Recent News

Past News

Running FEP Line to Showcase Best-in-Class Technology

Running FEP Line to Showcase Best-in-Class Technology

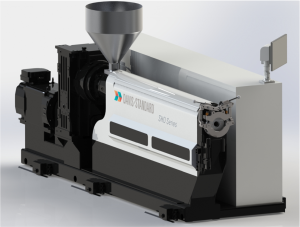

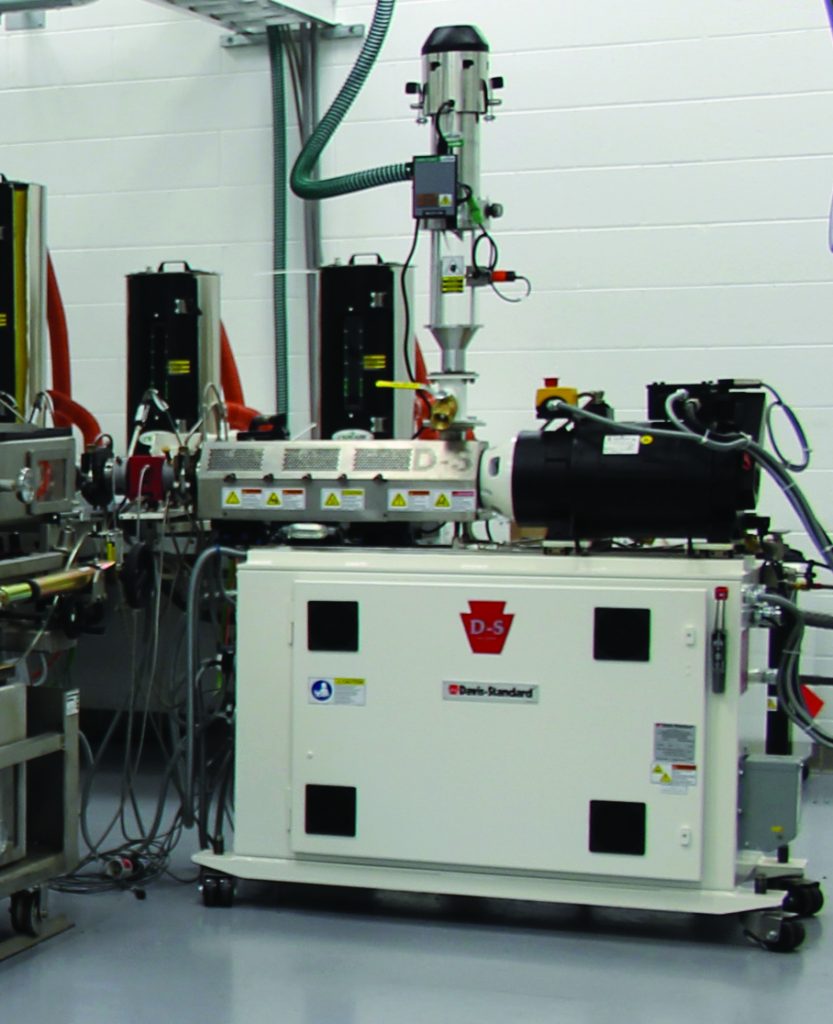

The technologies of Davis-Standard, Conair, Zumbach and other industry-leading companies will be on display with a running FEP line at MD&M West in Anaheim, Calif., February 5-7, 2019 at booth 3839. The coextrusion line will be processing FEP medical tubing with three barium sulfite stripes. The line will be equipped with two of Davis-Standard’s MEDD (Medical Extruder Direct Drive) extruders along with Conair MedLineTM upstream and downstream equipment, Zumbach gauging, Guill die tooling and resins supplied by Daikin and PolyOne Colorant Chromatics. MD&M is the largest medical technology show in North America, making this the ideal venue to demonstrate Davis-Standard’s medical tubing capabilities alongside industry partners.

According to Dr. Jason Baird, senior process engineer at Davis-Standard, this line demonstrates the value of long-term collaboration to meet the functional and versatile tubing demanded by the medical industry. “The tubing at the show will feature three stripes and will represent the latest technology required for processing barium sulfite products,” he said. “One of the greatest advantages of this line is that it gives the processor the option to lay the stripes on the outside of the tubing or embed them within the tubing wall. Every component is engineered for tight tolerances, high-quality and output efficiency.”

Specific to Davis-Standard, the MEDD extruders will demonstrate the value of an extruder designed specifically for medical environments. The MEDD enables processors to easily swap barrels and/or feedsection liners to change extruder diameter and/or length while keeping alignment intact, providing versatility in cleanroom settings where space is limited. The extruder’s direct drive design eliminates the need for gearcase oils and belts that create particulates, and the machine is mounted on linear rails to make seamless adjustments with or without a melt pump. At the MD&M show, both extruders will have ¾-inch (19mm) diameter barrels with L/D’s of 24:1 and 16:1. In order to limit exposure of the radio-opaque barium sulfate filler to the high temperatures of fluoropolymer processing, a shorter 16:1 extruder along with special screw design will be used. All components of the tubing line will be monitored and controlled by Davis-Standard’s eVUE control system.

According to Kevin Dipollino, Davis-Standard’s product manager of pipe, profile and tubing, “This line represents an all-encompassing package in both design and processing technology. It shows the value of complementary components among reputable industry partners in creating an end-to-end solution that addresses a growing segment within the medical tubing marketplace.”

For more information about Conair, visit www.conairgroup.com. For more information about Zumbach, visit www.zumbach.com.

![]()

In an ongoing effort to strengthen efficiencies and customer satisfaction, Davis-Standard’s Pawcatuck facility recently became ISO 9001:2015 certified. The certification validates Davis-Standard’s processes across the board, internally and externally, and serves as a benchmark for the company’s commitment to operational quality and process improvement.

“ISO requires the implementation of a demonstrated quality management system, promoting a holistic approach to evaluating your operation,” said Mike Newhall, Davis-Standard’s Vice President of Operations. “It has driven corrective action where we’ve needed it, and has made every aspect of our business better. This encompasses everything from how we on-board employees and review customer specifications to our engineering and manufacturing practices. There is no stone left unturned, which results in an improved capacity to achieve customer expectations each and every time.”

At the core of ISO certification is the ability to consistently provide products and services that meet customer and applicable statutory and regulatory requirements while also enhancing customer fulfillment through an effective quality management system (www.iso.org). Because of this, Newhall noted that all issues are addressed at the source.

“The ISO process is invaluable in making every department better,” said Newhall. “It’s also just the beginning. It is a continuous improvement process to improve our performance in all areas of the business. Being ISO certified gives our employees and customers the assurance the system is accessed and approved on a regular basis. It is a sustainable approach that holds us accountable to what we promise with the Davis-Standard brand.”

For more information, contact Mike Newhall at mnewhall@davis-standard.com.

Photo Caption: ISO 9001 2018 Certification Logo

Davis-Standard, LLC announced today that it has acquired Thermoforming Systems LLC (“TSL”) of Yakima, Washington. TSL (www.tslusa.biz) designs, manufacturers and markets leading-edge thermoforming equipment to the North American food packaging industry.

Davis-Standard, LLC announced today that it has acquired Thermoforming Systems LLC (“TSL”) of Yakima, Washington. TSL (www.tslusa.biz) designs, manufacturers and markets leading-edge thermoforming equipment to the North American food packaging industry.

“TSL is the market leader in thermoforming equipment technology for high volume packaging and we are excited to welcome their dedicated team to Davis-Standard today,” said Jim Murphy, Davis-Standard President and CEO. Murphy added, “We are enthusiastic about this opportunity with TSL, as we share core values and a focus on our customers, technology and product innovation.”

James Naughton, President of Thermoforming Systems LLC, remarked on the transaction.

“Davis-Standard has a long-standing reputation as the global leader in extrusion technology and was our preferred partner to work with,” he said. “We are very pleased to join an organization that shares our business principles, and together with Davis-Standard, TSL looks to deepen its commitment to our customers and employees. TSL will continue to operate and serve its customers as before and we are enthusiastic about our unique product opportunities with Davis-Standard.”

Murphy concluded with, “This is an exciting day for both organizations as we begin our future together.”

Caption 1:

Jim Murphy, President & CEO of Davis-Standard shakes hands with James Naughton of Thermoforming Systems LLC (TSL)

Caption 2:

Thermoforming Systems LLC (“TSL”) designs, manufacturers and markets leading-edge thermoforming equipment to the North American food packaging industry.

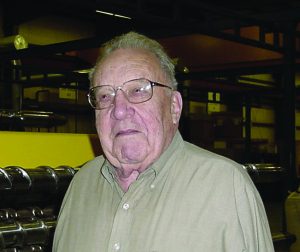

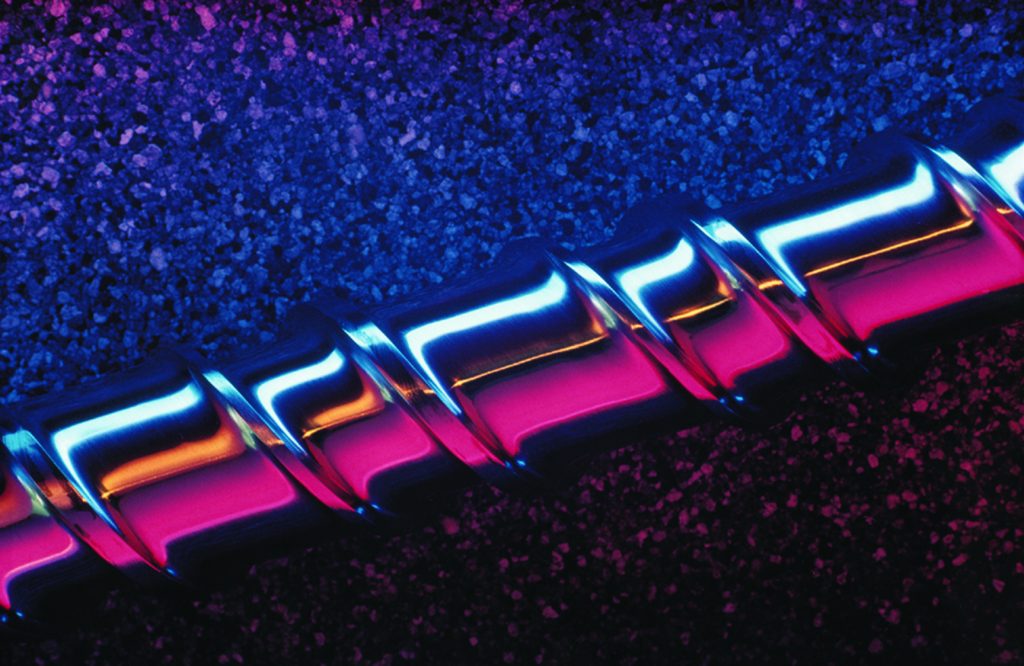

Norton C. Wheeler, Jr., one of Davis-Standard’s most beloved and accomplished technology innovators passed away the end of September at his home in Mystic, Conn. He was 96. Wheeler’s distinguished career at Davis-Standard spanned six decades. Even after his retirement in 1989, he remained engaged as a consultant until the age of 90. He is known as the father of the DSB® (Davis-Standard Barrier) feedscrew, authored numerous technical papers, and mentored many Davis-Standard engineers. His list of contributions to Davis-Standard and the plastics industry, in general, is extensive. He was awarded Fellow of the Society of Plastics Engineers in 1985 and received the Bruce C. Maddock Award in 1998 for his pioneering work in research and development.

Norton C. Wheeler, Jr., one of Davis-Standard’s most beloved and accomplished technology innovators passed away the end of September at his home in Mystic, Conn. He was 96. Wheeler’s distinguished career at Davis-Standard spanned six decades. Even after his retirement in 1989, he remained engaged as a consultant until the age of 90. He is known as the father of the DSB® (Davis-Standard Barrier) feedscrew, authored numerous technical papers, and mentored many Davis-Standard engineers. His list of contributions to Davis-Standard and the plastics industry, in general, is extensive. He was awarded Fellow of the Society of Plastics Engineers in 1985 and received the Bruce C. Maddock Award in 1998 for his pioneering work in research and development.

“I was honored to know Norton and work alongside him for so many years. He was a great mind, problem-solver and infinite resource. He was also a wonderful human being, always willing to give of himself in his modest way,” said John Christiano, Davis-Standard’s Vice President of Extrusion Technology. “Our R&D capabilities and technical leadership began with Norton and he remained so vital to our work throughout his life. His achievements not only defined Davis-Standard as an R&D leader, but they changed the industry. He was truly one of a kind and will be dearly missed.”

Being part of Davis-Standard was in Wheeler’s blood. His grandfather, Charles E. Wheeler, was an original owner of Davis-Standard, purchasing the business as the Standard Machinery Company in 1904. His father Norton Sr. and his uncle John were instrumental in assisting their father with modernizing and diversifying the operation. Under the leadership of Wheeler’s father, company president in the 1940s, and his new partner Benjamin Davis, the company transitioned from a manufacturer of compression molding presses before and during World War II into a post-war manufacturer of extrusion machinery. The company became Davis-Standard in 1948.

Wheeler joined Davis-Standard in 1951 after serving in the U.S. Air Force and graduating from Brown University with a chemistry degree. Wheeler was a natural in the research environment. He spearheaded Davis-Standard’s first lab in the 1960s, growing the facility from a small space to a building equipped for customer trials and extensive R&D within a decade. During the following 20 years, he conducted revolutionary research with regard to feedscrew design and extrusion process control. Of all of his achievements, Wheeler was most proud of the fact that Davis-Standard was the first company to fully instrument an extruder with multiple pressure transducers.

In the early 1980s, Wheeler patented the well-known DSB screw design. This design overcame limitations of existing barrier screws by optimizing the screw’s melt region, leading to improved stability and performance. The DSB quickly became the industry’s premier feedscrew and gave Davis-Standard a global technical presence. It also helped the company expand into multiple processing areas such as pipe and profile and sheet. The DSB continues to be the basis for all Davis-Standard screw designs.

Wheeler was predeceased by his wife of 69 years, Mary Anderson Wheeler, and is survived by their five children, six grandchildren and eight great-grandchildren.

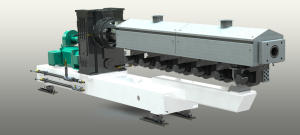

To support ongoing growth in feedscrew manufacturing, Davis-Standard is installing its fourth CNC machining center at its facility in Pawcatuck, Connecticut. The $2 million investment will further boost production efficiency and will enable Davis-Standard to increase feedscrew production by over 25 percent. The machining center is expected to be operational by mid-October.

To support ongoing growth in feedscrew manufacturing, Davis-Standard is installing its fourth CNC machining center at its facility in Pawcatuck, Connecticut. The $2 million investment will further boost production efficiency and will enable Davis-Standard to increase feedscrew production by over 25 percent. The machining center is expected to be operational by mid-October.

“This investment reflects our continued commitment to best practices in manufacturing and in supporting customers with best-in-class feedscrew technology,” said Mike Newhall, Davis-Standard’s Vice President of Operations. “The CNC machining center being installed is the same brand as our existing machines, Weingartner, which makes software programs and tooling interchangeable. We also have highly skilled machinists already trained to run this type of equipment. This will further add to our ability to meet customer demand and improve our overall responsiveness to our customer’s requirements.”

The additional center is a Weingartner Pickup 700 Whirler, capable of machining feedscrew sizes that comprise 80 percent of Davis-Standard’s screw volume. This includes feedscrews from 1.5 inches (38mm) to 6 inches (152mm) in diameter and in lengths up to 207 inches (5,200mm). The machine will augment existing capabilities in Davis-Standard’s feedscrew operation, which currently manufactures over 1,000 feedscrews annually. It will also support feedscrew cycle time reduction, enabling the company to improve delivery times and maintain a steady stock of feedscrews in various sizes and finishes.

By Lisa McTigue Pierce in Flexible Packaging on August 29, 2018

By Lisa McTigue Pierce in Flexible Packaging on August 29, 2018

Technological innovation, sustainability concerns and attractive economics are among the reasons for the phenomenal growth of flexible packaging in the last two decades in the U.S. With an estimated $31 billion in sales in 2017, according to the Flexible Packaging Assn., brand owners are embracing films, pouches and bags as a go-to packaging solution, thanks in part to wide acceptance by American consumers.

But we’re also seeing aluminum sourcing concerns because of U.S. tariffs, as well as major competitive moves—reflected, for example, by the recent Amcor acquisition of Bemis.

With flexible packaging so much in the spotlight, Packaging Digest wanted to see what is shifting in the market. So we conducted a virtual roundtable with five industry experts from various areas in the supply chain: resin supplier Nova Chemicals (page 1); printing press maker Comexi (page 2); extrusion/coating equipment company Davis-Standard (page 3); converter Berry Global (page 4); and form-fill-seal machinery manufacturer Pro Mach (page 5).

Their insights show how this dynamic market continues to advance, despite some challenges.

Here are the questions we asked:

1. What top trends are you seeing in flexible packaging and why? What are the drivers?

2. What challenges is the flexible packaging market encountering now and how are they being addressed?

3. Where do you see the biggest growth for flexible packaging moving forward and why?

4. What, if anything, is different about the sustainability message of flexible packaging today versus, say, two or three years ago?

Now, the insights from…

Page 1: Jonathan Quinn, performance films market development manager, Nova Chemicals, a plastics and chemical company that makes resins for flexible packaging.

Page 2: Raúl El-Fakdi, flexo brand manager, Comexi, a family-run manufacturer of flexographic printing, offset printing, gravure printing, laminating and slitting equipment.

Page 3: Louis Piffer, senior sales engineer, Davis-Standard, a designer, manufacturer and supplier of plastics and rubber processing equipment, and extrusion technology and extruder converting systems.

Page 4: Tarun Manroa, evp and general manager, engineered materials division, Berry Global, a Fortune 500 global manufacturer and marketer of plastic packaging products, including pouches.

Page 5: Troy Snader, svp, flexible packaging, Pro Mach, a comprehensive provider of complete packaging machinery solutions, from line design to the end of the line and beyond.

Jonathan Quinn, performance films market development manager, Nova Chemicals, a plastics and chemical company that makes resins for flexible packaging.

What top trends are you seeing in flexible packaging and why? What are the drivers?

Quinn: From an economic perspective, trends like consolidation—such as Amcor’s announcement to acquire Bemis—clearly will continue, and we also will see some further uncertainty related to the trade war. Regardless, we believe that packaging trends in the North American market place are driven by the consumer. And three major consumer trends are sustainability, convenience and ecommerce.

1. Sustainability: Shifting demographics and consumer preferences are driving the demand for more sustainable solutions, in packaging and far beyond. Negative publicity around ocean gyres and plastic-filled beaches only add to the urgency to increase recyclability, curbside collection, sorting capabilities and finally innovation to increase demand for recyclable materials. Rigid-to-flexible conversion, with its huge sustainability benefits, has been a trend for some time now. Add to all of these the opportunities resulting from more cost-effective and technologically feasible recyclable packaging solutions available today, and sustainability is at the top of everyone’s list.

We are at a unique point in the history of flexible packaging. According to the New Plastics Economy, major brand owners and retailers—including Danone, Mars, PepsiCo and Coca-Cola, and Walmart—are working towards goals around all reusable, recyclable or compostable packaging, and these initiatives are speeding the shift to recyclable flexible packaging.

There is also a significant push by flexible packaging companies for sustainable packaging today. All in all, we’re seeing a critical mass of players moving the needle, after many years of talking about the need for action.

2. Convenience, convenience, convenience! The consumer of today is very different than that of the traditional consumer 20 years ago. The younger generations’ typical lifestyle is busier and busier, and at the same time, they’re looking for healthier options—that often require performance packaging. Everyone is on the go and these buyers want the products they consume to be delivered quickly, consumed easily and disposed of efficiently.

3. Ecommerce: Ecommerce is a game-changing example of the convenience trend. Its efficiencies, coupled with the ease of comparison shopping, are also driving down prices in many sectors. As Business Insider reports, ecommerce is driving virtually all retail growth, and its impact on flexible packaging will grow with it.

According to FMI, the online grocery market alone may reach $100 billion by 2022. Better performing flexible packaging solutions—especially seal integrity and abuse resistance so products arrive at the consumer’s door intact—will be a must to support the more rigorous ecommerce supply chain.

What challenges is the flexible packaging market encountering now and how are they being addressed?

Quinn: We see three challenges, as well.

1. Speed of transformative change: The biggest challenge we see moving forward is innovating at the rate of speed required to keep up with rapidly evolving business models. The meal kits delivery business is a great example. In 2018, we are going to get a good idea if this market segment is going to sink or swim. A key driver for it to survive and thrive will be packaging performing at the highest levels, providing consumer confidence that every week their food will arrive fresh and safe to consume. The “safe to consume” aspect will be that the products be efficiently packaged in well insulated secondary package. In addition, meal kit customers feel the amount of packaging is excessive and non-recyclable, according to a Packaged Facts report, so primary and secondary packaging will also have to have a sustainable format.

2. Consumer perception of plastics: Anti-plastics sentiment continues to rise, both in absolute numbers and relative to perceptions of alternative materials. Consumers are being exposed to media and publications showcasing the negative aspects of one-time-use plastics. Municipal bag bans are cropping up and companies like McDonald’s are discontinuing the use of styrenics, among other moves across the globe.

Our industry can and must do a better job of helping consumers see the benefits of plastics in the context of the total lifecycle environmental footprint. We need to go even further, and help to develop the circular economy, which today is just starting to take shape.

3. Personalizing the consumer experience: Everything from Coke bottles and cans to candy bars are being marketed as a unique experience for each and every consumer. This trend started in the digital realm and now younger consumers especially expect it with their goods as well. As a result, companies are being forced to find new ways to connect with consumers and give them an individualized experience. The challenge lies both in increased costs to deliver on this experience, and the enormous logistical challenges in implementation.

Where do you see the biggest growth for flexible packaging moving forward and why?

Quinn: The big trends noted above are the main drivers of growth in flexible packaging. Here’s why…

Sustainability: A lot of growth in flexible packaging is about conversion that improves sustainability. The first wave was in rigid to flexible, which continues to grow the flexible market tremendously while reducing total lifecycle environmental impact as noted above. The next wave is the move to mono-material and other recyclable film structures, whether from non-recyclable multi-material construction or leapfrog conversions from alternative materials. We see the advent of recyclable performance packaging accelerating the growth of flexible packaging tremendously.

Convenience: Kids have been leading the way in some respects in single serve and on-the-go packaging. Examples include packs of apple slices and carrot sticks, pureed baby food in SUPs with fitments and now squeeze packs of applesauce, or going way back to things like Lunchables. We’re now seeing expansion in products like this marketed to adults. Brands are introducing products like retort oatmeal in a SUP with a fitment, and we’re even starting to see convenience products in the produce aisle. For example, Dole is now offering pineapple and watermelon individually sliced and wrapped in a flow wrap, then collated into a secondary package.

Granola and protein bars really speak to this trend and growth, even though we don’t think of them this way. They’re designed to be the perfect on the go refuel!

3. Ecommerce: We’ll see growth in ecommerce flexible packaging related to application customization. The major drivers—“frustration free” packaging and “ships in own container”—enhance the consumer experience and they’re going to drive flexible into applications where it has not historically been. We’re seeing things like using shrink wrap over a primary packaging box instead of a second box, and products traditionally packaged in clam shells and a secondary shipping box transitioning to an easy-open, abuse-resistant, and tamper-evident pouch or other primary package format.

The sustainability benefits of lighter weight flexible packaging will also come into play in ecommerce. Converting to flexible packaging can reduce material costs, shipping costs and ease logistical challenges. These take cost out of the supply chain for the retailer and the shipper and may in turn lower the retail price for the consumer. Products which needed to be merchandised for the retail environment don’t have the same requirement when sold online, which allows for different package formats and branding.

Ultimately, the result will likely be convergence, where one package format and structure can be used for both brick and mortar and ecommerce sales. These packages will incorporate the performance and aesthetic requirement of both sales channels, and offering an overall cost advantage over multiple stock-keeping units (SKUs) for identical products.

What, if anything, is different about the sustainability message of flexible packaging today versus, say, two or three years ago?

Quinn: We see a couple of different perspectives on this. First is the messaging opportunity to consumers, which often takes center stage. However, communication within the industry is also essential to developing and commercializing more sustainable packaging offerings.

Consumer messaging: Today, sustainability is a true driver of packaging innovation, where just a few short years ago it was just a buzzword. Again, shifting demographics come into play. Younger generations have a less positive perception of plastics, and sustainable packaging is an imperative to appeal to these consumers. Programs like How2Recycle label are helping consumers understand flexible packaging recycling options, and enabling brand owners to showcase package recyclability, educate consumers and ultimately drive up collection rates. Industry associations are also starting to step up with concerted efforts to promote the benefits of plastics over alternative materials, counterbalancing some of the anti-plastics sentiments we all see in the media.

Flexible packaging sustainability messaging is also focused on reducing waste in general. Newer technologies are enabling downgauging and related benefits in flexibles that reduce material consumption and waste. These packages also play a role in reducing food waste by extending shelf life and reducing spoilage from leakers and other package breaches. As a result, the messaging now is around the positive influence flexible packaging has on sustainability in the entire value chain.

In short, the message is changing. Sustainability is driving action and resources for all of us in the broader plastic packaging industry.

Within the industry: Sustainability is both a challenge and an opportunity throughout the value chain. We can’t find optimal solutions in isolation; we are all interdependent and must collaborate to develop the environmentally responsible packaging that consumers and brand owners are demanding. More and more industry players understand the sustainability opportunity today, and they understand that how we talk to each other about it is essential, as it influences how quickly and even whether a lot of innovation happens.

Also, no discussion of the sustainability of flexible plastics would be complete without noting the impact of China’s National Sword initiative. This initiative is increasing the amount of recyclable materials that need to be consumed domestically by a huge percentage. We’re going to have to think differently about how to expand the profitable uses of flexible recyclables to consume those additional materials.

https://www.packagingdigest.com/flexible-packaging/how-flexible-packaging-trends-are-shifting-and-why-2018-08-29

A recent feedscrew replacement has boosted rates by more than 33 percent for Davis-Standard customer Swan® Products, LLC. Swan Products, the leading North American manufacturer of water hoses for consumer and industrial markets, installed four new feedscrews on existing Davis-Standard extruders at one of its plants in Canada. From order to installation, the project took about two and a half months, saving the company time and money by providing a cost-efficient means to increase productivity.

A recent feedscrew replacement has boosted rates by more than 33 percent for Davis-Standard customer Swan® Products, LLC. Swan Products, the leading North American manufacturer of water hoses for consumer and industrial markets, installed four new feedscrews on existing Davis-Standard extruders at one of its plants in Canada. From order to installation, the project took about two and a half months, saving the company time and money by providing a cost-efficient means to increase productivity.

“We were able to replace feedscrews on older machines and improve throughput by over 33 percent,” said Jose Rossi, Director of Manufacturing, North America for Swan Products. “We appreciate Davis-Standard’s lab facility at its headquarters in Pawcatuck, Connecticut, which enabled us to prove design concepts alongside feedscrew engineers with hands-on experience. They are very thorough in their management and delivery.”

The new high-throughput designs included one 2.5-inch (50mm) and three 4.5-inch (114mm) feedscrews. The trip to Davis-Standard’s lab in Pawcatuck proved valuable since Swan needed capabilities to process both PVC and TPV resins. During the trial, several designs were tested to determine the best options for outputs and stability specific to Swan’s process requirements. According to Jason Baird, the senior process engineer at Davis-Standard who conducted Swan’s trial, working with Rossi at the lab was essential to ensuring desired outcomes without worrying about hypotheticals.

“We have analytical capabilities at the lab that enable us to see what’s going on inside the extruder as we test different feedscrews. When you improve output rates, you also need to confirm stability to achieve uniform product,” explained Baird. “Swan supplies garden hoses to major big box stores, so quality and consistency are essential to their business. We were able to verify both outputs and stability while also evaluating every aspect of performance from melt temperature to torque. This gave Swan the validation they needed to achieve immediate results.”

Davis-Standard offers a complete menu of R&D, feedscrew replacement and rebuilding services. Feedscrews are available in sizes ranging from a 3/4-inch (20mm) to 12 inches (305mm) in diameter and with different L/D options. Feedscrews can be designed for any extruder brand and barrel. In addition to feedscrew replacement, Davis-Standard offers barrel measurement services to ensure dimensional fit and best performance. In most cases, quotes for new feedscrews are available within a day. Lab trials can be scheduled to accommodate customer timelines and processing requirements.

For more information about Swan Products, visit www.swanhose.com. For more information about Davis-Standard feedscrews and aftermarket capabilities, visit Parts and Upgrades on our website.

In response to the increased demand for “smart” technology, Davis-Standard is pleased to announce its DS Activ-Check™ system for continuous extruder monitoring. This technology was demonstrated at NPE and is an available option with Davis-Standard’s Integrator, EPIC III® and DS-eVue control systems.

In response to the increased demand for “smart” technology, Davis-Standard is pleased to announce its DS Activ-Check™ system for continuous extruder monitoring. This technology was demonstrated at NPE and is an available option with Davis-Standard’s Integrator, EPIC III® and DS-eVue control systems.

DS Activ-Check™ enables processors to take advantage of real-time predictive maintenance by providing early notifications of potential extruder failures. Machine operators are alerted to issues before they happen, reducing unplanned downtime while also collecting valuable data. Users receive notifications via e-mail or text, and continuous monitoring of production machine status is available on smart devices and remote PCs. Key parameters monitored include extruder reducer, lubrication system, motor characteristics, the drive power unit, barrel heating and cooling.

The system is easy to operate due to overview screens that provide a quick reference of monitor points and trend windows, providing a graphic indication of measurements. Users can touch a location to view details or use on-screen set-up for e-mail or text notifications. Vibration sensors on the extruder reducer provide data regarding the condition of the gears, bearings and lubrication system. The extruder motor is supplied with combination temperature sensors and vibration sensors. The reducer lubrication system (If provided), includes pressure, flow and temperature sensors to indicate system performance. Operators are also able to monitor key health indicator parameters in the drive power unit, providing an early indicator of potential power unit issues.

“The DS Activ-Check™ system provides much-needed data for processors to improve performance, including being able to plan production around scheduled maintenance activities,” said John Clemens, Director of Extrusion Controls at Davis-Standard. “Having the capability to monitor extrusion line variables such as mechanical and electrical system conditions is essential in order to bring products to market faster and minimize unplanned downtime. This technology will also allow customers to address a pending condition that could become a more serious issue in the future. All of this is valuable and much-needed knowledge to strengthen existing extrusion and converting processes.”

For more information about DS Activ-Check™ - contact us today!

Davis-Standard will be offering its popular extrusion seminar, “The Basics of Plastics Extrusion,” on October 9 – 10, 2018 at its headquarters in Pawcatuck, Conn. The two-day class covers the fundamentals of plastics extrusion, as well as the composition and properties of various polymers and the mechanics of essential downstream processes. Seminar topics include extruder components, temperature control, maintenance and screw design.

Davis-Standard will be offering its popular extrusion seminar, “The Basics of Plastics Extrusion,” on October 9 – 10, 2018 at its headquarters in Pawcatuck, Conn. The two-day class covers the fundamentals of plastics extrusion, as well as the composition and properties of various polymers and the mechanics of essential downstream processes. Seminar topics include extruder components, temperature control, maintenance and screw design.

In addition to instruction, course participants will tour Davis-Standard’s Technology Center and manufacturing facility and will have access to polymer process engineers and technical specialists. The fee is $750 per person with a 10 percent discount given for groups of three or more. Course books and materials are included, and class size is limited to promote student and teacher interaction.

For enrollment details or more information about this seminar, contact Nichole Denerley at ndenerley@davis-standard.com.

Davis-Standard, a leading provider of polymer processing equipment and customer support solutions, has revealed the next evolution of its global brand to European customers. The new identity and messaging strategy is designed to better express the company’s customer-centric and forward-looking business approach. It is also expected to provide customers and prospects worldwide with a more unified and compelling visual experience when interacting with Davis-Standard marketing and web resources.

The previous Davis-Standard brand dates back to the 1950s-60s, when Ben Davis joined Standard Machinery Co. to create the Davis-Standard name. The original company, Reliance Machinery Co., was founded in 1848 and manufactured cotton gins and paper binding machines. Extrusion was developed in the 1950s. “We previously branded ourselves as ‘The Global Advantage,’ and we’ve executed that by expanding our global facilities and capabilities over the years. But now the focus is now more squarely on helping our customers execute, to better understand their requirements, to build stronger relationships and trust, and to provide the best total solutions,” states Jim Murphy, President and CEO.

“Davis-Standard is recognized all over the world for equipment reliability and customer support, but we felt our brand wasn’t fully reflective of our standing in the industry,” continues Murphy. “We are leading the way in providing the solutions that help our customers be more competitive in today’s marketplace. We now have a brand that better speaks to that leadership. We have been on an upward trajectory and now is the time for our brand to embody what we have become, and still intend to become.”

Kai Moellendorf, Managing Director of Davis-Standard’s subsidiary in Germany added, “The new brand positively reflects the global nature of Davis-Standard and all the brands it represents. This includes our customer-centric focus at ER-WE-PA in Germany and Davis-Standard Limited in the U.K. The tagline ‘Where your ideas take shape’ fits well with our objectives of developing polymer processing solutions that optimize productivity and profitability. We aim to help customers create a better future with teamwork and collaboration.”

The brand refresh includes a new logo – the first logo update in nearly 50 years – and a brighter image. It also includes an updated brand story, a new website and customer experience.

For more information about Davis-Standard, visit www.davis-standard.com.

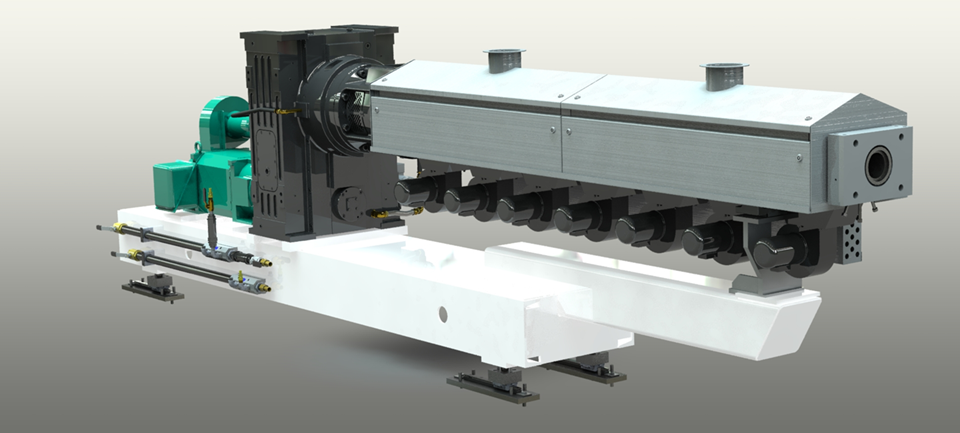

Continual growth in product demand and a full manufacturing floor required Intralox to get creative with their processing options. Intralox, a global leader in plastic conveyor belt technology, recently replaced an older profile line with a new Davis-Standard dual-strand profile line, doubling their output without requiring additional space. The line processes dual-strand solid rod made of PP, PE, PA, Acetal and PEEK materials. Davis-Standard customized the line for Intralox applications, completing delivery and installation within eight months of purchase. The project was so successful, Intralox plans to replace its other profile lines with Davis-Standard dual-strand lines in the near future.

Continual growth in product demand and a full manufacturing floor required Intralox to get creative with their processing options. Intralox, a global leader in plastic conveyor belt technology, recently replaced an older profile line with a new Davis-Standard dual-strand profile line, doubling their output without requiring additional space. The line processes dual-strand solid rod made of PP, PE, PA, Acetal and PEEK materials. Davis-Standard customized the line for Intralox applications, completing delivery and installation within eight months of purchase. The project was so successful, Intralox plans to replace its other profile lines with Davis-Standard dual-strand lines in the near future.

“This new line is a game-changer in terms of production outputs, rod quality and innovation,” said Gregory Washington, Extrusion Supervisor at Intralox. “While dual-strand profile technology is not new, it’s new for us. We’ve had great results in terms of speed, equipment performance and ease of operation. Davis-Standard’s professionalism and craftsmanship culminated in a perfect solution for our processes. Their team went the extra mile in all aspects including design, factory acceptance testing and installation. Successes like this don’t happen accidentally; it takes intentional team commitments and leadership.”

Davis-Standard supplied all line components from extruder and controls through downstream equipment. Washington appreciates the intuitiveness of the DS-eVUE control system as well as the dual-strand Y-tooling, accuracy of product dimensionality, cut quality, cooling tank capabilities, and the ability to isolate products with castoff equipment. In addition, Intralox was able to witness and approve the entire operating line at Conair, Davis-Standard’s downstream equipment partner. This run-off provided valuable insight into Davis-Standard’s ability to customize the line to meet current and future expectations.

“Intralox ships product all over the world to support customers in the automotive, food, industrial, logistics and material handling, packaging, tire and rubber industries,” said Sean Stephan, Davis-Standard’s regional manager responsible for this project. “Being able to take their outputs from 125 feet per minute to 300 feet per minute on the same line while supporting quality goals really defined this project. Their continued growth and leadership in conveyor systems is testament to their excellence as a company. We are proud to be their extrusion equipment supplier and look forward to our continued work with them.”

For more information about Intralox, visit www.intralox.com. For more information about Davis-Standard’s pipe, profile and tubing solutions, visit www.davis-standard.com/extrusion_system/pipe-profile-and-tubing/.

Robert Ackley made history with a storied 46-year career at Davis-Standard. Most recently, he added another achievement to his remarkable journey by becoming a plastics industry “hall of famer.” Ackley was welcomed into the Plastics Hall of Fame at a formal ceremony during the National Plastics Exposition (NPE) in Orlando, Fla. on May 6. With his induction, Ackley joins the ranks of the industry’s most notable pioneers and leaders.

Robert Ackley made history with a storied 46-year career at Davis-Standard. Most recently, he added another achievement to his remarkable journey by becoming a plastics industry “hall of famer.” Ackley was welcomed into the Plastics Hall of Fame at a formal ceremony during the National Plastics Exposition (NPE) in Orlando, Fla. on May 6. With his induction, Ackley joins the ranks of the industry’s most notable pioneers and leaders.

“My time in the plastics machinery business has been fun. I took advantage of being brought up on a potato farm. My father preached that work was good for a person and hard work was even better,” Ackley explained during his acceptance speech. “My 46 years with Davis-Standard in the plastics industry were very enjoyable. It never felt like hard work, but more like an adventure.”

Ackley’s story embodies the American Dream. He started as a draftsman fresh out of high school, low man on the totem pole. He attended college at night eventually earning his degree in mechanical engineering from Mitchell College, followed by an executive MBA from the University of New Haven. Through diligence, hard work and company loyalty, Ackley worked his way up the ranks through engineering, field services, sales and spare parts, to become company president; a position he held for 22 years. During his tenure, he saw the company grow from fewer than 75 employees, a limited equipment portfolio and 3 million in sales, to a global powerhouse serving every major industry. When Ackley retired in 2005, Davis-Standard employed 1,000 and sales were over $300 million.

The cornerstone of his success? Those who have supported him along the way. “My Davis-Standard colleagues have greatly contributed to any success I’ve had, and I am grateful to them for putting my name forward for this recognition. I’ve also had the benefit of an amazing family, three kids and grandkids, and my terrific wife Elaine who has been at my side for 56 years,” he said. “To be included with others who have done so much to advance the industry is a great honor and quite humbling.”

For those at Davis-Standard now, the name Ackley will forever be tantamount to the company’s long-standing reputation for quality, industry leadership and exceptional service. All of it homegrown right here in the Stonington-Pawcatuck area by the son of a potato farmer.

For more information about Davis-Standard, visit www.davis-standard.com.