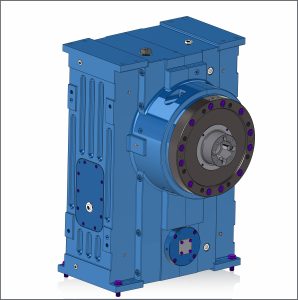

Davis-Standard is pleased to introduce its next-generation gear reducer. This sleek new design represents a commitment to customer feedback, field experience, and technical engineering while building upon the robust performance synonymous with Davis-Standard gear reducers. The new reducer fulfills a variety of extrusion requirements, including those with high and low torque, speeds and extrusion pressures. It can also accommodate the DS Activ-Check™ system, Davis-Standard’s Industry 4.0 platform for continuous monitoring, preventative maintenance and mobile alerts.

Davis-Standard is pleased to introduce its next-generation gear reducer. This sleek new design represents a commitment to customer feedback, field experience, and technical engineering while building upon the robust performance synonymous with Davis-Standard gear reducers. The new reducer fulfills a variety of extrusion requirements, including those with high and low torque, speeds and extrusion pressures. It can also accommodate the DS Activ-Check™ system, Davis-Standard’s Industry 4.0 platform for continuous monitoring, preventative maintenance and mobile alerts.

“Our next-generation reducer represents strategic engineering and the application of cumulative knowledge to deliver greater functionality without compromising performance,” said Gary Peacock, Davis-Standard’s director of engineering. “We’ve improved all major components and packaged them in a redesigned housing. We already have hundreds of extruders fitted with the new reducer in the field. Customers across all Davis-Standard applications are pleased with the results.”

The new gear reducer is available in five different dimensions and capacities for extruders ranging from 2 inches (50mm) to 6.5 inches (165mm) in size. Following is a summary of advantages:

Horizontal and vertical orientations – The horizontal orientation is a good fit for belt-driven machines and/or low centerlines. This allows for a range of belt drives, versatile feedscrew timing, and adaptability to direct-coupled drives. The vertical housing arrangement is designed for direct-coupled and narrow footprint machines. It allows for tight positioning of extruders used in multilayer processes.

Cooling and lubrication – There are two cooling and lubrication options based on housing style and customer requirements. These include oil bath lubrication and partial immersion/forced lubrication.

Gears and roller bearings – Case-hardened precision ground helical gearing is available in a wide range of gear reduction ratios to suit process requirements. New to this reducer series are spherical roller thrust bearings which absorb the axial process load and provide a self-centering, compact design with superior low-friction characteristics.

Radial shaft seals – All reducers are fitted with high-quality, spring-loaded radial shaft seals to contain lubrication oil and exclude contaminants.

Felt excluder – A felt ring excluder has been added to the front output shaft to protect the shaft and seal from abrasion and extend seal life.

Housing design – Durable cast iron construction provides quiet operation and minimal vibration. Large inspection ports simplify viewing of gear tooth condition, and a non-vented, bullet-type oil sight check eliminates the potential for leakage. Large oil fill ports allow for easier filling, while a low point drain port enables complete draining. A front thrust shaft cover completely encloses the reducer housing, allowing for more precision seal-to-shaft alignment.

Retrofitting to older machines – There are many opportunities to retrofit the Next Gen gearcase to older extruders. Please contact Davis-Standard’s Aftermarket team to see if this applies to your existing machines.

For more information about the new gear reducer, contact marketing or visit our contact us page to submit your inquiry.