Recent News

Past News

John Zachow, Davis-Standard’s Vice President of Wire and Cable, was recently re-elected to another three-year term as a board member for the Wire and Cable Industry Supplier’s Association® (WCISA). Zachow will serve alongside other industry professionals in supporting WCISA companies, exhibits, outings and scholarships.

“WCISA is an essential organization in promoting and serving the wire and cable industry,” said Zachow. “I am honored to be able to serve another three years with such a talented and experienced group of peers. One of the great things that the association, including me, places great value in is the development of future industry members through education. We are very active in providing scholarships for college students of families of member companies and interns of member companies. Summer is our active time to solicit applicants for the many scholarships we provide for the fall. Over the years I have seen several awards granted both to interns and family members of Davis-Standard.”

WCISA is a nonprofit corporate membership organization of North American suppliers of machinery, materials and accessories used for making all types of wire and cable. The organization’s mission is to promote member products and services through representation, networking/social opportunities and services at wire and cable trade events and conferences.

For more information about Davis-Standard’s wire and cable capabilities, visit www.davis-standard.com/wireandcable/. For more information on the WCISA scholarships, please visit http://www.wcisaonline.org/pdfs/WCISA%20Scholarship%20Program.pdf.

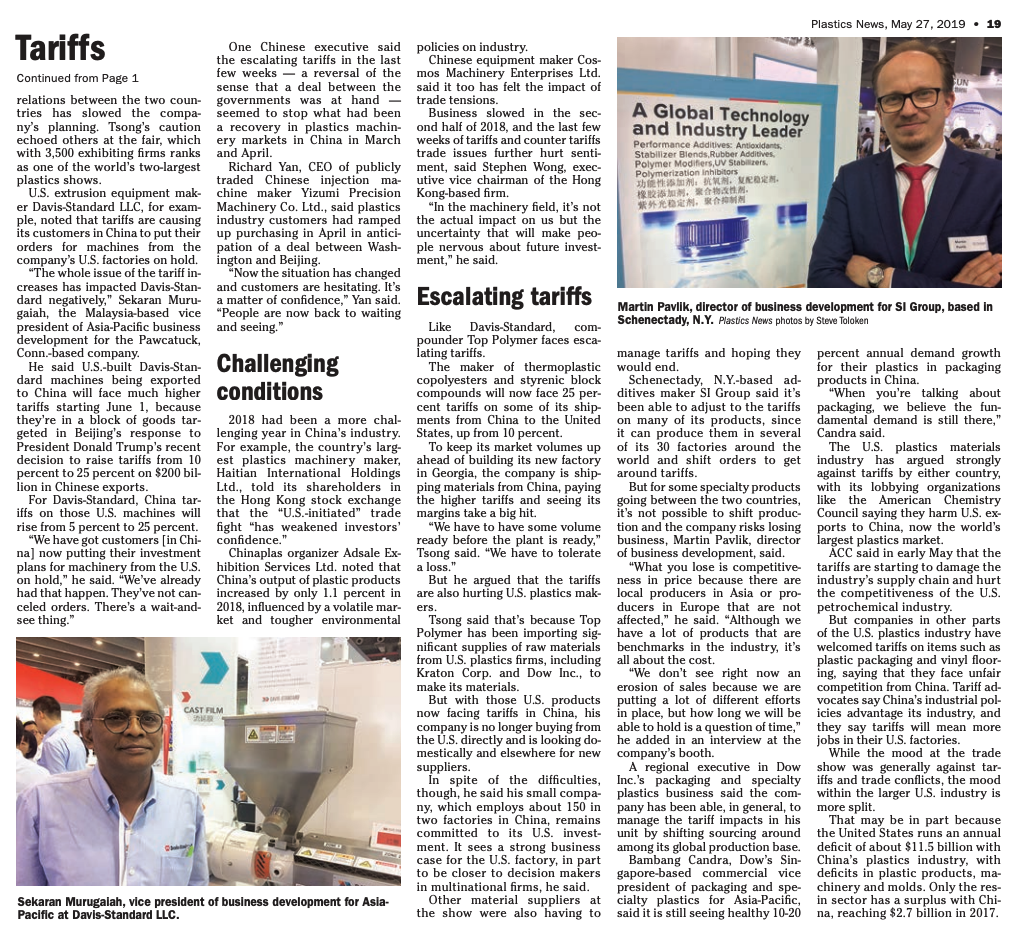

Southwire Company LLC, a leading manufacturer of high-voltage underground cable systems, aims to boost cable production and quality with the Maillefer Round Premium Package. Slated for installation later this year as an upgrade to an existing line, Southwire will be the first in North America to employ this capability. The company will be able to produce rounder cables as large as 6 inches (152mm) in diameter that weigh as much as 25 pounds per foot at production speeds faster than previous technology has allowed. Southwire will also be able to reduce material usage, which is significant due to the many plastic layers extruded over the conductor for safety and durability.

“We have a strong, long-standing association with Maillefer, a Davis-Standard company. Davis-Standard has augmented this relationship by providing local support for parts, service and purchasing, further improving the process,” said Chris McGill, Plant Manager at Southwire. “This upgrade to our vertical CV line not only supports better production, but it also benefits cable installers because rounder cables are easier to connect for longer lengths in the field.”

Southwire’s high-voltage power cable is engineered to run underground for power transmission and distribution from generation points to substations over long distances. Due to the trend away from bare conductors and overhead transmission lines, demand for this type of cable has increased dramatically. With Southwire’s international customer base, the upgrade will enable them to more effectively address current and future market growth. In addition to equipment, Maillefer will provide installation support, commissioning and training.

“We are excited to have a North American customer install and use this technology,” said John Zachow, Vice President of Davis-Standard Wire and Cable Systems. “This is going to differentiate their product while improving all aspects of production for this type of cable.”

For more information about Southwire, visit www.southwire.com. For more information about Davis-Standard’s wire and cable capabilities, visit www.davis-standard.com/wireandcable/. For more information about Maillefer, visit www.maillefer.net.

Photo Caption: Round Value Package Premium – technology designed for VCV lines to improve cable core roundness and simultaneously increase the curing capacity of the line

Southwire Company, LLC is a leader in technology and innovation and an emerging influence in the industrial electrical space, Southwire Company, LLC is one of North America’s largest wire and cable producers. Southwire and its subsidiaries manufacture building wire and cable, metal-clad cable, utility products, portable and electronic cord products, OEM wire products and engineered products. In addition, Southwire supplies assembled products, contractor equipment and hand tools. For more on Southwire’s products, its community involvement and its vision of sustainability, visit southwiresustainability.com.

Davis-Standard, LLC will promote the company’s elastomer extrusion technology, crosshead and facility expansion at Davis-Standard (Suzhou) Plastic Packaging Machinery Co., Ltd., during RubberTech China, Hall N1 booth #1A113, September 18-20 in Shanghai.

“RubberTech draws a wide base of potential customers from all parts of Asia,” said Joe Wnuk, Vice President of Davis-Standard Elastomer and Profile Systems. “It’s a valuable opportunity to interact with processors in multiple markets, and share the ways we are increasing output rates and lowering extrudate temperatures for nearly every elastomer compound formulation.”

Davis-Standard supports global elastomer markets for tires, automotive hoses, adhesives and sealants, recreational equipment, construction and medical applications. Elastomer-specific processing equipment is engineered for efficiency and performance, including a DSREV extruder and our latest crosshead design: The Model 3000 crosshead. The Model 3000 crosshead reduces scrap and enables faster start-up times. The hydraulic actuation of the flow diverter/core tube enables quick tooling changes and simplified cleaning. A tapered mandrel and highly engineered flow paths ensure consistent flow through all line speed ranges, and a thrust bearing on pin adjustment allows wall thickness modifications without stopping the line for a wide range of processes. All interior flow surfaces are coated with engineered formulations for better resistance, material flow and ease for cleaning operations. The 3000 has been updated to include port for both full or tip vacuum for improved process flexibility. In most cases, the head can be fitted to allow for use of existing customer tooling. The flow channel has been further enhanced to handle even the most demanding higher durometer materials. The updated design will allow for additional features to be announced soon!

The DSREV extruder has a patented pneumatic roll feed system for a uniform and consistent feed rate, electric heating and water-cooling for quicker response times, and feedscrews that maximize output and minimize scorch. Using a gear pump, processors are able to isolate high pressure and achieve pressure stabilization. Davis-Standard’s gear pump is equipped with a two-roll feeder (TRF) for cold feeding or to be used as a stand-alone device for fine mesh straining. Other advantages include improved filtration, reduced material retention time and a small footprint to easily integrate into existing lines.

To further support customers in the region, Davis-Standard recently expanded its manufacturing space and capabilities in Suzhou. The additional 35,000 square-foot (3,251 square-meter) facility near the existing shop houses control panel assembly and provides much-needed warehousing.

For more information about Davis-Standard’s elastomer systems, visit https://davis-standard.com/extrusion_system/elastomer/.

Photo caption: Davis-Standard model 3000 crosshead

Davis-Standard is pleased to announce that Craig Richardson has been appointed aftermarket sales manager for Thermoforming Systems, LLC (TSL). TSL, a Davis-Standard subsidiary, is the market leader in thermoforming equipment technology for high-volume packaging. Richardson will support TSL product line upgrades, tooling and parts, and provide responsive service to customers worldwide.

Davis-Standard is pleased to announce that Craig Richardson has been appointed aftermarket sales manager for Thermoforming Systems, LLC (TSL). TSL, a Davis-Standard subsidiary, is the market leader in thermoforming equipment technology for high-volume packaging. Richardson will support TSL product line upgrades, tooling and parts, and provide responsive service to customers worldwide.

“Craig brings over 30 years of global industry experience to his position,” said James Naughton, Executive Vice President of TSL. “He has extensive knowledge of thermoforming machinery, tooling and granulation, as well as the thermoforming process, tooling layout and production. We know he will deliver the timely service and expertise customers expect from Davis-Standard’s aftermarket team.”

Prior to Davis-Standard, Richardson was with Irwin Research & Development as the sales and marketing director. He will be based in Yakima, Washington.

If you would like to contact Craig, please reach out to marketing@davis-standard.com.

Davis-Standard is pleased to announce that Engineering Customer Centric Solutions (ENGICCS) Ltd. is the company’s new sales representative in West Africa. ENGICCS is a global player in the design, development and distribution of innovative solutions for packaging film, polymer electronics and converting systems. As Davis-Standard’s representative, they will be responsible for facilitating direct contact with plastics converters and stakeholders in West Africa to identify converting needs and market plastic packaging solutions throughout the region.

Davis-Standard is pleased to announce that Engineering Customer Centric Solutions (ENGICCS) Ltd. is the company’s new sales representative in West Africa. ENGICCS is a global player in the design, development and distribution of innovative solutions for packaging film, polymer electronics and converting systems. As Davis-Standard’s representative, they will be responsible for facilitating direct contact with plastics converters and stakeholders in West Africa to identify converting needs and market plastic packaging solutions throughout the region.

According to Dr. Anye Chifen, Managing Director of ENGICCS, “We look forward to increasing awareness of the Davis-Standard brand through strategic marketing avenues, while also providing more facetime with customers. A key part of our role in this region is to cultivate long-term partnerships and offer value-added solutions. This is an important step in gaining a greater understanding of customer needs and providing outstanding solutions to the industry.”

Davis-Standard recently participated in the Nigeria Plastprintpack + Agro Food Exhibition in late March. The exhibition proved to be a timely opportunity to discuss Davis-Standard’s solutions in flexible packaging and to learn more about Nigerian-based manufacturing companies. According to the National Agency for Food and Drug Administration and Control (NAFDAC) in Nigeria, the country’s plastic and packaging sector has experienced substantial growth in recent decades from around 50 companies in the 1960’s to more than 3,000 manufacturers today. Based on feedback from the show, Davis-Standard looks forward to supporting Nigeria’s rapidly growing converting and extrusion markets, specifically in the area of packaging films.

For more information about ENGICCS, visit www.engiccs.com. For more information about Davis-Standard, visit www.davis-standard.com.

Davis-Standard is pleased to announce the company’s manufacturing facility in Fulton, N.Y., recently celebrated 365 days without a lost time accident or OSHA recordable injury. This is a tremendous milestone credited to Davis-Standard’s high standards and safety practices for all employees. Dan Guthrie, Davis-Standard COO, said that attention to work area details, participation in safety training meetings, weekly area inspections, sharing toolbox talk points and a holistic team approach to improve safety for all site employees was key to reaching this milestone.

“Maintaining an injury-free workplace at all of our locations is our first initiative and top priority,” said Guthrie. “This milestone at our plant in New York is significant in achieving this objective. I commend our employees as this is not easy to do, even when you have standards of excellence in place. We look forward to celebrating this milestone at every Davis-Standard manufacturing facility worldwide.”

Photo Caption: Fulton, N.Y. operating team

Davis-Standard is pleased to announce customers worldwide can now take advantage of a new 24/7 First Responder phone number 844-MYDAVIS (844-693-2847). This central point of contact reflects Davis-Standard’s continued commitment to Comprehensive 360 Support of our global customers with technical, personalized and timely responses to all service inquiries. By calling this number, customers can reach our global support centers 24 hours a day to identify and quickly facilitate their requests. In addition, translation services are available in English, German, French, Spanish, Finnish and Mandarin.

Davis-Standard is pleased to announce customers worldwide can now take advantage of a new 24/7 First Responder phone number 844-MYDAVIS (844-693-2847). This central point of contact reflects Davis-Standard’s continued commitment to Comprehensive 360 Support of our global customers with technical, personalized and timely responses to all service inquiries. By calling this number, customers can reach our global support centers 24 hours a day to identify and quickly facilitate their requests. In addition, translation services are available in English, German, French, Spanish, Finnish and Mandarin.

“Implementing 844-MYDAVIS is an important step in supporting our global customers with the sense of urgency needed to keep their production schedules without delay,” said Jim Murphy, President and CEO of Davis-Standard. “Keeping up with our new brand standard, we are leading the way in providing solutions to support our customers’ uptime and competitiveness. The bottom line is, the customer wants to talk to the right person right away. We anticipate the addition of the 24/7 First Responder number (844-MYDAVIS) moves us closer to achieving that goal.”

For more information about Davis-Standard’s service capabilities, visit www.davis-standard.com/service-support/overview/.

Davis-Standard (Suzhou) Plastics Packaging Machinery Co., Ltd. is pleased to announce the expansion of the company’s manufacturing capabilities. Open for operation at the end of April 2019 is an additional 35,000 square-foot (3,251 square-meter) facility near the existing shop in Suzhou and will house control panel assembly and provided much-needed warehousing. The addition reflects Davis-Standard’s growing extrusion coating business and long-term strategy in the region.

Davis-Standard (Suzhou) Plastics Packaging Machinery Co., Ltd. is pleased to announce the expansion of the company’s manufacturing capabilities. Open for operation at the end of April 2019 is an additional 35,000 square-foot (3,251 square-meter) facility near the existing shop in Suzhou and will house control panel assembly and provided much-needed warehousing. The addition reflects Davis-Standard’s growing extrusion coating business and long-term strategy in the region.

“The additional space will allow us to build more extrusion coating lines at our main plant while supporting other machine services, including faster delivery,” said Jinsong Lin, general manager at Suzhou. “We also appreciate how close this building is to our existing facility. The increased manufacturing capacity is a positive reflection of our growth over the past few years. We have become one of the top equipment suppliers in the region and we don’t take that for granted.”

The medical tubing and packaging segments continue to be strong markets for Davis-Standard throughout Asia. Equipment sold to regional customers for medical tubing, extrusion coating and co-extrusion applications is built in Suzhou, as is assembly of electrical control panels, extruders and gearcases. There is also an impressive R&D facility at this location, equipped with technology for testing a range of rigid and flexible products, as well as FPVC tubing for IV and fluid delivery. Examples include microbore tubing, multi-lumen and catheter tubing, endotracheal and tracheotomy tubing, bubble tubing, taper tubing and others. Most recently, Davis-Standard added a new dsX flex-pack™ 300S to this lab for customer trials. This is a single station extrusion and lamination line built specifically for the Asian flexible packaging market.

For more information about Davis-Standard’s subsidiary in Suzhou, visit www.davis-standard.com.cn