Recent News

Past News

Davis-Standard will promote a broad portfolio of technology solutions August 24-25, 2020, at Lambeau Field Atrium in Green Bay, Wisc., in booth 93. Davis-Standard will highlight standard and tailored liquid coating lines for window and paint protection, specialty products, PSA and silicone release liners, as well as their inline and offline unwind and winding options for diverse applications. The complementary portfolio of Deacro Industries, acquired by Davis-Standard last year, will also be promoted. Deacro will be promoting their slitting, rewinding and web handling capabilities for a range of flexible packaging applications in booth 17.

Davis-Standard’s liquid coating lines are designed for uniform coat weights with technology for quick change and reduced waste. The cartridge coater enables quick web width change-over, a fast-sleeve change system without breaking the web, feature auto trim start and increased productivity. Unwinds are built with a reliable high-speed splice for reduced waste, stub roll capability and to minimize tail length.

Winders feature stationary knife transfer for high-speed transfers and reduced fold-over waste. Control systems reduce “dial-in” time and include process monitoring and troubleshooting to assist with performance. Davis-Standard is also able to retrofit existing lines to improve performance.

Davis-Standard collaborates with customers to offer standard and custom liquid coating options to serve global film and flexible packaging, construction, automotive and medical converting markets. The company also offers comprehensive product development in their state-of-the-art technology solutions centers as well as 24/7 after-sales support and service.

For more information about liquid coating equipment options prior to the show, visit https://davisstandard.com/converting_system/liquid-coating/. For Deacro Industries, visit https://www.deacro.com/.

In response to increased demand for aseptic packaging technology for emerging markets, Davis-Standard has introduced the dsX™ Aseptic 400 triplex extrusion coating and laminating line. This best-in-class solution offers quick changes, waste reduction and precision web handling for maximum widths of 1,350mm (53 inches) and speeds from 250 to 400 mpm (820 to 1,312 fpm). It is designed for paper, aluminum foils and/or films used in aseptic and liquid carton board packaging products.

“We have sold aseptic lines with similar outputs in the past, but based on market analysis, there was a need for a dedicated product line for emerging markets,” said, Michael Schröder, Head of Sales EMEA and Product Management at Davis-Standard’s German subsidiary ER-WE-PA GmbH. “The dsX Aseptic 400 is pre-engineered to provide optimum specifications for emerging market customers in terms of output and technology for process efficiency.”

Davis-Standard is the global market leader in extrusion lamination lines for aseptic packaging products. This line configuration reflects that leadership with customization options to address diverse structures, including those used for aseptic and fresh milk/beverage filling machines. According to Michael Schröder, another advantage is Davis-Standard’s regional after-sale service and support, and more than 100 global references for similar applications.

“One of the most significant benefits to customers in emerging markets is knowing they are getting value for first-rate technology and service, which is based on experience,” he said. “Each component on this line is designed for performance and efficiency, and we have the global resources to support them.”

For more information about films and flexible packaging equipment options, visit https://davis-standard.com/flex-packaging-films.

Photo caption: The dsX™ Aseptic 400 triplex extrusion coating and laminating line is engineered for emerging markets.

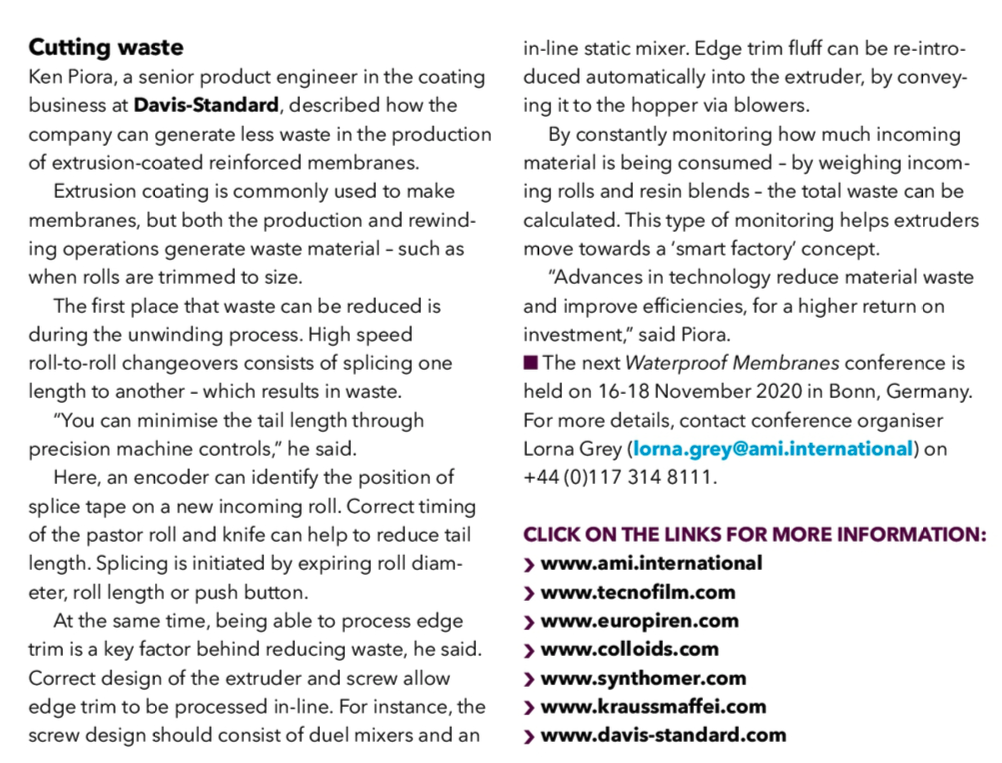

Check out the latest article by Davis-Standard's Senior Product Engineer Ken Piora

Read the full article here

The protective properties of packaging used for medical, healthcare and food products have proven especially valuable during the COVID-19 pandemic. As converters have ramped up production, the necessity of quality processes and equipment to maintain packaging integrity while boosting outputs has been paramount. Davis-Standard’s flexible packaging solutions are not only built for reliable outputs, quick changes and minimal waste, but are proven in terms of rigorous technical and business demands. Single-source responsibility from unwind to winder, an operator-friendly platform, and a global network have enabled Davis-Standard to help customers improve processes while offsetting costs in a high margin business.

The protective properties of packaging used for medical, healthcare and food products have proven especially valuable during the COVID-19 pandemic. As converters have ramped up production, the necessity of quality processes and equipment to maintain packaging integrity while boosting outputs has been paramount. Davis-Standard’s flexible packaging solutions are not only built for reliable outputs, quick changes and minimal waste, but are proven in terms of rigorous technical and business demands. Single-source responsibility from unwind to winder, an operator-friendly platform, and a global network have enabled Davis-Standard to help customers improve processes while offsetting costs in a high margin business.

Advantages of Davis-Standard’s flexible packaging solutions can be found in each line component. Unwinds are engineered with a high-speed splice for reduced waste, stub roll capability and to minimize tail length. Extruder packages offer gauge control and uniformity while allowing flexibility with extruder configuration and screw design. Coaters and laminators support seamless and expedient change-overs, excellent adhesion properties, as well as auto-trim start for safety. Winders feature stationary knife transfer for high-speed transfers and reduced fold-over waste. Control systems reduce “dial-in” time and offer process monitoring and troubleshooting to assist with performance. Recipe storage, integrated control for third party equipment, custom drive control, pressure and gauging systems, trending and diagnostics analysis add to efficiency. All technology is backed by Davis-Standard’s customer service available 24 hours a day, seven days a week, as well as vast global resources.

Davis-Standard is also available to support customers with R&D and new product development. For more information about flexible packaging equipment options, visit https://davis-standard.com/flex-packaging-films.

Photo caption: Davis-Standard’s flexible packaging lines are engineered for reliable outputs, quick changes and minimal waste.

ER-WE-PA GmbH, Davis-Standard’s German subsidiary, recently installed a custom five-roller calender unit for a global adhesive tape manufacturer. Designed to customer specifications at our recently ISO-9001-2015 certified ER-WE-PA facility in Erkrath, this machine features a unique design to accommodate layer thickness precision, reproducibility, processing flexibility and operator accessibility. ER-WE-PA is supporting converting customers by engineering innovative solutions for a wide range of applications, says Michael Krämer, Managing Director of ER-WE-PA. “Specifically for this customer, we took proven technology and customized various components to address sensitive adhesive processes. Even when subjected to significant shear forces, this machine is equipped to consistently control gap size within the micron range during production. The customer is very pleased with the performance in terms of increased capacity of current products and the potential for future growth.”

The calender unit is capable of supporting a variety of materials including foams, fabrics, PET or MOPP, or coated products using five different application techniques. The calender rolls are individually adjustable in longitudinal and transverse directions, and the machine design enables a quick exchange of each pair of rolls. This makes it possible to process variable layer thicknesses with different viscosities. All essential machine functions and process parameters are automatically controlled.

For more information about ER-WE-PA’s capabilities or Davis-Standard’s, visit https://davis-standard.com/flex-packaging-films/.

Photo Caption: Five-roller calender unit capable of supporting a variety of materials including foams, fabrics, PET or MOPP, or coated products.

Airlite Plastics Company has expanded production capabilities at its plant in Nazareth, Pennsylvania with a semi-custom Davis-Standard sheet line. The new line, installed in 2019, supports Airlite’s thin-gauge sheet production for products of various thicknesses and textures. This includes proprietary Orthoform® sheet used in fabricating orthotics and prosthetics, the primary market supported by the company’s Pennsylvania Division. Davis-Standard engineered the line for strict repeatability, gauge control, product consistency and low scrap, which are essential to Airlite’s highly controlled processes. Airlite operates five sheet lines at the plant, all from Davis-Standard brand companies, to support customers from the U.S. and Canada, as well as a growing international clientele.

“Davis-Standard’s equipment has performed really well for us and that is part of the reason we are a return customer. The thing that influenced us the most is the service from Davis-Standard’s team,” said Tony Alfieri, vice president and general manager of the Pennsylvania Division, Airlite Plastics Company. “From the initial quote request through the manufacturing process and start-up, to aftersale service and support, we always get a great response. The new line is being used for our Orthoform® products and some other customized work we do in thermoforming, die-cutting, printing and lamination applications.”

Alfieri said the right equipment combination is important because thin-gauge sheet production is challenging. His plant schedules operations around processing a unique mix of sheet thicknesses from 0.16 to .25 inches (4 to 6mm), and with different textures ranging from smooth to haircell. For example, the sheet used for Orthoform® is drape-formed using a very specific resin. The ability to manufacture this type of sheet with reliability and accuracy is the company’s niche along with a “can do” mindset of taking on projects other extruders do not. Projects such as smaller batch custom colors, exotic resin blends, laminates and R&D are all part of Airlite’s service portfolio. As such, the design of the new Davis-Standard line reflects a collaborative effort between Davis-Standard and Alfieri’s team. Key components of the new line include a Thermatic® III extruder, DS-eVue control system, screen changer package, die, melt pump, and XP Express® PS series roll stand system with a unique roll configuration to ensure quality and consistency.

According to Steve DeAngelis, vice president of sheet, fiber, foam and reprocessing at Davis-Standard, “This line is a great example of how Davis-Standard is equipped to support customers who serve the medical industry. Since we are a single-source supplier, we have more control over every component, which is essential for ensuring customers like Airlite can depend on their investment. We are grateful for their business and wish them much success as they continue to grow their business.”

“Engineering and installing a complete sheet line is a huge undertaking with a lot of attention to detail. This project was smooth and on a tight schedule with Davis-Standard’s expertise benefitting us every step of the way,” added Alfieri. “Our customers choose us because we can fine-tune their process for repeatability. We focus on prioritizing the process and not pushing the pounds, which has been a key part of our success. Knowing we have the technology to make that happen is critical.”

For more information about Airlite Plastics, visit www.airliteplastics.com. For more information about Davis-Standard’s sheet technology, visit www.davis-standard.com/extrusion_system/sheet.

Photo Caption: Tony Alfieri with the newly installed Thermatic® III extruder and DS-eVue control system - sheet line for Orthoform® product production.

ACI Plastics, a U.S. leader in post-industrial plastics reprocessing, will install two Davis-Standard reclaim extruders at its new South Carolina plant in early 2020 with two more slated for a fourth-quarter installation in California. The extruders will be used to pelletize scrap materials from the mixed rigid plastics, including the production of PE and PP plastic pellets for resale. The expansion is part of ACI’s partnership with PreZero, a global waste management and recycling firm that invests in new technologies, systems, and processes committed to long-term environmental sustainability. With PreZero’s support, ACI Plastics will expand its footprint for closed-loop sustainable processing of film and rigid plastics to better support customers nationwide. In addition to the South Carolina plant and forthcoming California facility, ACI has operations in Arizona, Nebraska and Michigan.

“Being able to offer great products with significant environmental benefits and cost savings is increasingly important,” said Scott Melton, President of ACI Plastics. “Our process expertise combined with PreZero’s technical innovation and resources is expanding access to our services nationwide. In addition, we have been very diligent in our equipment selection. We chose Davis-Standard as our extruder provider because of a successful history that spans almost 20 years. A Davis-Standard extruder we purchased in 2000 has operated non-stop without issue.” He added, “We also appreciate the service provided by Gerry Sposato, our Davis-Standard representative, who has been very responsive in addressing both equipment engineering needs and price requirements.”

ACI offers services in size reduction, plastic separation, paint removal, compounding, blending and logistics for a range of automotive scrap materials, including technology for recycling multi-layer automotive instrument panels (IPs) and door panels. In addition to reclaimed pellets, ACI can supply pellets derived from virgin materials with a compounding capacity of over 40,000,000 pounds per year. Davis-Standard extruders are a good fit for ACI’s commitment to sustainable practices due to minimal maintenance and operating costs, and in Davis-Standard’s ability to stock and readily ship spare parts. ACI also appreciates that the extruders are manufactured domestically.

Melton said, “We anticipate adding two more Davis-Standard extruders in the fourth quarter of 2020 when the California plant is completed. The goal of PreZero to ‘reduce the waste of resources across the entire value chain to zero’ is an aspiration we are proud to be engaged in as we expand our capabilities. We are also grateful for equipment suppliers like Davis-Standard in helping us make that happen.”

For more information about ACI Plastics, visit www.aciplastics.com. For more information about PreZero, visit www.prezero.us. For more information about Davis-Standard’s reclaim capabilities, visit www.davis-standard.com/extrusion_system/reprocessing-and-compounding/.

Davis-Standard will promote its global equipment platform at Plastprintpack in Lagos, Nigeria (tradeshow postponed, date to follow) at booth H.04, hall 1. Davis-Standard’s sales representative, Dr. Anye Chifen, the managing director of ENGICCS, will be available to discuss technology and provide information for cast film, extrusion coating, liquid coating, blown film and aftermarket services. Dr. Chifen will give a presentation on converting technologies, “Functions and Applications for Flexible Packaging Laminates” (bags and pouches, barrier, extended shelf-life, laminates, lidding films, and non-food) on March 26 at 10:45 a.m.

Davis-Standard will promote its global equipment platform at Plastprintpack in Lagos, Nigeria (tradeshow postponed, date to follow) at booth H.04, hall 1. Davis-Standard’s sales representative, Dr. Anye Chifen, the managing director of ENGICCS, will be available to discuss technology and provide information for cast film, extrusion coating, liquid coating, blown film and aftermarket services. Dr. Chifen will give a presentation on converting technologies, “Functions and Applications for Flexible Packaging Laminates” (bags and pouches, barrier, extended shelf-life, laminates, lidding films, and non-food) on March 26 at 10:45 a.m.

Davis-Standard’s global equipment platform includes:

Aftermarket Capabilities – Davis-Standard’s ability to service equipment for nearly every extrusion and converting application, including non-Davis-Standard brands, is one of the company’s greatest advantages. This includes an extensive spare parts inventory, timely 24/7-customer service, global technical capabilities, and rebuild and retrofit services.

Cast Film – Davis-Standard offers a stretch film line that redefines modular efficiency for high-grade film operations. This technology is the new standard for stretch film line configurations. Advantages include a compact machine arrangement, ease of operation and servicing, excellent profile control, consistent roll quality and an intuitive control package. The system is engineered for producing thin films from 7.8 microns to 13 microns (31-to 51-gauge) at high speeds.

Winding/Unwinding – Davis-Standard’s side-by-side DS S3 winder enables maximum slit widths for hand-wrap, machine-wrap and jumbo rolls. All rolls are discharged on the downstream end of the winder and are conveyed to a common side of the line to simplify roll packing and future automation. There is an auxiliary lay-on roll to eliminate top-wind waste during transfer, optimizing roll quality and eliminating outer wrap transfer waste. There is a 30-second cycle time regardless of the number of slit widths, ideal for hand-wrap products. Specific to CPP films, Davis-Standard offers the horizontal ironing roll winder. This winder has an adjustable ironing roll which allows the converter to control the amount of air introduced into the winding roll, substantially reducing “tin canning,” a common issue when running CPP. Horizontal Winder tailored design for best-in-class-speed for thin gauge structures. Technology for inline slitting enabling reduced waste and operational automation. Davis-Standard’s recent acquisition of Deacro has augmented these equipment options with high-performance slitting, rewinding and roll handling equipment for the converting process of paper, film and foil materials.

Extrusion Coating – Davis-Standard addresses basic applications all the way up to high-speed, complex requirements. Systems are engineered for everything from high-quality flexible packaging, thermal lamination and stand-up pouches, to lidding, tube, and aseptic films. Specifications can be customized based on market requirements and investment plans.

The Davis-Standard’s dsX flex-pack™ system provides converters and package printers with a high-value, competitively-priced package. An adaptable machine configuration gives processors the flexibility to compete in a variety of emerging application markets including salted snack and noodle bags, toothpaste tubes, personal care products, condiment packs and stand-up pouches. Production benefits include product consistency, excellent bonding strength, greater uptime and productivity, and reduced waste and production costs. The economic benefit of these 1,500 fpm (450 mpm) machines is enabling many regional converters to distinguish themselves from the competition. Davis Standard is the Global standard for Aseptic lines with the highest production speed and process efficiency, tailored of line components for your needs and structure, including waste reduction with inline recycling system and energy savings with energy-efficient heater design- EEACEH. Greater uptime – quick recipe change with high automation grade and easy maintenance.

Liquid Coating – Davis-Standard’s curtain slide coater and five-roll silicone coater combine versatility with performance. The curtain slide coater applies single layer coatings at rates up to 2800 fpm (853 mpm) with expansion capabilities up to two additional layers. The five-roll silicone coater is capable of applying 100 percent silicone at rates up to 2400 fpm (732 mpm). This coater is constructed of stainless steel for ease of cleanup and includes a mist removal system. Davis-Standard supports liquid coating for slow or high-speed applications, cleanroom environments, film or paper substrates, ultra-thin and ultra-thick coatings, and precision coating and drying.

Blown Film – Davis-Standard supplies extrusion systems for applications in high-barrier food packaging, agricultural films, geomembrane, stretch film, printing and laminating films, flexible packaging, collation shrink films and stretch hooders. For films that require enhanced clarity and flexibility, Davis-Standard offers the Aquafrost® water-quench system. Other options include industry-leading Vector® air rings, DSB® feedscrew designs, and Streamlined Coextrusion Die (SCD®), Optiflow and Vertex dies, each designed to process specific films. Davis-Standard also supplies downstream and terminal equipment as well as MDO’s, oscillating haul offs, and winders to optimize web handling and output goals. These solutions can accommodate standard applications as well as complex substrates and structures requiring precise tension control to ensure quality while minimizing waste. Automation options are available to reduce cycle time and augment benefits from increased outputs.

For more information about Plastprintpack, visit www.ppp-nigeria.com; ENGICCS, visit www.engiccs.com; and Davis-Standard, visit www.davis-standard.com.

Photo caption: Davis-Standard’s DS S3 winder for hand-wrap, machine-wrap and jumbo rolls

Davis-Standard is pleased to announce that Zachary Ament has been promoted to Executive Vice President effective March 6, 2020. He will replace longtime Davis-Standard employee and team leader Ernie Plasse who is retiring. Ament has been with Davis-Standard for over seven years, most recently serving as Vice President of Business Development. In that role, he has been heavily involved in the development and tactical execution of Davis-Standard’s organizational strategy across the global organization including mergers, acquisitions, strategic agreements and more, positioning him well to assume Plasse’s role.

“Ernie’s leadership, industry knowledge and vast experience will be greatly missed,” said Jim Murphy, Davis-Standard’s President and CEO. “He’s had an extraordinary 46-year career at Davis-Standard. His humility and work ethic set an excellent example for our entire team at Davis-Standard, and we wish him all the best in retirement.” Murphy added, “Zachary will do an outstanding job in this role and has been working alongside Ernie to ensure a smooth transition. We look forward to his perspective and leadership as we continue our commitment to outstanding customer service.”

Plasse began his career as a stockroom clerk at Sterling Blow Molding, (a Davis-Standard brand) in 1973, and assumed greater roles of responsibility in the years to come, eventually becoming the vice president of manufacturing at Sterling. He relocated to Davis-Standard’s headquarters in Pawcatuck, Conn., in 1994. Plasse continued to excel in various leadership roles, leading to his current role as executive vice president – aftermarket in 2013. The entire Davis-Standard family wishes him well in retirement.

SIG is a leading system and solutions provider for aseptic packaging. The company has several locations worldwide and works in partnership with its customers to bring food and beverage products to customers in a safe, sustainable and affordable way.

Michael Schröder, Head of Sales EMEA and Product Management said, “We look forward to working collaboratively with the team at SIG to ensure their new line is equipped for the company’s current application range while allowing for new growth. Their approach of sustainable processing and quality products aligns well with our equipment objectives.”

“We are excited to partner with SIG on this extrusion coating line. Our equipment has a reputation for being best-in-class in terms of speed, quick changes and waste reduction. We are able to address their unique film structures, regulatory requirements and environmental sustainability in a manner that will give them a competitive advantage. Our global Davis-Standard network will also be valuable in terms of aftermarket support and service.”

The system is slated for installation in 2020.

For more information about Davis-Standard’s extrusion coating capabilities, please visit https://davis-standard.com/converting_system/extrusion-coating/. For more information and SIG products, please visit https://www.sig.biz/en.

Hot off the press is our first Global Review Newsletter of 2020! There is so much happening at Davis-Standard and we want to share our latest news and updates with you. Click below to read volume 48.