Davis-Standard is pleased to announce that Zachary Ament has been promoted to Executive Vice President effective March 6, 2020. He will replace longtime Davis-Standard employee and team leader Ernie Plasse who is retiring. Ament has been with Davis-Standard for over seven years, most recently serving as Vice President of Business Development. In that role, he has been heavily involved in the development and tactical execution of Davis-Standard’s organizational strategy across the global organization including mergers, acquisitions, strategic agreements and more, positioning him well to assume Plasse’s role.

“Ernie’s leadership, industry knowledge and vast experience will be greatly missed,” said Jim Murphy, Davis-Standard’s President and CEO. “He’s had an extraordinary 46-year career at Davis-Standard. His humility and work ethic set an excellent example for our entire team at Davis-Standard, and we wish him all the best in retirement.” Murphy added, “Zachary will do an outstanding job in this role and has been working alongside Ernie to ensure a smooth transition. We look forward to his perspective and leadership as we continue our commitment to outstanding customer service.”

Plasse began his career as a stockroom clerk at Sterling Blow Molding, (a Davis-Standard brand) in 1973, and assumed greater roles of responsibility in the years to come, eventually becoming the vice president of manufacturing at Sterling. He relocated to Davis-Standard’s headquarters in Pawcatuck, Conn., in 1994. Plasse continued to excel in various leadership roles, leading to his current role as executive vice president – aftermarket in 2013. The entire Davis-Standard family wishes him well in retirement.

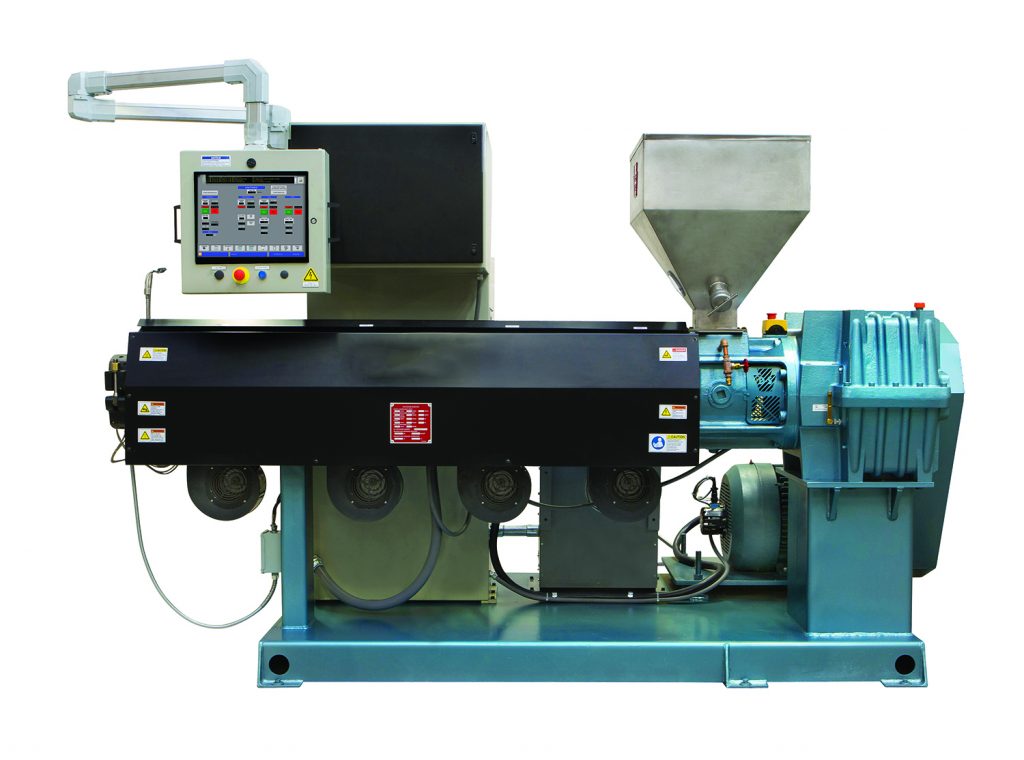

Davis-Standard, LLC will exhibit a running TPE tubing and ABS filament line at booth 4024 during MD&M West in Anaheim, Calif., February 11 – 13, 2020. The line will demonstrate processing versatility by running TPE tubing on the first two days of the show and ABS filament on day three. The line is capable of processing a variety of flexible tubing materials at speeds up to 300 feet per minute (91 mpm).

Davis-Standard, LLC will exhibit a running TPE tubing and ABS filament line at booth 4024 during MD&M West in Anaheim, Calif., February 11 – 13, 2020. The line will demonstrate processing versatility by running TPE tubing on the first two days of the show and ABS filament on day three. The line is capable of processing a variety of flexible tubing materials at speeds up to 300 feet per minute (91 mpm).

Davis-Standard is pleased to announce that Rich Kanarski has been appointed Manager – Technical Product Management. Effective January 1, he will lead efforts to drive the evolution of technologies associated with key product lines in support of Davis-Standard’s strategic plan. The new role involves a combination of tactical and strategic activities centered on advancing product performance. Kanarski and his team will collaborate with suppliers and customers to evaluate market trends and capabilities and develop technology accordingly.

Davis-Standard is pleased to announce that Rich Kanarski has been appointed Manager – Technical Product Management. Effective January 1, he will lead efforts to drive the evolution of technologies associated with key product lines in support of Davis-Standard’s strategic plan. The new role involves a combination of tactical and strategic activities centered on advancing product performance. Kanarski and his team will collaborate with suppliers and customers to evaluate market trends and capabilities and develop technology accordingly. In an effort to continually improve system productivity through smarter technology, Davis-Standard has introduced the Model 3000A (automatic) crosshead for rubber hose applications. As overhead costs for labor, energy and materials put pressure on the margins, it is essential to have faster, more versatile equipment to merge economics with sustainability. The Model 3000A crosshead is an example of this technology, enabling hose manufacturers to reduce scrap and attain faster start-up times for smaller lots. Material savings, quick product changes, simplified maintenance, reduced scrap and improved quality equate to competitive efficiency.

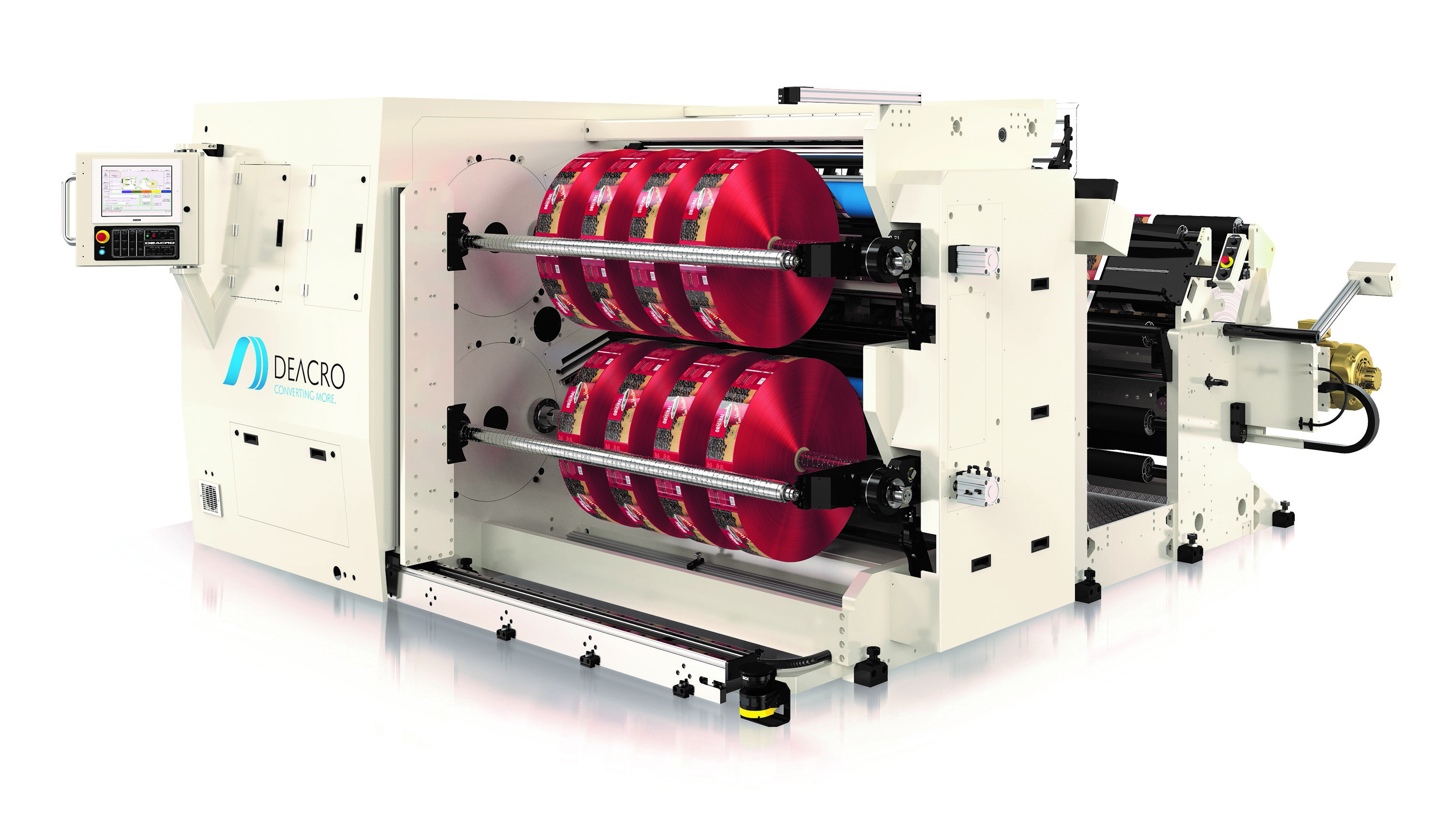

In an effort to continually improve system productivity through smarter technology, Davis-Standard has introduced the Model 3000A (automatic) crosshead for rubber hose applications. As overhead costs for labor, energy and materials put pressure on the margins, it is essential to have faster, more versatile equipment to merge economics with sustainability. The Model 3000A crosshead is an example of this technology, enabling hose manufacturers to reduce scrap and attain faster start-up times for smaller lots. Material savings, quick product changes, simplified maintenance, reduced scrap and improved quality equate to competitive efficiency. Davis-Standard, LLC announced today that it has acquired Deacro Industries, Ltd (“Deacro”) of Mississauga, Ontario. Deacro (

Davis-Standard, LLC announced today that it has acquired Deacro Industries, Ltd (“Deacro”) of Mississauga, Ontario. Deacro (