on the situation. We look forward to demonstrating these results to the industry and integrating the Prodigi™ die into our machinery portfolio,” said Rick Keller, Davis-Standard’s Vice President of Market Development for Converting Systems. “Being the process control system integrator of EDI/Nordson in this endeavor as well as other vendors for major developments enables us to deliver value-added technology to our customers.”

Click here to inquire about the Prodigi™ die today!

Davis-Standard is pleased to announce the systems integration of the EDI® Prodigi™ die system, a more responsive APC (automatic profile control) die for cast film, sheet and extrusion coating applications. The die, which was tested and proven at Davis-Standard’s lab in Fulton, N.Y., is three to five times faster than previous heated die bolt-type systems. The new APC uses a direct motorized bolt adjustment for instant modification versus slower responding heaters used in current thermal bolt models.

“The Prodigi™die, when integrated with Davis-Standard’s control system, is able to achieve APC control specification in a few minutes compared to more than 10 minutes when using a heated die bolt, depending on the situation. We look forward to demonstrating these results to the industry and integrating the Prodigi™ die into our machinery portfolio,” said Rick Keller, Davis-Standard’s Vice President of Market Development for Converting Systems. “Being the process control system integrator of EDI/Nordson in this endeavor as well as other vendors for major developments enables us to deliver value-added technology to our customers.”

For inquiries on the Prodigi™die, click here.

Davis-Standard is pleased to announce the release of its DS-XEL control system. This system, which replaces mature discrete controls, implements high-performance HMI features to better facilitate the data and process information requirements of today’s manufacturing environment. Attention is given to active functions for a better operator experience and improved connectivity. The DS-XEL will be the new standard control for Davis-Standard’s Super Blue® and HPE extruder lines and is compatible with the DS Activ-Check™ cloud-based platform. It is also available as an upgrade to existing extruder controls.

“This controller merges the latest PLC and HMI offerings to enable an operator-friendly package with greater attention to detail,” said John Clemens, Davis-Standard’s Director of Extrusion Controls. “It also incorporates key features only available with larger system controllers for troubleshooting and process improvement.”

The DS-XEL provides on-screen graphic trending of essential extruder parameters, visually tracking temperature, barrel pressure, motor speed and motor load. Speed deviation from the setpoint is displayed along with extruder maintenance run timer and heater zone alarms, indicating deviation, process temperature, power failure, heater load and sensor break. The minimum, maximum, and average motor load is captured during each production run. Recipe creation and storage allows for repeatability of multiple products on the same line.

Other advantages include process alarm logging, real-time and historical data trending, auto and self-tuning of heat zones for quick die changes, and an on-screen display of individual zone heaters. In addition, the DS-XEL addresses connectivity requirements with a simple connection to ERP/MRP or upper-level supervisory control using a standard OPC-UA interface.

For more information about the DS-XEL or to get a quote, contact us here.