ENGICCS to Represent Davis-Standard in West Africa

Davis-Standard is pleased to announce that Engineering Customer Centric Solutions (ENGICCS) Ltd. is the company’s new sales representative in West Africa. ENGICCS is a global player in the design, development and distribution of innovative solutions for packaging film, polymer electronics and converting systems. As Davis-Standard’s representative, they will be responsible for facilitating direct contact with plastics converters and stakeholders in West Africa to identify converting needs and market plastic packaging solutions throughout the region.

Davis-Standard is pleased to announce that Engineering Customer Centric Solutions (ENGICCS) Ltd. is the company’s new sales representative in West Africa. ENGICCS is a global player in the design, development and distribution of innovative solutions for packaging film, polymer electronics and converting systems. As Davis-Standard’s representative, they will be responsible for facilitating direct contact with plastics converters and stakeholders in West Africa to identify converting needs and market plastic packaging solutions throughout the region.

According to Dr. Anye Chifen, Managing Director of ENGICCS, “We look forward to increasing awareness of the Davis-Standard brand through strategic marketing avenues, while also providing more facetime with customers. A key part of our role in this region is to cultivate long-term partnerships and offer value-added solutions. This is an important step in gaining a greater understanding of customer needs and providing outstanding solutions to the industry.”

Davis-Standard recently participated in the Nigeria Plastprintpack + Agro Food Exhibition in late March. The exhibition proved to be a timely opportunity to discuss Davis-Standard’s solutions in flexible packaging and to learn more about Nigerian-based manufacturing companies. According to the National Agency for Food and Drug Administration and Control (NAFDAC) in Nigeria, the country’s plastic and packaging sector has experienced substantial growth in recent decades from around 50 companies in the 1960’s to more than 3,000 manufacturers today. Based on feedback from the show, Davis-Standard looks forward to supporting Nigeria’s rapidly growing converting and extrusion markets, specifically in the area of packaging films.

For more information about ENGICCS, visit www.engiccs.com. For more information about Davis-Standard, visit www.davis-standard.com.

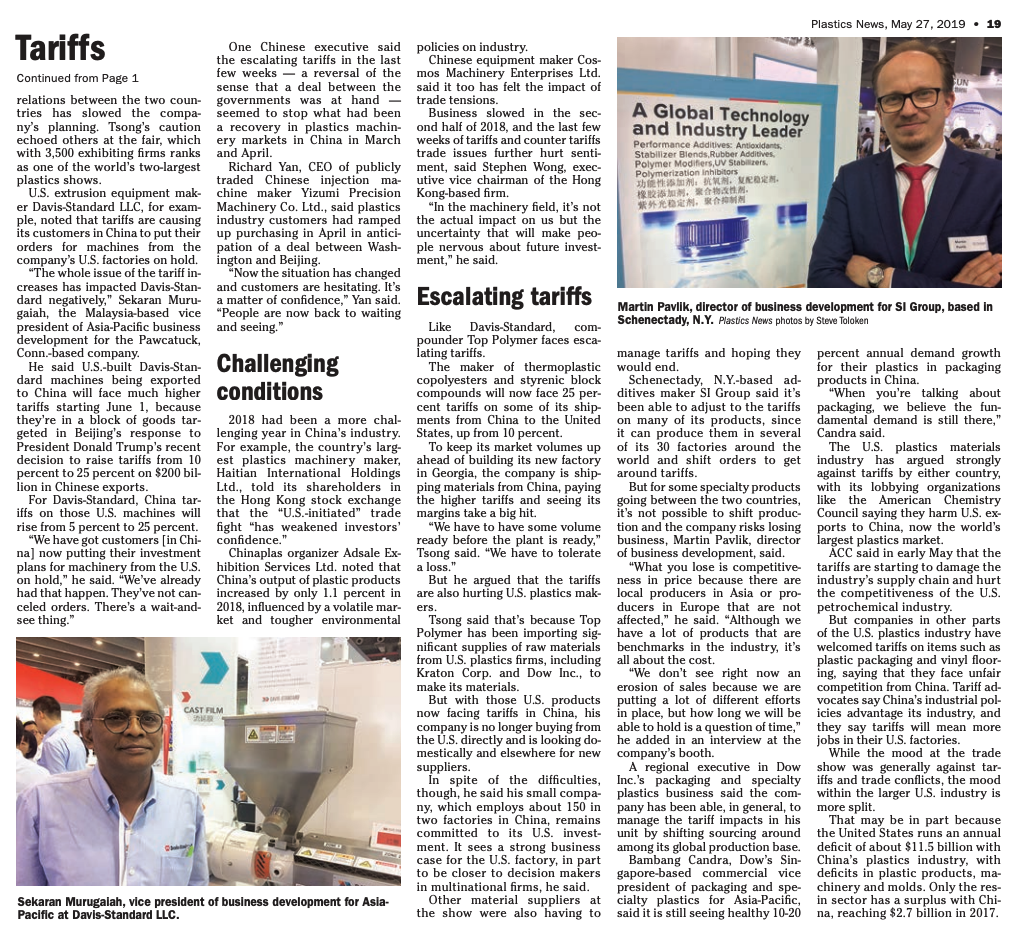

Plastics News: Escalating tariffs signal caution for Chinaplas investments

Flexible Packaging Magazine: Roundtable of Extrusion Equipment

Davis-Standard’s N.Y. Facility Celebrates 365 Days Injury-Free

Davis-Standard is pleased to announce the company’s manufacturing facility in Fulton, N.Y., recently celebrated 365 days without a lost time accident or OSHA recordable injury. This is a tremendous milestone credited to Davis-Standard’s high standards and safety practices for all employees. Dan Guthrie, Davis-Standard COO, said that attention to work area details, participation in safety training meetings, weekly area inspections, sharing toolbox talk points and a holistic team approach to improve safety for all site employees was key to reaching this milestone.

“Maintaining an injury-free workplace at all of our locations is our first initiative and top priority,” said Guthrie. “This milestone at our plant in New York is significant in achieving this objective. I commend our employees as this is not easy to do, even when you have standards of excellence in place. We look forward to celebrating this milestone at every Davis-Standard manufacturing facility worldwide.”

Photo Caption: Fulton, N.Y. operating team

Davis-Standard Launches 844-MYDAVIS for Service Queries

Davis-Standard is pleased to announce customers worldwide can now take advantage of a new 24/7 First Responder phone number 844-MYDAVIS (844-693-2847). This central point of contact reflects Davis-Standard’s continued commitment to Comprehensive 360 Support of our global customers with technical, personalized and timely responses to all service inquiries. By calling this number, customers can reach our global support centers 24 hours a day to identify and quickly facilitate their requests. In addition, translation services are available in English, German, French, Spanish, Finnish and Mandarin.

Davis-Standard is pleased to announce customers worldwide can now take advantage of a new 24/7 First Responder phone number 844-MYDAVIS (844-693-2847). This central point of contact reflects Davis-Standard’s continued commitment to Comprehensive 360 Support of our global customers with technical, personalized and timely responses to all service inquiries. By calling this number, customers can reach our global support centers 24 hours a day to identify and quickly facilitate their requests. In addition, translation services are available in English, German, French, Spanish, Finnish and Mandarin.

“Implementing 844-MYDAVIS is an important step in supporting our global customers with the sense of urgency needed to keep their production schedules without delay,” said Jim Murphy, President and CEO of Davis-Standard. “Keeping up with our new brand standard, we are leading the way in providing solutions to support our customers’ uptime and competitiveness. The bottom line is, the customer wants to talk to the right person right away. We anticipate the addition of the 24/7 First Responder number (844-MYDAVIS) moves us closer to achieving that goal.”

For more information about Davis-Standard’s service capabilities, visit www.davis-standard.com/service-support/overview/.

Canadian Plastics Magazine: Get Smart

Davis-Standard’s Subsidiary in Suzhou Adds Manufacturing Space

Davis-Standard (Suzhou) Plastics Packaging Machinery Co., Ltd. is pleased to announce the expansion of the company’s manufacturing capabilities. Open for operation at the end of April 2019 is an additional 35,000 square-foot (3,251 square-meter) facility near the existing shop in Suzhou and will house control panel assembly and provided much-needed warehousing. The addition reflects Davis-Standard’s growing extrusion coating business and long-term strategy in the region.

Davis-Standard (Suzhou) Plastics Packaging Machinery Co., Ltd. is pleased to announce the expansion of the company’s manufacturing capabilities. Open for operation at the end of April 2019 is an additional 35,000 square-foot (3,251 square-meter) facility near the existing shop in Suzhou and will house control panel assembly and provided much-needed warehousing. The addition reflects Davis-Standard’s growing extrusion coating business and long-term strategy in the region.

“The additional space will allow us to build more extrusion coating lines at our main plant while supporting other machine services, including faster delivery,” said Jinsong Lin, general manager at Suzhou. “We also appreciate how close this building is to our existing facility. The increased manufacturing capacity is a positive reflection of our growth over the past few years. We have become one of the top equipment suppliers in the region and we don’t take that for granted.”

The medical tubing and packaging segments continue to be strong markets for Davis-Standard throughout Asia. Equipment sold to regional customers for medical tubing, extrusion coating and co-extrusion applications is built in Suzhou, as is assembly of electrical control panels, extruders and gearcases. There is also an impressive R&D facility at this location, equipped with technology for testing a range of rigid and flexible products, as well as FPVC tubing for IV and fluid delivery. Examples include microbore tubing, multi-lumen and catheter tubing, endotracheal and tracheotomy tubing, bubble tubing, taper tubing and others. Most recently, Davis-Standard added a new dsX flex-pack™ 300S to this lab for customer trials. This is a single station extrusion and lamination line built specifically for the Asian flexible packaging market.

For more information about Davis-Standard’s subsidiary in Suzhou, visit www.davis-standard.com.cn

Rubber World Magazine: Elastomer Technology from Davis-Standard Embraces Industry Trends

Davis-Standard’s Regional Expertise at Chinaplas 2019

Davis-Standard, LLC will promote the company’s equipment innovation and regional growth at Hall 9.2, Booth J41, during CHINAPLAS 2019 in Guangzhou, May 21-24, alongside its subsidiaries Maillefer and Brampton Engineering. Davis-Standard will share information about its recent acquisitions, Suzhou facility expansion, DS Activ-Check system for continuous extruder monitoring, dsX flex-pack™ technology and stretch film capabilities. Davis-Standard will also exhibit a HPE-100H, 1” 24:1 extruder.

The acquisition of Brampton in 2018 augmented the company’s multi-layer film processing and winding technology for blown film applications. TSL (Thermoforming Systems LLC), also added in 2018, is the market leader in thermoforming equipment for high-volume packaging applications. TSL fits nicely with Davis-Standard’s continued growth in the packaging sector. Maillefer, acquired in 2017, expanded the company’s wire and cable, pipe and tube equipment offering, and added facilities in Finland and Switzerland to better serve customers, including those in China.

Davis-Standard’s Suzhou location is expanding this year. The additional 35,000 square-foot (3,251 square-meter) facility near the existing shop in Suzhou will house control panel assembly and provide much-needed warehousing. The addition reflects Davis-Standard’s strong extrusion coating business and long-term strategy in the region. Suzhou is also home to an R&D laboratory that supports Asia’s medical market. This capability has been an asset to customers, and an excellent tool for supporting development of new resins and biodegradable products.

In response to the increased demand for “smart” technology, Davis-Standard recently introduced the DS Activ-Check system for continuous extruder monitoring. DS Activ-Check enables processors to take advantage of real-time preventative maintenance by providing early notifications of potential extruder failures. Machine operators are alerted to issues before they happen, preventing unnecessary downtime while also collecting valuable data. Key parameters monitored include extruder reducer, lubrication system, motor characteristics, the drive power unit, barrel heating and cooling.

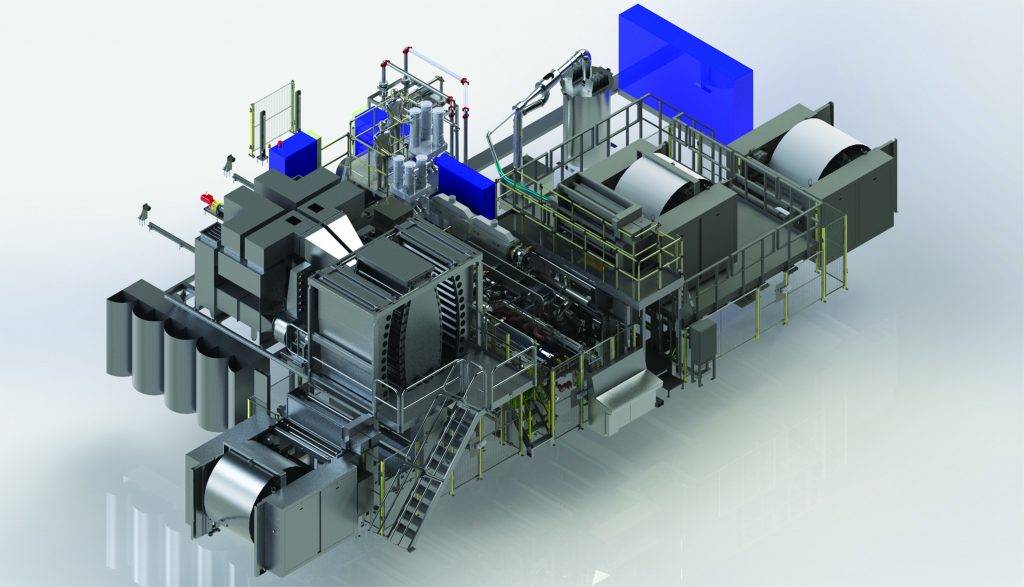

The latest dsX flex-pack™ model being promoted is the 300S. This single station extrusion and laminating line is designed specifically for the Asian flexible packaging market. It is a collaboration among Davis-Standard’s teams in the U.S., Germany and China, addressing the pricing, machine footprint, speeds and output, and shorter runs demanded by converters. Davis-Standard is also engineering a tandem configuration of this machine called the dsX flex-pack™ 300T. The dsX flex-pack™ 300S will be available for demonstration in Suzhou later this year.

For stretch film applications, Davis-Standard offers a stretch film line equipped with a DS S3 winder. The line offers a compact machine arrangement, ease of servicing, excellent profile control, consistent roll quality and an intuitive control package. It is engineered for producing thin films from 31-to 51-gauge (7.8µ to 13µ) at high speeds. The side-by-side DS S3 overlapping winder is essential to this capability, enabling maximum slit widths for hand-wrap, machine-wrap and jumbo rolls. This winder also makes it possible for converters to support multiple market segments on one winder.

The HPE-100H extruder being shown is an example of Davis-Standard’s performance engineering for versatility, long-term market value and an attractive return on investment. This extruder is designed for co-extrusion and multi-layer applications, and is available with a variety of DSB® feedscrew designs depending on the application. Advantages include a small footprint, high-torque capacity to handle a variety of resins and a direct coupled motor. Models are available in ¾-inch (20mm) to 1.75 (45mm) inches with L/D’s in 24:1 or 30:1. For added support, the extruder comes with a three-year warranty.

For more information about Davis-Standard prior to Chinaplas, visit www.davis-standard.com.

PHOTO CAPTION: Pictured is the dsX flex-pack™300S.