Davis-Standard will exhibit its next-generation direct drive groove feed extruder along with its popular Thermatic® and Super Blue® extruders during NPE. These extruders exemplify processing versatility and performance, and will be shown with new feedscrew and control technology.

The 65mm direct drive groove feed extruder features a Davis-Standard Helibar® design with a grooved intake zone and helically grooved barrel, and new barrier-mixing feedscrew technology. This extruder and feedscrew combination offers increased processing flexibility due to higher regrind levels and improved pressure stability. It also enables processing of a wider range of polymers at lower internal pressure and with improved energy efficiency. The Helibar design is advantageous in terms of higher throughput, improved melt pressure build-up, lower melt temperatures, improved melt homogeneity, reduced barrel wear and a shorter residence time. Applications well-suited to this extruder include pipe, profile, sheet and blow molding processes.

Demand for the Thermatic and Super Blue models continues to be high as both models are advantageous in terms of reliablity, efficiency and proven performance. The 2 ½-inch (65mm) Thermatic being shown is an upgraded model with a modern platform and results-driven enhancements in terms of gearbox design, barrel cooling, vent diverter geometry and more. It will be part of a running TPE tubing line demonstrating the smart extrusion features of Industry 4.0 or IIoT (Industrial Internet of Things), essential for preventative and predictive maintenance. This includes monitoring of vibration, oil composition, motor parameters, heater status, screw wear algorithm and energy consumption. The Thermatic is available in L/D ratios of 24, 30 and 34:1 and can be equipped with any Davis-Standard DSB® feedscrew, as well as the TS DSBM, TS Metering, TS DS-Blend, and a variety of metering screws and specialized designs.

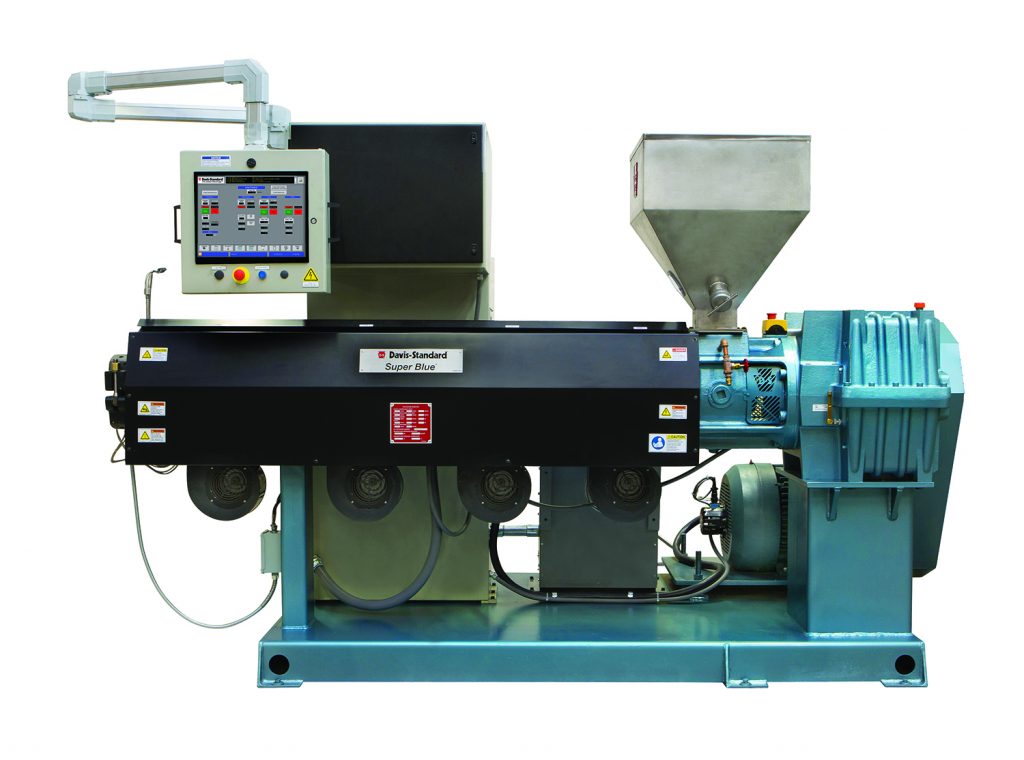

The Super Blue is advantageous due to its pricing, reliability and fast delivery. Customers appreciate the interchangeability of Davis-Standard feedscrews, rugged components such as the low-noise, double-reduction gearbox, minimal maintenance and consistent production rates. It is available in sizes ranging from 2 inches (50mm) to 4 ½ inches (114mm), each with the option of a 24:1 L/D ratio or 30:1 L/D ratio. At NPE, the Super Blue will be shown with the DS-eTPC II, the second generation of Davis-Standard’s widely used touch-screen control.

This controller is well-suited for pipe, profile and tubing, elastomer, wire and cable, sheet and reclaim applications. Notable enhancements include a larger 15-inch (380mm) viewing screen with multi-touch capabilities for zoom-in and out, extruder control for up to three extruders, and real-time and historical data trending.

For more information about Davis-Standard’s exruder capabilities prior to NPE, visit www.davis-standard.com/extruders.

Bue día,

En la compañía tenemos este tipo de extrusor y quisiera conseguir el manual tanto operativo como el de mantenimiento, y despiece de sus elementos. Y refacciones.

Me interesa saber para que capacidad es este modelo, hablando de velocidades, temperaturas,

Que relación hay entre velocidad y temperaturas…

El modelo que tenemos es el 211 7

El número de serie es E3074

S.O. 45820

Buenas tardes: hemos enviado tu solicitud al equipo correspondiente. Alguien se pondrá en contacto lo antes posible.

Gracias.