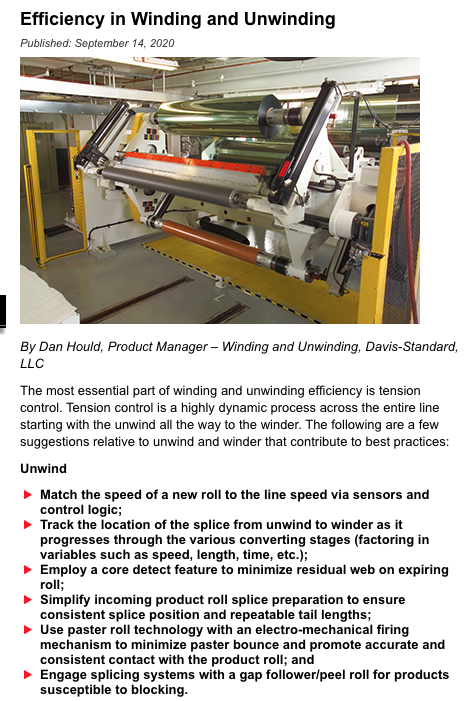

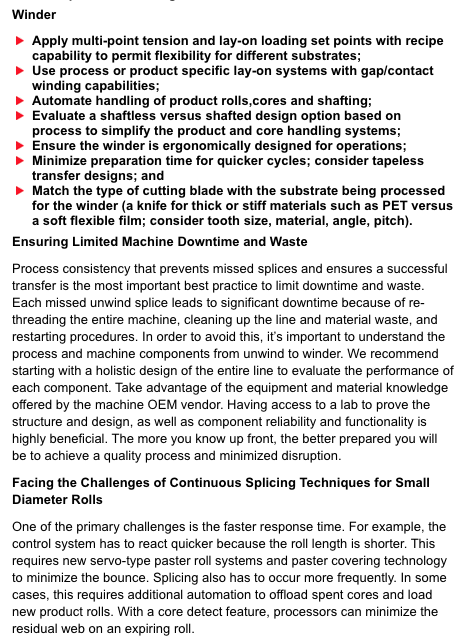

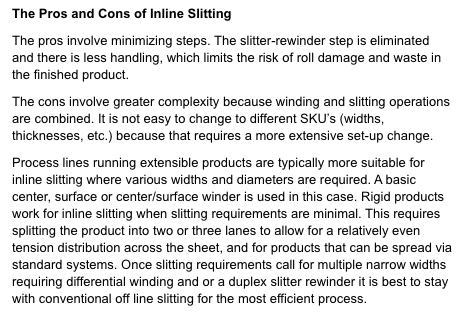

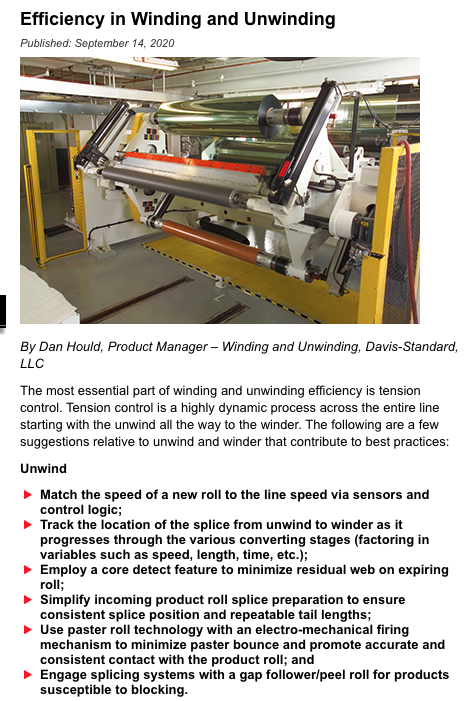

In a recent interview with PFFC, Dan Hould, Davis-Standard’s Product Manager, discusses the most essential part of winding and unwinding.

Check out the article on the PFFC website here.

In a recent interview with PFFC, Dan Hould, Davis-Standard’s Product Manager, discusses the most essential part of winding and unwinding.

Check out the article on the PFFC website here.

Davis-Standard is pleased to offer its popular “Basics of Plastics Extrusion” seminar, in virtual fashion, October 6 – 8, 2020. This three-day interactive seminar will cover the fundamentals of plastics extrusion, composition and properties of various polymers, and the mechanics of essential downstream processes. Session topics will include extruder components, temperature control, control systems, maintenance practices, screw and die design, among others. In addition, all participants will see a virtual borescoping and lab demonstrations, and receive a virtual tour of Davis-Standard’s manufacturing and technical facilities.

“This seminar has been extremely beneficial to customers who seek to improve the knowledge base of their engineering and operational teams to strengthen overall productivity,” explained John Christiano, Davis-Standard’s Vice President of Extrusion Technology. “Although the seminar will be in virtual format this year, it still contains the same amount of robust instruction and interaction with our engineering and technical teams. We look forward to an outstanding session.”

Daily instruction will begin at 10 a.m. and conclude at 3 p.m. for a total of 15 training hours. The fee is $695 per person with a 10 percent discount given for groups of three or more from the same company. Course books and materials are included. Class size is limited to promote student and teacher interaction.

For enrollment details or more information about this seminar click here.

Davis-Standard is pleased to announce that Brad Sprague has joined the company as Regional Sales Manager Aftermarket – Midwest Region. In this capacity, he will be responsible for all large aftermarket sales including feedscrews, barrels, feed sections, gearboxes, conversion packages, control upgrades and extruder and equipment rebuilds for customers throughout the midwestern United States. He will support all Davis-Standard product groups in this role. Sprague brings more than 27 years of experience to his position, most recently with Graham Engineering as a regional sales manager. He has previous experience with Davis-Standard as a regional manager for the pipe and profile and elastomer product groups, also serving the Midwest region. Sprague is an active SPE (Society of Plastics Engineers) member.

Davis-Standard is pleased to announce that Brad Sprague has joined the company as Regional Sales Manager Aftermarket – Midwest Region. In this capacity, he will be responsible for all large aftermarket sales including feedscrews, barrels, feed sections, gearboxes, conversion packages, control upgrades and extruder and equipment rebuilds for customers throughout the midwestern United States. He will support all Davis-Standard product groups in this role. Sprague brings more than 27 years of experience to his position, most recently with Graham Engineering as a regional sales manager. He has previous experience with Davis-Standard as a regional manager for the pipe and profile and elastomer product groups, also serving the Midwest region. Sprague is an active SPE (Society of Plastics Engineers) member.

Davis-Standard, LLC will market elastomer solutions encompassing product capabilities and support services at booth #1A113 during RubberTech China, September 16-18, in Shanghai. This will include the new model 3000A (automatic) crosshead as well as the company’s expanded manufacturing space at Davis-Standard (Suzhou) Plastic Packaging Machinery Co., Ltd. As the global extrusion community continues to address the COVID-19 pandemic, Davis-Standard remains steadfast in fulfilling customer needs while keeping the health and safety of employees a priority.

“After several months of adapting to the pandemic, we look forward to reconnecting with our customer base in Asia,” said Joe Wnuk, Vice President of Davis-Standard Elastomer and Profile Systems. “Now more than ever, it’s important to look at best practices in terms of equipment performance, employee safety, innovative products and supply chain efficiencies. We are eager to work collaboratively with customers to develop and support solutions specific to the Asian marketplace.”

Davis-Standard engineers elastomer equipment for the production of tires, automotive hoses, adhesives and sealants, recreational equipment, construction and medical applications. Elastomer-specific technology is designed for efficiency and performance, including the DSREV extruder and the company’s latest crosshead design, the Model 3000A crosshead for rubber hose applications. This crosshead helps reduce scrap and accelerate start-up times for smaller lots. The results in material savings, quick product changes, simplified maintenance and improved quality are significant. In addition, a hydraulic pump system is not needed and the compact design does not require hoses.

According to Wnuk, “One of the best features of this automatic design is the precision adjustment, which contributes to material savings due to tighter tolerances within specifications. This is especially valuable with frequent product and dimension changes, which are becoming more and more common.”

The DSREV extruder has a patented pneumatic roll feed system for a uniform and consistent feed rate, electric heating and water-cooling for quicker response times, and feedscrews that maximize output and minimize scorch. Using a gear pump, processors are able to isolate high pressure and achieve pressure stabilization. Davis-Standard’s gear pump is equipped with a two-roll feeder (TRF) for cold feeding or to be used as a stand-alone device for fine mesh straining. Other advantages include improved filtration, reduced material retention time and a smaller footprint to integrate into existing lines.

This is all supported by Davis-Standard (Suzhou) Plastics Packaging Machinery, Co., Ltd., which is central to the company’s customer focus in Asia. Developments in the areas of machine building and assembly, inventory and aftermarket services, field service engineering, and installation at customer sites have been essential to supporting customers. Last year, Davis-Standard added a 35,000 square-foot (3,251 square-meter) facility near the existing Suzhou shop to house control panel assembly and provide warehousing. In an ongoing effort to strengthen efficiencies and customer satisfaction, Davis-Standard’s Suzhou facility achieved ISO 9001:2015 certification. This validates processes across the board, internally and externally, and serves as a benchmark for the company’s commitment to operational quality and process improvement.

For more information about Davis-Standard elastomer systems prior to the show, visit https://davis-standard.com/extrusion_system/elastomer/.

Davis-Standard will market its extensive line of medical tubing solutions at booth 2R201 during MedTec China, September 14-16, in Shanghai. This includes complete systems manufactured in the United States, as well as extruders designed in the U.S. and fabricated locally at Davis-Standard’s subsidiary Davis-Standard (Suzhou) Plastic Packaging Machinery Co., Ltd.

Davis-Standard supplies complete systems for a variety of tubing applications such as single lumen, multi-lumen, coextruded and Alternate Polymer® products. This technology supports applications for catheter tubing, endotracheal and tracheostomy tubing, radio-opaque tubing, bump and taper tubing, pipette tubing and more. Complete tubing systems are available directly from Davis-Standard’s headquarters in Pawcatuck, Conn., or supplied locally from Davis-Standard’s Suzhou facility.

For extruders and extruder upgrades on existing lines, Davis-Standard has expanded its manufacturing capabilities in Suzhou. All extruders sold in China are engineered and assembled to the same specifications as U.S.-based machines while providing localized support and timely delivery. Extruders can be purchased individually or retrofitted to existing lines to improve outputs, stabilize pressure and melt, and optimize mixing of thermoplastic resins. Davis-Standard’s engineers work directly with customers to determine the best strategy for achieving high line speeds and product tolerance based on application. This regional approach also permits Chinese customers to take advantage of RMB transactions for Davis-Standard equipment without import fees, long transit times, and international shipment costs.

In an ongoing effort to strengthen efficiencies and customer satisfaction, Davis-Standard’s Suzhou facility achieved ISO 9001:2015 certification. This validates processes across the board, internally and externally, and serves as a benchmark for the company’s commitment to operational quality and process improvement.

For more information about Davis-Standard’s medical tubing capabilities prior to the show, visit www.davis-standard.com/medical-tubing.

Davis-Standard is pleased to introduce the next generation 510A die for extrusion coating applications. Engineered with an innovative short lip design and edge bead functionality, it builds on earlier generation Davis-Standard die offerings. Improvements include simplification of the die’s pre-land channel and internal deckling blade for easier cleaning and maintenance.

“Essential to this design is a motorized internal and external deckling system for safe and easy operation where internal die channel is optimized for melt flow and deckling adjustment for precision edge bead control,” said, Michael Schröder, Head of Sales EMEA and Product Management at Davis-Standard’s German subsidiary ER-WE-PA GmbH. “This die has shown minimal or no edge trim, and the elimination of high edges during testing. The 510A die is ideal for acid co-polymers, LDPE, LLPE, HDPE and PP resins among others for extrusion coating and lamination onto board, alumimum foil and for flexible packing applications.”

For more information about the 510A die and Davis-Standard’s extrusion coating capabilities, visit www.davis-standard.com/converting_system/extrusion-coating.