Davis-Standard, LLC will promote the company’s equipment innovation and regional growth at Hall 9.2, Booth J41, during CHINAPLAS 2019 in Guangzhou, May 21-24, alongside its subsidiaries Maillefer and Brampton Engineering. Davis-Standard will share information about its recent acquisitions, Suzhou facility expansion, DS Activ-Check system for continuous extruder monitoring, dsX flex-pack™ technology and stretch film capabilities. Davis-Standard will also exhibit a HPE-100H, 1” 24:1 extruder.

The acquisition of Brampton in 2018 augmented the company’s multi-layer film processing and winding technology for blown film applications. TSL (Thermoforming Systems LLC), also added in 2018, is the market leader in thermoforming equipment for high-volume packaging applications. TSL fits nicely with Davis-Standard’s continued growth in the packaging sector. Maillefer, acquired in 2017, expanded the company’s wire and cable, pipe and tube equipment offering, and added facilities in Finland and Switzerland to better serve customers, including those in China.

Davis-Standard’s Suzhou location is expanding this year. The additional 35,000 square-foot (3,251 square-meter) facility near the existing shop in Suzhou will house control panel assembly and provide much-needed warehousing. The addition reflects Davis-Standard’s strong extrusion coating business and long-term strategy in the region. Suzhou is also home to an R&D laboratory that supports Asia’s medical market. This capability has been an asset to customers, and an excellent tool for supporting development of new resins and biodegradable products.

In response to the increased demand for “smart” technology, Davis-Standard recently introduced the DS Activ-Check system for continuous extruder monitoring. DS Activ-Check enables processors to take advantage of real-time preventative maintenance by providing early notifications of potential extruder failures. Machine operators are alerted to issues before they happen, preventing unnecessary downtime while also collecting valuable data. Key parameters monitored include extruder reducer, lubrication system, motor characteristics, the drive power unit, barrel heating and cooling.

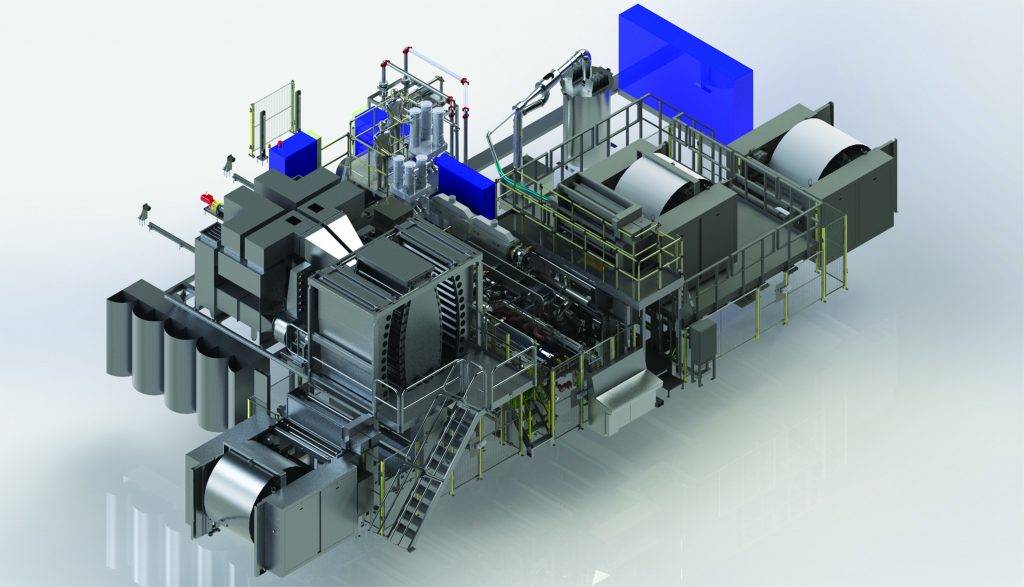

The latest dsX flex-pack™ model being promoted is the 300S. This single station extrusion and laminating line is designed specifically for the Asian flexible packaging market. It is a collaboration among Davis-Standard’s teams in the U.S., Germany and China, addressing the pricing, machine footprint, speeds and output, and shorter runs demanded by converters. Davis-Standard is also engineering a tandem configuration of this machine called the dsX flex-pack™ 300T. The dsX flex-pack™ 300S will be available for demonstration in Suzhou later this year.

For stretch film applications, Davis-Standard offers a stretch film line equipped with a DS S3 winder. The line offers a compact machine arrangement, ease of servicing, excellent profile control, consistent roll quality and an intuitive control package. It is engineered for producing thin films from 31-to 51-gauge (7.8µ to 13µ) at high speeds. The side-by-side DS S3 overlapping winder is essential to this capability, enabling maximum slit widths for hand-wrap, machine-wrap and jumbo rolls. This winder also makes it possible for converters to support multiple market segments on one winder.

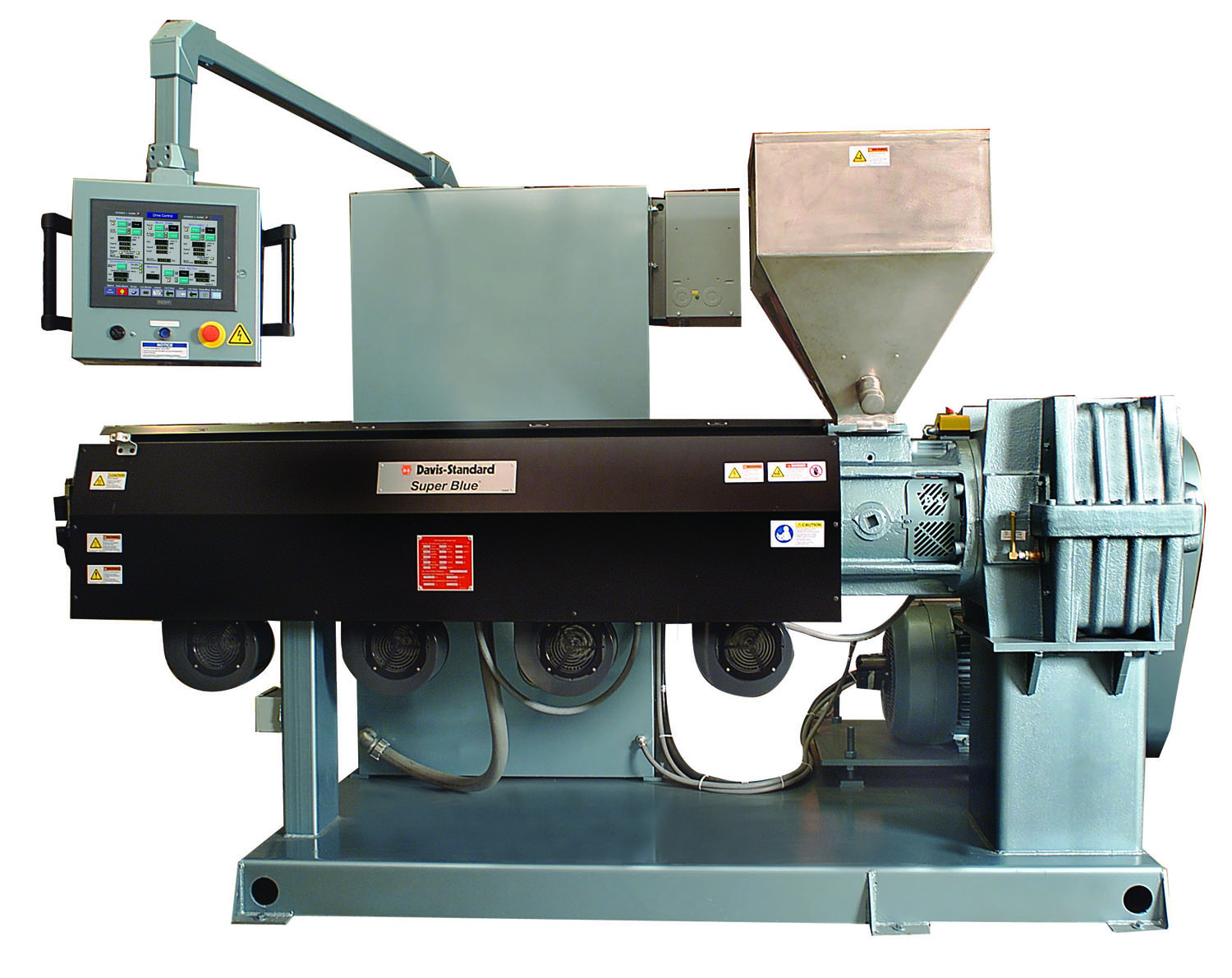

The HPE-100H extruder being shown is an example of Davis-Standard’s performance engineering for versatility, long-term market value and an attractive return on investment. This extruder is designed for co-extrusion and multi-layer applications, and is available with a variety of DSB® feedscrew designs depending on the application. Advantages include a small footprint, high-torque capacity to handle a variety of resins and a direct coupled motor. Models are available in ¾-inch (20mm) to 1.75 (45mm) inches with L/D’s in 24:1 or 30:1. For added support, the extruder comes with a three-year warranty.

For more information about Davis-Standard prior to Chinaplas, visit www.davis-standard.com.

PHOTO CAPTION: Pictured is the dsX flex-pack™300S.

In only two years since installing a seven-layer Davis-Standard blown film line, Rani Plast of Finland is experiencing profitable outcomes for its agricultural film operation. Since the line’s start-up in August of 2016, Rani Plast has expanded its family-run business by optimizing production, developing its distributor network and introducing new products. At the time of installation, this was the largest seven-layer blown film line Davis-Standard had ever built for a customer.

In only two years since installing a seven-layer Davis-Standard blown film line, Rani Plast of Finland is experiencing profitable outcomes for its agricultural film operation. Since the line’s start-up in August of 2016, Rani Plast has expanded its family-run business by optimizing production, developing its distributor network and introducing new products. At the time of installation, this was the largest seven-layer blown film line Davis-Standard had ever built for a customer.

Davis-Standard’s converting technology and support services will be promoted at ICE USA, booth #619, in Lousiville, Kentucky April 9-11, 2019. Davis-Standard will highlight key equipment capabilities for extrusion coating, liquid coating, blown film and cast film, all engineered to support a range of applications on every continent. Davis-Standard will also have information on aftermarket and technical services focused on delivering cost-efficiency, reduced downtime and improved operation. This includes equipment upgrades, replacement parts, global field services, custom engineering, research and technical services, and a 24/7 customer service hotline. Following is a summary of key technologies in Davis-Standard’s product portfolio.

Davis-Standard’s converting technology and support services will be promoted at ICE USA, booth #619, in Lousiville, Kentucky April 9-11, 2019. Davis-Standard will highlight key equipment capabilities for extrusion coating, liquid coating, blown film and cast film, all engineered to support a range of applications on every continent. Davis-Standard will also have information on aftermarket and technical services focused on delivering cost-efficiency, reduced downtime and improved operation. This includes equipment upgrades, replacement parts, global field services, custom engineering, research and technical services, and a 24/7 customer service hotline. Following is a summary of key technologies in Davis-Standard’s product portfolio. Davis-Standard’s technology and support services will be promoted at Plasticos Brazil, Hall D, booth 142 in Sao Paulo, Brazil, March 25-29, 2019. Davis-Standard will highlight key equipment capabilities for extrusion coating, blown film, cast film, sheet extrusion and thermoforming, all engineered to support a range of applications on every continent. Davis-Standard will also have information on aftermarket and technical services focused on delivering cost-efficiency, reduced downtime and improved operation. This includes equipment upgrades, replacement parts, global field services, custom engineering, research and technical services, and a 24/7 customer service hotline. Following is a summary of key technologies in Davis-Standard’s product portfolio. The company’s extrusion coating product line is a comprehensive equipment offering from a single-source supplier to address basic applications all the way up to high-speed, complex requirements. Systems are engineered for everything from high-quality flexible packaging, thermal lamination and stand-up pouches, to lidding, tube, and aseptic films. Specifications can be customized based on market requirements and investment plans.

Davis-Standard’s technology and support services will be promoted at Plasticos Brazil, Hall D, booth 142 in Sao Paulo, Brazil, March 25-29, 2019. Davis-Standard will highlight key equipment capabilities for extrusion coating, blown film, cast film, sheet extrusion and thermoforming, all engineered to support a range of applications on every continent. Davis-Standard will also have information on aftermarket and technical services focused on delivering cost-efficiency, reduced downtime and improved operation. This includes equipment upgrades, replacement parts, global field services, custom engineering, research and technical services, and a 24/7 customer service hotline. Following is a summary of key technologies in Davis-Standard’s product portfolio. The company’s extrusion coating product line is a comprehensive equipment offering from a single-source supplier to address basic applications all the way up to high-speed, complex requirements. Systems are engineered for everything from high-quality flexible packaging, thermal lamination and stand-up pouches, to lidding, tube, and aseptic films. Specifications can be customized based on market requirements and investment plans. Davis-Standard is pleased to announce that Jay Totten has joined the company as regional account manager for converting systems, extrusion and liquid coating, serving the Midwest region. Totten will be responsible for capital equipment sales in Illinois, Indiana, Iowa, Minnesota and Wisconsin. He brings a wealth of knowledge, having previously worked at BOBST as a sales manager. Totten also has prior experience with ConQuip, Inc., Faustel, Inc. and Bostik Findley, Inc., giving him a well-rounded industry background. He is active in the Association of International Metallizers, Coaters and Laminators (AIMCAL) as a member of a technical committee.

Davis-Standard is pleased to announce that Jay Totten has joined the company as regional account manager for converting systems, extrusion and liquid coating, serving the Midwest region. Totten will be responsible for capital equipment sales in Illinois, Indiana, Iowa, Minnesota and Wisconsin. He brings a wealth of knowledge, having previously worked at BOBST as a sales manager. Totten also has prior experience with ConQuip, Inc., Faustel, Inc. and Bostik Findley, Inc., giving him a well-rounded industry background. He is active in the Association of International Metallizers, Coaters and Laminators (AIMCAL) as a member of a technical committee. Davis-Standard’s converting technology and support services will be promoted at ICE Europe, Hall A5, booth #1310, in Munich, Germany, March 12-14, 2019. Davis-Standard will highlight key equipment capabilities for extrusion coating, liquid coating, blown film and cast film, all engineered to support a range of applications on every continent. Davis-Standard will also have information on aftermarket and technical services focused on delivering cost-efficiency, reduced downtime and improved operation. This includes equipment upgrades, replacement parts, global field services, custom engineering, research and technical services, and a 24/7 customer service hotline. Following is a summary of key technologies in Davis-Standard’s product portfolio.

Davis-Standard’s converting technology and support services will be promoted at ICE Europe, Hall A5, booth #1310, in Munich, Germany, March 12-14, 2019. Davis-Standard will highlight key equipment capabilities for extrusion coating, liquid coating, blown film and cast film, all engineered to support a range of applications on every continent. Davis-Standard will also have information on aftermarket and technical services focused on delivering cost-efficiency, reduced downtime and improved operation. This includes equipment upgrades, replacement parts, global field services, custom engineering, research and technical services, and a 24/7 customer service hotline. Following is a summary of key technologies in Davis-Standard’s product portfolio.