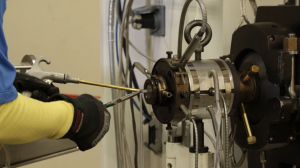

Purging flexible PVC from your Davis-Standard extruder and die head after each use is essential to maintain optimal equipment operation, avoid contamination and corrosion, and ensure product quality. In this seven-minute video, we provide a step-by-step demonstration of this important process. This includes the required tools, safety practices, equipment disassembly, and cleaning procedures for removing excess PVC from your flange, die head, mandrel, and feedscrew. Even if you’ve done this many times before, this video is an excellent refresher to achieve the best results.

Feedscrew maintenance is so important we have written 8 other blog posts on this subject. Check out the below:

Feedscrew and Design Truths for Improved Longevity, Part I

Feedscrew and Design Truths for Improved Longevity, Part II

Feedscrew and Design Truths for Improved Longevity, Part III

Essential Feedscrew and Barrel Maintenance Part I

Essential Feedscrew and Barrel Maintenance Part II

Essential Feedscrew and Barrel Maintenance III, Purging – Part 1 of 3

With these 8 blogs and the video tutorial in your maintenance toolkit, we hope it helps you achieve better quality products, keeps your machine running in tip-top shape, and your feedscrew as good as new for many years to come.

Have comments or questions about this video? Comments below!

Don’t forget to rate this blog post so we can provide more of the subjects you like!

If you need service assistance, please contact us.

Cheers,

D-S Connect Blog Team