December 13, 2021

Top Five Most-Read Blogs of 2021!Last December we counted down our top five blog posts of the year. This was such a big hit, we’ve brought it back! Some of these blogs were written in 2020 and 2019, but they continue to capture your attention; landing in our 2021 count-down. Your readership and feedback is appreciated – thank you! Without … Continue reading "Top Five Most-Read Blogs of 2021!"

Read More >November 29, 2021

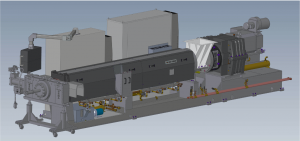

Groove Feed vs Smoothbore Smarter processing and a healthier bottom line depend on our ability to use available technology to our advantage! When it comes to HDPE product applications such as pipe extrusion, we have found that groove feed extruders offer significant advantages over smooth bore extruders. These benefits include increased output, reduced melt temperature, improved mixing quality, … Continue reading "Groove Feed vs Smoothbore"

Read More >November 9, 2021

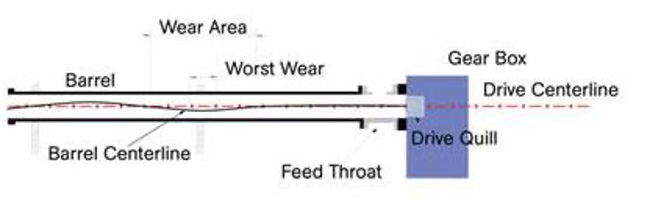

Aligning Your Extruder = Protecting Your InvestmentIs alignment important in order to optimize your extruder investment? You bet it is! And the longer the extruder barrel, the more significant alignment becomes. A poorly aligned extruder causes excessive wear and tear on both the screw and barrel. We’ve seen misalignment cause costly and unnecessary damage including premature wear, bent and broken screws, … Continue reading "Aligning Your Extruder = Protecting Your Investment"

Read More >October 25, 2021

Putting Safety First for Better Manufacturing!Creating a culture that values safety in the workplace is a key driver of quality, performance, and profitability. This blog will discuss the value of implementing a safety program.

Read More >October 12, 2021

Digital Transformation’s Value via Situational AwarenessIn the third part of the digital transformation series, we will take you through the three aspects of information processing - perception, understanding/interpretation, and prediction. By adopting situational awareness through technology, you will be able to enhance your extruder's performance and profitability.

Read More >September 27, 2021

Making Sense of Cloud-Based Digital ArchitectureIn this second blog of our digital transformation series, we explain the digital architecture of a cloud-based system using DS Activ-Check™ as an example and review its advantages.

Read More >September 13, 2021

Digital Transformation and What it Means for Our IndustryIn the first part of this exciting Digital Transformation 3-part series, we'll discuss what digital transformation is and how it has evolved and has affected our industry today and in the future. This is one series you certainly do not want to miss!

Read More >August 24, 2021

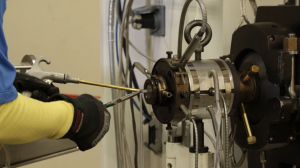

Purge and Feedscrew Cleaning Video TutorialPurging flexible PVC from your Davis-Standard extruder and die head after each use is essential to maintain optimal equipment operation. This video tutorial includes the required tools, safety practices, equipment disassembly, and cleaning procedures for removing excess PVC from your flange, die head, mandrel, and feedscrew.

Read More >August 9, 2021

Choosing the Right Machine for Your Reclaim Goals, Part IIIn the second part of the reclaim series, we take a step further by delving into the benefits of feed-assisted single screw extruders, including a crammer feeder, ram stuffer, and cutter compactor. Feed-assisted single screw options are a game-changer when bulk density is too low for gravity feeding or when dealing with problematic feeding material.

Read More >July 13, 2021

Choosing the Right Machine for Your Reclaim Goals, Part IReclaim extrusion is a worthwhile pursuit for processors looking to achieve sustainable practices while taking advantage of cost savings from re-using available materials. In the first part of this blog series, we’ll cover the basic characteristics of low bulk density materials as well as various single screw extruder designs.

Read More >