Recent News

Past News

Davis-Standard is pleased to announce that four children of Davis-Standard employees recently earned scholarships through the Wire and Cable Industry Suppliers Association (WCISA). The organization awarded a total of 10 scholarships worth over $3,000 in a competitive field of applicants. The four Davis-Standard students honored were Abel Keeley, Abigail Christman, Camille Stevenson and Nadine Dickter. Following is background on each.

Davis-Standard is pleased to announce that four children of Davis-Standard employees recently earned scholarships through the Wire and Cable Industry Suppliers Association (WCISA). The organization awarded a total of 10 scholarships worth over $3,000 in a competitive field of applicants. The four Davis-Standard students honored were Abel Keeley, Abigail Christman, Camille Stevenson and Nadine Dickter. Following is background on each.

Abel Keeley, a National Merit Finalist, is attending the Rose-Hulman Institute of Technology in Terre Haute, Indiana. He is studying electrical engineering with a focus on medical, military and consumer applications. Keeley has always been drawn to engineering, successfully building a custom computer in ninth grade. He is interested in designing improved safety systems and devices that support day-to-day activities for persons with disabilities, and systems to help businesses improve efficiencies.

Abigail Christman is attending the University of Pittsburgh in Pittsburgh, Pennsylvania, where she is studying chemistry and pharmacy. Christman graduated in the top five percent of her high school class and was very involved with marching band, YMCA, school organizations and clubs. She has continued her involvement with music as a member of Pittsburgh’s marching band. Her goal is to one day work in a hospital setting with pediatric patients.

Camille Stevenson is studying neuroscience at the University of Rochester in Rochester, New York. She was valedictorian of her class, a three-sport athlete, musician and leader in several school clubs and organizations. Stevenson is a firm believer in community involvement and transformative leadership. This has led to her career goal of becoming a neurodegenerative researcher to support those with diseases such as Alzheimer’s and Parkinson’s.

Nadine Dickter is a junior at Hobart and William Smith Colleges in Geneva, New York, where she is pursuing a degree in chemistry and minor in public policy and women’s studies. Dickter worked in the engineering and manufacturing industry over the summer, providing greater insight into the daily application and role of chemistry in the workplace. Upon graduation, she plans to attend graduate school and achieve a Ph.D. in chemistry and work in the extrusion industry.

“We are very proud of each of these students; their accomplishments and aspirations,” said John Zachow, Davis-Standard’s Vice President of Wire and Cable and WCISA member. “They are part of our Davis-Standard family, and we’ve had the privilege of watching them grow into successful adults. We’re excited about their futures and the impact they will make within their chosen career fields.”

WCISA is a nonprofit corporate membership association with over 100 North American suppliers of machinery, materials and accessories used for making all types of wire and cable. Members are based in or have an established subsidiary in North America. WCISA’s mission is to promote its members’ products and services by providing its members with representation, networking, social opportunities and services at wire and cable trade events and conferences.

For more information about WCISA, visit wcisaonline.org. For more information about Davis-Standard, visit www.davis-standard.com.

Davis-Standard’s German subsidiary ER-WE-PA GmbH is pleased to announce its “Fit-4-Future” alignment to better support customers worldwide. Under this structure, ER-WE-PA will focus on being the product line leader for aseptic packaging machinery within the Davis-Standard organization, while also offering winding systems (winding and unwinding), liquid and adhesive coating systems and aftermarket capabilities. This will enable the company to leverage global resources and product expertise offered by Davis-Standard’s global network while providing innovative solutions that support customer growth.

“The converting side of the business has always been a strength at ER-WE-PA,” said Michael Krämer, Managing Director at ER-WE-PA GmbH. “By focusing on these areas, we can take advantage of proven technologies while also ensuring regionalized access to Davis-Standard aftermarket and support resources. We are also equipped with an excellent leadership team to deliver results.”

Below you will find the new contacts according to the new structure:

Michael Krämer – Managing Director

Michael Krämer has been Managing Director of ER-WE-PA GmbH since January 1, 2019. His plastics industry leadership in the U.S. and Germany has delivered global prospects and valuable knowledge.

André Schlapp - Head of Operations

With more than 30 years of experience at ER-WE-PA. André Schlapp is now responsible for engineering, procurement and after-sales services.

Michael Schröder - Head of Sales / Product and Project Management

Michael Schröder is responsible for sales in Europe, the Middle East and Africa, as well as product and project management. He has more than 43 years of professional experience in extrusion machinery at ER-WE-PA.

André Warth - Area Sales Manager, Europe

André Warth is responsible for sales in Europe. He has more than 23 years of experience in the distribution of beverage carton packaging systems.

For more information, visit www.davis-standard.com

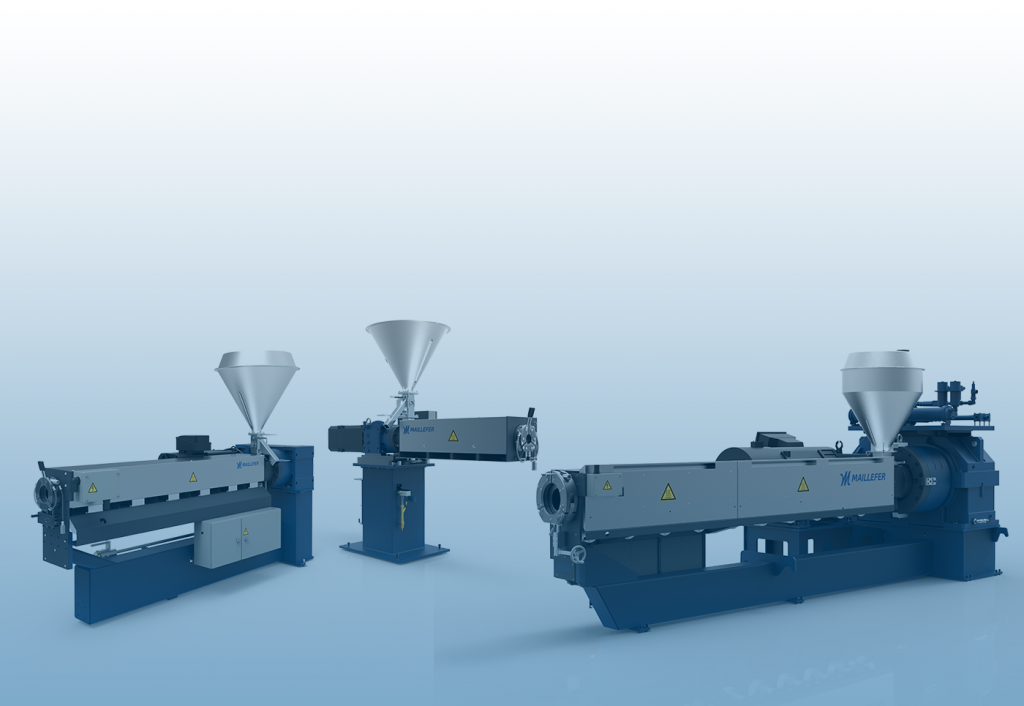

As global demand for medical tubing applications continues to grow and technology requirements evolve, Davis-Standard offers processors some of the industry’s most robust and reliable equipment options. This is supported by a comprehensive approach whereby every extruder and every system is backed by in-house R&D and responsive customer service. This includes technology from Maillefer, A Davis-Standard Company, and global support from Davis-Standard subsidiaries such as Davis-Standard (Suzhou) Plastics Packaging Machinery Co, Ltd.

As global demand for medical tubing applications continues to grow and technology requirements evolve, Davis-Standard offers processors some of the industry’s most robust and reliable equipment options. This is supported by a comprehensive approach whereby every extruder and every system is backed by in-house R&D and responsive customer service. This includes technology from Maillefer, A Davis-Standard Company, and global support from Davis-Standard subsidiaries such as Davis-Standard (Suzhou) Plastics Packaging Machinery Co, Ltd.

Davis-Standard supplies medical tubing systems with extruder output ranging up to 600 pounds per hour and line speeds up to 900 feet per minute (275 mpm) for numerous materials including FPVC, polyurethane, nylon, PEBAX and FEP. Applications include microbore tubing, Alternate Polymer®, multi-lumen catheter tubing, endotracheal and tracheotomy tubing, Radiopaque striped tubing, fluid delivery and drainage tubing, bubble tube with funnel, taper tube, cannula tube, pipette tube and multi-layer tubing among others

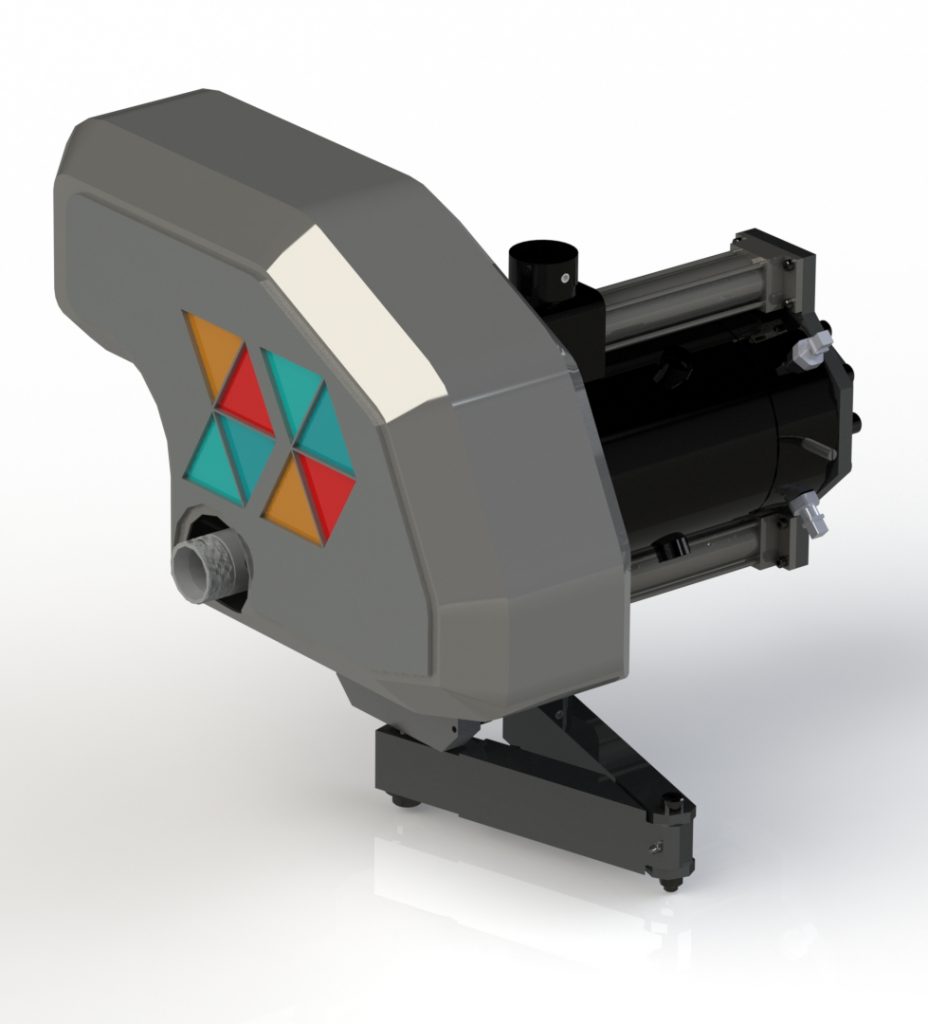

Maillefer also offers single-layer soft PVC tubing lines as well as medical fluoropolymer lines. High-speed extrusion for soft PVC medical tubes is engineered for various grades of medical PVC and for dimensional stability of tubes. Customized lines for FEP tubing and special polymers give processors ample options regardless of application. Maillefer also offers a coiler, the KWA, for medical tube winding applications. This fully-automated coiler is designed for performance, precision and cleanliness. The unit, which features precision machined parts and two stainless steel turrets keeps pace with lines running at speeds over 900 feet per minute (275 mpm). It can wind medical tubing into coils up to 24 inches (620mm) in diameter.

Davis-Standard medical tubing systems are built around high-performance extruders. These include:

The MEDD Extruder –The small-footprint, direct-drive MEDD offers versatile capabilities for a full range of product development. It is available in sizes ¾-inch (19mm) and 1-inch (25mm) and uses a direct drive motor, no gear box for clean room applications. Other advantages include interchangeable barrel assemblies, linear machine movement and a replaceable feed section liner.

HPE-A and HPE-H Extruder – These extruders, available in ¾-inch (19mm) to 1 ¾-inch (44mm) also feature a small footprint. The A (adjustable) model uses a direct couple motor and the extruder swivels on a column to enable positioning at any angle. Vertical adjustment is possible by means of a lift screw. The H model has a fixed horizontal centerline and both models offer increased torque capacity to handle high-viscosity resins.

The Super Blue® is available from 2 inches (50mm) up to 4 ½ inches (114mm). Advantages include double-reduction gearboxes with helical carburized gears, an integral high capacity thrust bearing, integrated control cabinet and the DSBM-T™ barrier mixing feedscrew. It is also pre-engineered for fast delivery. To further support precision extrusion, processors can add a melt pump to these extruders. The Davis-Standard melt pump features a precision AC vector or servo drive system; precision gear reducer and drive motor.

Davis-Standard offers processors the unique option of testing equipment prior to purchase. The company’s Technical Center in Pawcatuck, Conn., is equipped with numerous extruders, as well as an R&D line in a cleanroom environment for end-product development of tight tolerance tubing. Customers can test new resins, make parts for proof-of-concept, and conduct downstream R&D. The line, which is in a dedicated, climate-controlled area, is equipped with two MEDD extruders as well as Davis-Standard’s patented Alternate Polymer® process technology and EPIC III® control system.

The R&D lab in Suzhou features a multipurpose microbore tubing line for medical application trials and development. It is engineered for single or dual-layer tubing as well as single-lumen tubing with or without a stripe. The line is equipped with two extruders, an OD/ID wall thickness measuring and controlling system, closed-loop control via a vacuum sizing tank and puller, and a high-level central control system.

As with every Davis-Standard product line, medical tubing customers can take advantage of 24/7 emergency support, equipment upgrades, expedient spare parts delivery and on-site support.

To find out more about how Davis-Standard can support your medical tubing applications, visit https://davis-standard.com/extrusion_system/pipe-profile-and-tubing/.

Photo Caption: HPE Medical Series 38mm & 25mm extruders for multi-layer tubing applications. Independent touch-screen controls and modular base permit extruders to be relocated as required to alternate extrusion lines to integrate with in-line or cross-head tooling applications.

Davis-Standard will be among more than 200 companies at the upcoming Rubber Expo, October 7-10, in Cleveland, Ohio. Davis-Standard, Booth #1210, will promote extrusion equipment, feedscrews and controls as well as the company’s DSREV extruder, Model 3000 crosshead and Uth roll-ex® 70 gear pump/strainer system with two-roll feeder (TRF). An aftermarket representative will be available to discuss feedscrew services, spare parts, extruder rebuilds, process control upgrades and other options for improved processing. In addition, Davis-Standard will discuss the technical cell at its facility in Pawcatuck to support R&D for hose, automotive seals and architectural applications as well as processes requiring in-line straining and pressure stabilization.

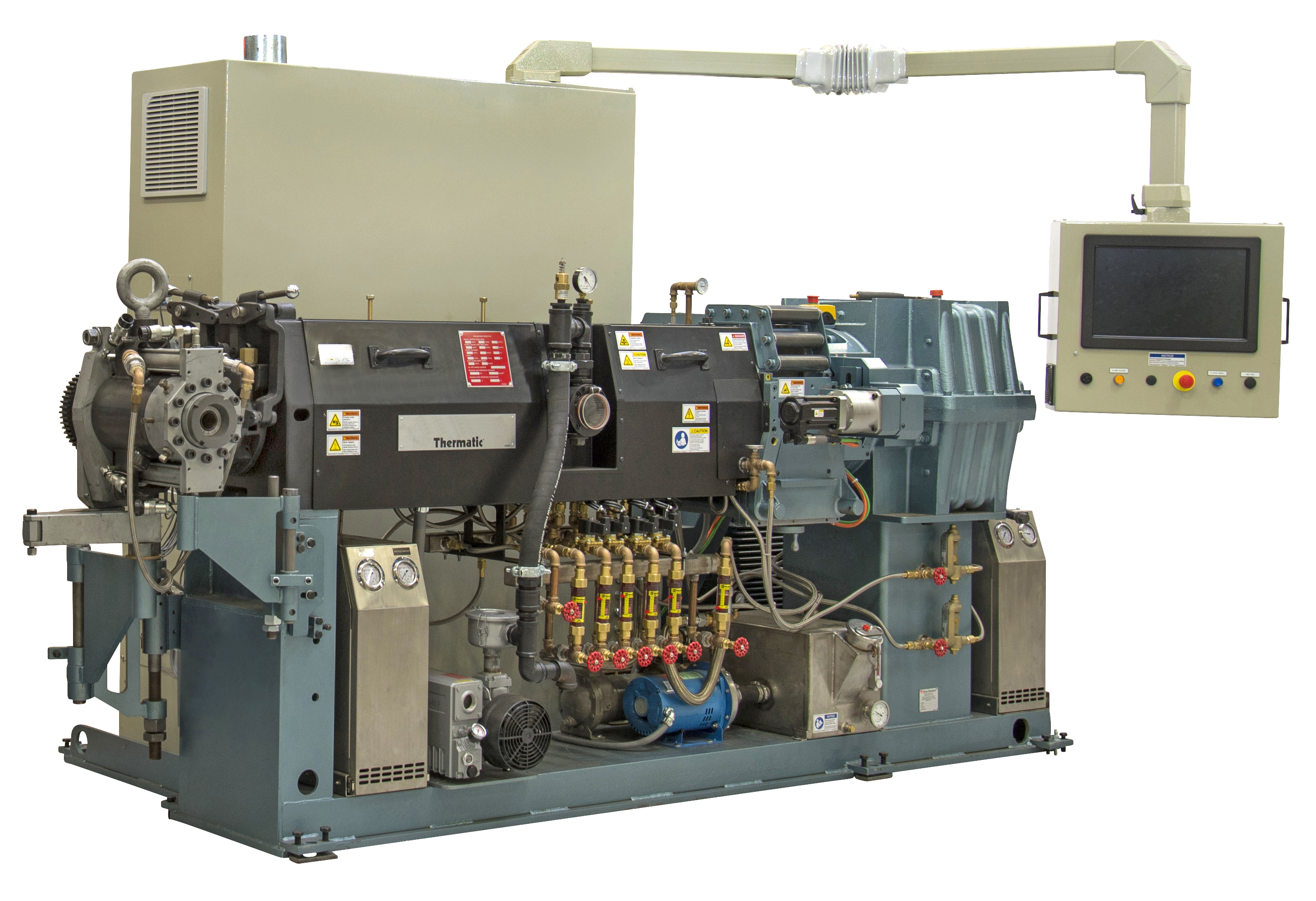

The DSREV extruder is Davis-Standard’s flagship design. It is a preconfigured machine with feedscrew and head zone direct-injection temperature control units, a compact base, and simplified cooling and wiring systems. Other advantages include touch-screen controls, process data acquisition, and easily accessible machine components. The Model 3000 hydraulic crosshead reduces scrap and enables faster start-up times. This crosshead offers preferred features such as a tapered mandrel and highly engineered flow paths to ensure consistent flow through all speed ranges, as well as a thrust bearing on pin adjustment to adjust wall thickness without interruption.

When this technology is coupled with the Uth gear pump, processors can isolate high pressure and achieve pressure stabilization. The gear pump is equipped with a Uth two-roll feeder (TRF) to be used as a stand-alone device for fine mesh straining or for cold feeding. Other advantages include improved filtration, reduced material retention time and a small footprint for easy integration into existing lines.

For more information prior to the show, contact us or visit https://davis-standard.com/extrusion_system/elastomer/.

Photo Caption: Davis-Standard 3-1/2” 20:1 L/D DSREV (Davis-Standard Rubber Electrically Heated Vented) Multipurpose Extruder shown with our DS-eVUE touch screen process control system. Additional features shown include fully integrated closed-loop cooling system, Servo Driven feed roll option and Model 3000 Crosshead.

Davis-Standard is pleased to introduce the latest option in its award-winning feedscrew line, the DS-Blend. This patent-pending design improves the performance of a single screw extruder for demanding applications by providing distributive and dissipative melt mixing. The two-stage approach achieves outputs similar to those of a single-stage barrier screw, but with a lower melt temperature and reduced energy requirements. It can be installed on new or existing single screw Davis-Standard extruders as well as non-Davis-Standard brands. Building feedscrews for non-Davis-Standard extruders has been a significant area of growth for the company as more and more customers realize the benefits of Davis-Standard feedscrew technology.

According to John Christiano, Vice President of Technology at Davis-Standard, “This is one of our most versatile and energy-efficient feedscrews to date. Customers interested in seeing this design in operation are invited to visit our research and development facility in Pawcatuck.” He added, “As with all of our feedscrew designs, we are focused on product line performance, improved outputs, material homogeneity and feedscrew longevity. We are also proud of the fact that we can build a feedscrew for any extruder brand.”

Davis-Standard’s DSB® feedscrews are the industry standard for design excellence. Feedscrews are available from 3/4 to 12 inches (19 to 300mm) in diameter with varying L/D’s. Each screw is engineered for specific polymers and processes with customization available depending on end product. Davis-Standard feedscrews accommodate the full range of extrusion and converting applications including blown film, blow molding, cast film, compounding, elastomer, extrusion coating, fiber, laboratory, pipe, profile and tubing, reclaim, sheet and specialty systems. Sales and service engineers work alongside customers to find the right solution based on manufacturing parameters. Testing and trials are available to fine-tune the process prior to purchase.

In addition to design, Davis-Standard’s feedscrew manufacturing process reflects quality from start to finish. Plasma arc welding stations provide wear-resistant materials such as Colmonoy 56 and 83. Three state-of-the-art whirlers are used for screw cutting and milling for screws made of stainless steel, 4340 steel or Inconel materials. These machines produce screw surfaces at very tight tolerances. After screws are milled and polished, they are treated with chrome plating or other wear-resistant coatings based on application. Screws receive a final inspection and polish before shipment.

For more information, visit our website: https://davis-standard.com/service-support/parts-and-upgrades.

For inquiries of our feedscrews for Davis-Standard or non-Davis-Standard extruders, please contact us.

Photo caption: DS-Blend Feedscrew.

Davis-Standard will market the company’s extensive line of medical tubing solutions at booth R201 during MedTec China, September 25-27, in Shanghai. This includes complete systems manufactured in the United States, as well as extruders designed in the US and fabricated locally at Davis-Standard’s subsidiary Davis-Standard (Suzhou) Plastic Packaging Machinery Co., Ltd.

Davis-Standard will market the company’s extensive line of medical tubing solutions at booth R201 during MedTec China, September 25-27, in Shanghai. This includes complete systems manufactured in the United States, as well as extruders designed in the US and fabricated locally at Davis-Standard’s subsidiary Davis-Standard (Suzhou) Plastic Packaging Machinery Co., Ltd.

Davis-Standard supplies complete systems for a variety of tubing applications such as single lumen, multi-lumen, coextruded and Alternate Polymer® products. This technology supports applications for catheter tubing, endotracheal and tracheotomy tubing, radio opaque tubing, bump & taper tuber, pipette tubing and more. All tubing systems are produced and supported by Davis-Standard’s headquarters in Pawcatuck, Conn.

For extruders and extruder upgrades on existing lines, Davis-Standard has expanded its manufactured capabilities in Suzhou. All extruders sold in China are engineered and assembled to the same specifications and with the same components as U.S.-based machines while providing localized support and timely delivery. Extruders can be purchased individually or retrofitted to existing lines to improve outputs, stabilize pressure and melt, and optimize mixing of all thermoplastic resins. Davis-Standard’s engineers work directly with customers to determine the best strategy for achieving high line speeds and product tolerance based on application. This regional approach also permits Chinese customers to take advantage of RMB transactions for U.S. designed equipment without import fees, long transit times, and International shipment costs.

For more information about Davis-Standard’s medical tubing capabilities prior to the show, visit www.davis-standard.com/medical-tubing.

Photo Caption: HPE Medical Series 38mm and 25mm extruders for multi-layer tubing applications.

During K2019, Davis-Standard will promote its full menu of global aftermarket and technical services, aimed at providing convenience and improved performance for customers. This includes options for increasing productivity, reducing waste and strengthening product quality. Equipment upgrades, replacement parts, global field services, custom engineering, research and technical services, and a 24/7 customer service hotline (844-MYDAVIS) have enabled Davis-Standard to support customer needs in a cost-effective and timely manner. At K2019, Davis-Standard will show examples of readily stocked spare parts and support for heritage brands around the world. This includes technology upgrades to improve existing line performance with new feedscrew designs, controls and consulting services.

Feedscrew Services – Davis-Standard’s replacement or rebuilt feedscrews range from 3/4-inch (20mm) to 12 inches (305mm) in diameter. For feedscrew rebuilds, the screw is engineered back to its original performance characteristics and surface treatments. At K2019, Davis-Standard will be introducing a new spiral feedscrew design for groove feed applications.

Spare Parts – A large selection of mechanical and spare parts inventories enable Davis-Standard to ship in-stock parts within one business day. This includes feedscrews, barrels, thermocouples, heaters, motors and more. This is part of Davis-Standard’s 24/7 commitment to customer service where customers can access a service technician to handle emergency parts inquiries and service needs.

Extruder Rebuilds – Davis-Standard is able to transform aging equipment with improved efficiency and output with a fast turnaround. Extruder retrofit services include replacement of the extruder barrel, feedsection, screw and breaker plate, new controls, L/D conversions and more.

Safety Audits and Safety Upgrades – Davis standard offers line safety audits and upgrades to bring equipment in line with current standards. This service includes an on-site inspection of your existing extrusion lines and a detailed report. After review, a quotation is provided for parts and/or safety equipment requiring attention. Davis-Standard can provide installation and testing for all safety upgrades.

Process Control Upgrades – An upgraded EPIC III® system will be shown along with the next generation DS-eTPC II. Davis-Standard will continue in the short term to support the Extrol Control System on Gloucester Equipment with Spare Parts (subject to component level availability), testing of customers stock boards and a repair/replacement service. Davis-Standard through its Italyc’s and Epic platforms are also delighted to offer complete Extrol replacements for longer-term system security.

Davis-Standard provides complete control systems and upgrades for non-extrusion lines such as liquid coating applications and non-woven applications.

Rebuilds and upgrades of process controls, bag machines, winders, gearcases, dies and heads, and other extrusion equipment is a viable option for processors who want the latest technology at a fraction of the cost of replacement. For more information on Davis-Standard’s aftermarket services prior to K2019, visit https://davis-standard.com/service-support/parts-and-upgrades/.

Photo caption: Before and After aftermarket upgrade of a 1998 Davis-Standard 4-1/2” 20:1 Elastomer Extruder

Davis-Standard, LLC and Maillefer will showcase new technology at K2019 in Dusseldorf, Germany, Hall 16, booth #A43, October 16-23. A range of extrusion and converting technology will be shown, highlighting the ways Davis-Standard, Maillefer, Brampton Engineering and Thermoforming Systems LLC (TSL) deliver technology, value and market expertise to customers. Davis-Standard’s support of a circular economy in terms of sustainable processing practices, waste reduction and alternative polymer use will be at the forefront.

Davis-Standard, LLC and Maillefer will showcase new technology at K2019 in Dusseldorf, Germany, Hall 16, booth #A43, October 16-23. A range of extrusion and converting technology will be shown, highlighting the ways Davis-Standard, Maillefer, Brampton Engineering and Thermoforming Systems LLC (TSL) deliver technology, value and market expertise to customers. Davis-Standard’s support of a circular economy in terms of sustainable processing practices, waste reduction and alternative polymer use will be at the forefront.

“The K show is always a tremendous opportunity to connect with our global customer base,” said Jim Murphy, Davis-Standard President and CEO. “Our exhibit will highlight an excellent cross-section of technology at our booth. We will also share progress on our product lines and continual efforts to improve customer service responsiveness. K 2019 will also mark the second anniversary of our acquisition of Maillefer. This partnership has significantly broadened Davis-Standard’s reach and capabilities throughout Europe and the MEA regions.”

Following are highlights of the display:

- DS Activ-Check – This “smart” technology system enables processors to take advantage of real-time predictive maintenance by providing early notifications of potential machine failures. Machine operators are alerted to issues before they happen, reducing unplanned downtime while also collecting valuable data. Users receive notifications via e-mail or text, and continuous monitoring of production machine status is available on smart devices and remote PCs. Key parameters monitored include extruder reducer, lubrication system, motor characteristics, the drive power unit, barrel heating and cooling. The benefits of Activ-Check will be demonstrated on a profile line using Microsoft® Windows 10 on an EPIC III® control system.

- Bluebox

Maillefer’s Industry 4.0 data strategy is developed for high-speed acquisition and storage from all levels. Maillefer will show a lively implementation of a smart factory, where data from our different exhibits including the stand itself are correlated into informative dashboards. The real-time exhibit provides visitors with insight on how Industry 4.0 applies to their particular manufacturing environments.

- Elastomer Developments – Equipment for both medical and automotive applications will be shown. This includes silicone technology for producing medical grade silicone tubes, wound drains and catheters as well as elastomer capabilities for manufacturing hydraulic and automotive hoses and automotive seals. The Model 3000A crosshead is an example of this technology, reducing scrap and allowing faster start-up times. The crosshead offers preferred features such as a tapered mandrel and highly engineered flow paths to ensure consistent flow through all speed ranges, as well as a thrust bearing on pin adjustment to adjust wall thickness without interruption.

- Profile Capabilities – Pipe and tubing applications will be well-represented at K. This includes solutions and manufacturing configurations for automotive fuel and vapor tubes, micro-drip irrigation laterals, heating and plumbing pipe, blown fiber micro-duct, medical tubes, offshore flexible pipe, custom pipe and tubing, and wire and cable.

- New Extrusion Die for extrusion coating applications – The new Series 510A extrusion die will show the advantages of a short lip design and edge bead reduction (EBR) functionality. The die features an exchangeable lip optimized for specific resin types, a motorized internal and external deckling system for safe operation, an internal die channel for optimal melt flow and deckling adjustment, and an internal rod for edge bead reduction and leakage-free operation.

- Blown Film – The partnership of Gloucester Engineering and Brampton Engineering under the Davis-Standard banner offers customers with GEC Extrol control systems the ideal opportunity to upgrade their existing blown film control systems to ITALYCS® Additionally, the Vector® air ring will demonstrate how new air control technology can improve the uncorrected film gauge (also called starting gauge) by as much as 60 to 80 percent. The Vector® air ring provides stable air velocity resulting in consistent cooling to minimize variations in gauge across the width of the film.

- Aftermarket Advantages – Davis-Standard offers multiple services to support product line performance. This includes die reconditioning, new feedscrews to improve outputs and material homogeneity, and control system upgrades to enhance digitalization and product changeover. Davis-Standard also offers a full range of spare parts as well as feasibility studies to determine the potential of existing lines in terms of production increases, resin changes and product development.

For more information about Davis-Standard prior to the show, visit www.davis-standard.com

Photo Caption: Model 3000A crosshead die; Bearing monitor screen from D-S Activ Check; MXC 80-24D, MXC 45-24D and MXC 200-24D extruders from the family of Maillefer components; VLCH 305/400, TL 28 and ECH 8/24 extrusion heads from the family of Maillefer components (very large crosshead, longitudinal mono-layer head and multi-layer crosshead) Vector® air ring and operator

Europoligrafico (Fibrapak) of Perugia, Italy, recently improved efficiencies and line performance with a new control system from ER-WE-PA™ GmbH, a subsidiary of Davis-Standard, LLC. The new system was installed on an existing ER-WE-PA™ extrusion coating line used for aseptic liquid packaging applications. The control package features Siemens drives and a central S7 PLC with WinCC® visualization screens for managing all aspects of line control including speeds, extruder temperature, automatic die profile control, unwind and winder functions.

Europoligrafico (Fibrapak) of Perugia, Italy, recently improved efficiencies and line performance with a new control system from ER-WE-PA™ GmbH, a subsidiary of Davis-Standard, LLC. The new system was installed on an existing ER-WE-PA™ extrusion coating line used for aseptic liquid packaging applications. The control package features Siemens drives and a central S7 PLC with WinCC® visualization screens for managing all aspects of line control including speeds, extruder temperature, automatic die profile control, unwind and winder functions.

“One of the best and most cost-effective ways to improve operation on an existing line is with controls,” said Paul Knorsch, aftermarket business development leader at ER-WE-PA™ GmbH. “The supervisory control and data acquisition (SCADA) of this system simplifies operator functionality while allowing for greater monitoring and regulation of various parameters. We know Europoligrafico (Fibrapak) is already seeing a marked difference in line functionality.”

Knorsch noted that Fibrapak (www.fibrapak.com) is a new venture established between Europoligrafico and GS Pak of China. This allows Europoligrafico (Fibrapak) to become a full-system supplier with capabilities to provide printed, coated and laminated board in addition to filling machines and product handling. GS Pak also has an aseptic coating line from ER-WE-PA™ in their China plant.

For more information about Davis-Standard’s extrusion coating systems, visit www.davis-standard.com/converting_system/extrusion-coating/. For more information about Fibrapak, visit www.fibrapack.com.

Photo Caption: Europoligrafico’s extrusion coating line with updated controls