Recent News

Past News

The formidable growth of Warden Plastics’ Biomedia product range is evidenced by the company’s rising reputation in the global wastewater treatment sector. Warden, based in Luton, Bedfordshire, United Kingdom, recently added two Davis-Standard Euro Blue® extruders to its equipment line-up for producing random filter media products for wastewater processes. The extruders are part of a significant investment by Warden following a surge in demand by major water companies in the U.K. and throughout Europe. This brings the company’s Davis-Standard extruder total to five with future investments on the horizon.

The formidable growth of Warden Plastics’ Biomedia product range is evidenced by the company’s rising reputation in the global wastewater treatment sector. Warden, based in Luton, Bedfordshire, United Kingdom, recently added two Davis-Standard Euro Blue® extruders to its equipment line-up for producing random filter media products for wastewater processes. The extruders are part of a significant investment by Warden following a surge in demand by major water companies in the U.K. and throughout Europe. This brings the company’s Davis-Standard extruder total to five with future investments on the horizon.

According to Warden Plastics’ Managing Director Mark Barrett, “We are focused on high volumes, efficiency and quality for a large range of polypropylene products for the wastewater treatment market. Davis-Standard’s Euro Blue extruders perform exceptionally well in meeting our delivery and process targets, while also allowing us to run a cost-effective operation. We have a very good working relationship with Davis-Standard, and appreciate their responsiveness in addressing our requirements.”

Warden runs a customized Biomedia operation with a variety of patented designs engineered to reduce energy consumption, meet environmental goals and reduce costs. The company’s products are made using recycled and virgin polypropylene, which is essential due to superior bacterial adhesion properties when compared to competing products made with HDPE. Warden is diversified into several product areas, but launched its Biomedia brand in the 1980s. The company has an ongoing research partnership with Warwick University and Cranfield Water Sciences Institute (CWSI), an internationally recognized center of excellence in wastewater treatment technologies for research, education, training and consultancy. The Davis-Standard Euro Blue has been a solid performer for Warden due to its energy efficient design, high specifications and fast delivery.

According to Mark Woodgate, Managing Director of Davis-Standard Limited, “The Euro Blue has been a cost-effective option for customers like Warden to achieve quality, reliability and excellent processing rates. This machine also offers a lot of advantages in terms of feedscrew, gearbox and barrel technology. These extruders can also be delivered in two to three weeks. It’s rewarding working alongside Warden Biomedia to help them supply the most innovative biological filtering products to the marketplace.”

Warden has 60mm and 90mm Euro Blue models, but the machine is also available in 50mm, 75mm and 115mm sizes. The biological filter media manufactured on these extruders is feasible for both industry and municipal wastewater treatment applications requiring organic removal, nitrification and denitrification. Warden’s products are lightweight, compact, durable and corrosion resistant, and designed to eliminate the clogging and puddling associated with gravel, slag and clinker filter beds. In addition to wastewater treatment facilities, Warden’s Biomedia products are also used for agricultural and aquatic applications. Most of the company’s products are sold in the U.K. and Europe, but are also reaching customers in North and South America, Mexico and Turkey.

“This sector is about 30 to 40 percent of our total business, and growing,” added Barrett. “Biological processes need oxygen and residence time to properly breakdown during primary, secondary and tertiary treatments. Our polypropylene products are engineered for quality filtering throughout this process to provide the best return on investment. Warden’s Biomedia group will continue to focus on developing the best solutions for treating human and industrial effluents to protect human health and the environment.”

For more information about Warden Biomedia, visit www.wardenbiomedia.com. For more information about Davis-Standard’s Euro Blue extruder, visit www.davis-standard.com/extruders.

When Tempo Products, Inc. of Fresno, Calif., noticed output rates on their Davis-Standard extruder were two-thirds of capacity and material uniformity was inconsistent, the company realized it was time for a new feedscrew. The problem was, new feedscrews typically have a turnaround of eight or nine weeks; a timeframe Tempo Products could not afford as a company with same-day product shipping. Davis-Standard’s aftermarket team rallied to the call, delivering and installing a new feedscrew within five weeks, restoring production rates and keeping Tempo Products’ tight production timelines on track.

When Tempo Products, Inc. of Fresno, Calif., noticed output rates on their Davis-Standard extruder were two-thirds of capacity and material uniformity was inconsistent, the company realized it was time for a new feedscrew. The problem was, new feedscrews typically have a turnaround of eight or nine weeks; a timeframe Tempo Products could not afford as a company with same-day product shipping. Davis-Standard’s aftermarket team rallied to the call, delivering and installing a new feedscrew within five weeks, restoring production rates and keeping Tempo Products’ tight production timelines on track.

“Like most processors, we are so engaged in keeping up with business and taking care of customers that we overlook periodic feedscrew maintenance,” said Rael Sacks, founder and co-owner of Tempo Products. “We pulled the feedscrew once since purchasing the extruder in 2012, and didn’t have any issues until recently, so we didn’t think about it. Once the new screw was installed, everything was back to normal in five minutes. We pride ourselves on customer service, so being able to avoid production delays is essential.”

Tempo Products uses this extruder to process linear low-density polyethylene and flexible PVC tubing for drip irrigation products sold to major retailers throughout the United States. The company is family owned and Sacks works alongside his sons and business partners, David and Jonathan, to offer a full line of water conservation and drainage products for residential and commercial applications. They sell through distribution channels with a same-day shipping policy for orders that come in before 4 p.m., thus the importance of consistent, high-rate production. The newly installed feedscrew is a replica of the previous screw except with a harder finish.

“We got a lot of mileage out of the first feedscrew, and are grateful Davis-Standard was able to accommodate this rushed delivery. We definitely plan to do more frequent feedscrew and barrel checks to avoid this issue in the future,” added Sacks.

Davis-Standard offers a complete line of aftermarket services to support feedscrew and barrel efficiency. Factors to consider include feedscrew, barrel and drive alignment, barrel heating uniformity, materials being processed, improper barrel support and corrosion. Periodic inspections at 90- to 180-day intervals are recommended. The two primary methods for evaluating feedscrew output loss include the accurate method and approximation method. The accurate method compares current screw output with production benchmark output, which is established upon feedscrew installation. The approximation method involves measuring the feedscrew, calculating the resultant added screw-to-barrel clearance and estimating the output loss from the added clearance. This technique requires approximately 24 hours of downtime while the feedscrew is being removed, cleaned and measured.

Following are the guidelines when using the approximation method. A measurement of .010 to .015 inches (.25 to .38mm) plus the original feedscrew and barrel clearance is indicative of wear, but the condition is not critical. A measurement of .020 to .030 inches (.5 to .76mm) plus the original screw and barrel clearance indicates feedscrew or barrel replacement should be considered. When the measurement reaches .040 to .050 inches (1 to 1.3mm), this is severe wear and it is essential to replace the feedscrew or barrel, or both.

For more information about Tempo Products, visit www.tempoinc.com. For more information about Davis-Standard’s aftermarket capabilities, visit www.davis-standard.com/aftermarket.

Davis-Standard will promote market-leading technology for the manufacture of complete wire and cable systems for aerospace, rubber cables, building wire and other high-demand applications at Wire Russia, June 5-8, in Hall FO, Booth #B22. Experts will be available to discuss various system options and the advantages of Davis-Standard extruders, payoffs, tension brakes, takeups, capstans, caterpillars and auxiliary equipment based on application. Information on laboratory equipment, customized feedscrews and control systems will also be on hand.

Davis-Standard’s high-performance wire handling equipment includes payoffs, take-ups and caterpillar capstans. Single wheel (belt wrap) capstans are sized from 24 to 84 inches (600 to 2,150 mm) in diameter; dual wheel multi-pass configurations from 12 to 48 inches (300 to 1,200 mm) in diameter; and in lengths up to 40 feet (12 meters) for dry and wet arrangements. Single reel, dual reel, flyer, and portal pay-offs and take-ups are equipped with options for portal, cantilevered arm and floor traversing. For added support, Davis-Standard supplies auxiliary equipment including cooling troughs, semi-automatic and fully automatic spoolers, wire pre-heaters and curing systems.

For more information about Davis-Standard’s extensive wire and cable capabilities visit www.davis-standard.com/wire-and-cable.

It’s no secret that Davis-Standard has the industry’s most extensive laboratory capabilities for both extrusion and converting applications. With R&D labs in Pawcatuck, Conn., Fulton, N.Y., and at the company’s subsidiary in Suzhou, China, customers have multiple options for making parts for proof-of-concept, experimenting with new resins, conducting materials development, and testing equipment prior to making large capital investments. According to John Christiano, Davis-Standard’s Vice President of Technology, the range of lab capabilities has been instrumental in supporting customers pre and post purchase, while also allowing for continuous internal technology development for Davis-Standard.

“Davis-Standard has always prioritized technology development,” said Christiano. “I think it’s one of our greatest attributes, making us unique as a company. Over the past year, we’ve had more than 150 customer lab trials among our three lab locations. These trials have included screw design development for smooth bore, groove feed and high-speed extruders, as well as product development trials for medical tubing, cast film, sheet and liquid coating applications. We use a wide range of resins, including those for multi-layer coextrusion applications. It’s always rewarding to see how this technology improves customer processes and profitability.”

Christiano noted that each lab gives customers multiple options in terms of equipment, control systems and feedscrew technology. The labs are also staffed by extrusion engineers with hundreds of years of combined experience and industry knowledge. Following is a summary of lab capabilities at each location.

Pawcatuck Lab

At Davis-Standard’s Technical Center in Pawcatuck, the company offers labs for single screw extrusion, coextrusion sheet applications and medical tubing. The single screw extruder lab has both smooth bore and groove feed technology as well as a high-speed extruder, vented and non-vented options, and extruder L/D configurations ranging from 24:1 to 40:1 depending on application. The coextrusion sheet line is set up for running sheet in various thicknesses with advantages such as hands-free roll gap adjustment, gravimetric blending, thin-gauge capabilities, melt pumps and screen changers, and multi-component blenders and cantilevered winding. The focus of the medical tubing development lab is product and equipment development for tubing used in medical devices ranging from single-lumen to multi-lumen applications. The facility is in a climate-controlled environment for running multiple resins including high temperature PEEK and corrosive materials like FEP. This lab also incorporates Davis-Standard’s patented Alternate Polymer® technology.

Fulton Lab

The Fulton lab is committed to converting processes, offering capabilities for unwind and winding, extrusion coating, lamination and cast film applications, as well as liquid coating and pelletizing. The winding and unwinding lab enables customers to evaluate different methods of unwinding, rewinding and automatic transfer as well as technology for cost-effective roll changes and dual direction winding. For coating, lamination and cast film processes, the line is set up for cast films up to 54 inches (1,372mm) wide and for extrusion coating in widths up to 50 inches (1,270mm). This includes resin blending, drying capabilities, coextrusion feedblocks and a selection of dies, winding and unwinding options. The liquid coating production and pilot line features advantages such as a multifunctional cooling section with laminating nip, auxiliary single position unwind, turret winder roll changer, SurfaStart winder, and configurations for reverse gravure, direct gravure, slot die, contact die, smooth, hot melt and more. The pelletizing lab is comprised of an extrusion system for underwater/water or air ring pelletizing.

Suzhou Lab

To support regional customer trials and application development, the Suzhou laboratory offers a high-speed FPVC extrusion system and multipurpose microbore tubing line. The FPVC line is capable of line speeds from 5 to 100mpm for processing 2mm to 8mm OD tubing with accuracy of +/- 50u. Line components include a 63mm extruder, 8m water cooling, precision internal air supply, OD gauge and combination puller-cutter. The multipurpose micro bore tubing line is designed for single or dual layer tubing, and single lumen tubing with or without a stripe. It is equipped with two extruders, OD/ID wall thickness measuring and controlling system, close loop control via vacuum sizing tank and puller, and a high level central control system. Davis-Standard is planning to add a dsX flex-pack™ 300S, a single station extrusion and lamination line, to this lab for customer demonstrations by the fourth quarter of 2018. This line is specifically engineered for the Asian flexible packaging market in terms of machine footprint, speeds and output, and the ability to make shorter runs.

To schedule a laboratory trial, customers can contact the following people at each location:

Pawcatuck: Bill Lee, 860-599-6722, blee@davis-standard.com

Fulton: Jeff Lawler, 315-593-0253, jlawler@davis-standard.com

Suzhou: Jinsong Lin, +86 512-62695139, jlin@davis-standard.com

For more information about these laboratories and specific components in each, visit www.davis-standard.com/lab-trial-opportunities.

It is rare to find the life’s work of one individual embedded within a single organization. For Dave Smith of Davis-Standard Limited in Brierley Hill, West Midlands, U.K., this has been the case for 50 years. Smith, a works engineer, celebrated his golden anniversary with the company in April.

“It is an absolute privilege to honor such dedicated service. Dave is a diligent, hardworking man who is well respected by his peers and customers alike,” said Mark Woodgate, Managing Director of Davis-Standard Limited. “He is a pleasure to work with, and his work ethic is an example and inspiration to all of us.”

Smith joined Davis-Standard Limited in West Midlands in 1967, when it was Brookes (Oldbury) Limited. He began as an apprentice, working on machinery for the automotive industry as well as bimetallic barrel and screw production for the plastics industry. Upon completing his apprenticeship, Smith became a maintenance fitter and was quickly promoted to maintenance foreman. In 2001, the company was purchased by Davis-Standard, LLC, and Smith’s duties continued to evolve and expand. Today as a works engineer, Smith prepares equipment for testing, conducts machinery rebuilds such as gearbox and die rebuilds, performs waterbath and downstream equipment assembly, and provides field services including borescoping.

“I’ve always enjoyed working with machinery because there are always new challenges and problems to solve. There has never been a day when I didn’t enjoy coming to work,” said Smith.

Smith’s longevity and extensive machinery knowledge have been an asset to Davis-Standard Limited, a division of Davis-Standard, LLC. While the company continues to support barrel and feedscrew customers, which was Brookes’ (Oldbury) original market sector prior to the acquisition, it is now more closely aligned to the core business of Davis-Standard. This includes the supply of extruders and downstream equipment for the EMEA (Europe, the Middle East and Africa) region as well as aftermarket support.

“From turnkey extrusion systems through rebuilds and upgrades, to the smallest of spare parts, our team has the capability to support customers,” added Woodgate.

In addition, Davis-Standard Limited recently added blown film die rebuild and cleaning services last year. These services apply to all blown film dies from Davis-Standard product lines and Heritage brands, including Gloucester Engineering Company. Services are available both on-site and off-site to ensure customer needs are addressed in a timely manner.

“Dave’s knowledge of our business and his ability to provide expertise for the entire scope of his work has been instrumental to our success,” added Woodgate. “We are grateful to him and for all he does on a daily basis to support customers.”

For more information about Davis-Standard Limited, visit www.davis-standard.com/worldwide-facilities.

Davis-Standard, LLC, Hall 9.2, Stand J41, looks forward to a productive Chinaplas in Guangzhou, May 16-19. As an example of its extrusion technology, Davis-Standard will exhibit an HPE-H extruder for medical tubing applications. The energy-efficient HPE-H is compact in design, available for a fast delivery, easy to maintain and one of the company’s most widely used models. It is available in 20mm (3/4-inch), 25mm (1-inch), 30mm (1 ¼-inch), 40mm (1 ½-inch) and 45mm (1 ¾-inch) sizes for processing versatility.

Davis-Standard, LLC, Hall 9.2, Stand J41, looks forward to a productive Chinaplas in Guangzhou, May 16-19. As an example of its extrusion technology, Davis-Standard will exhibit an HPE-H extruder for medical tubing applications. The energy-efficient HPE-H is compact in design, available for a fast delivery, easy to maintain and one of the company’s most widely used models. It is available in 20mm (3/4-inch), 25mm (1-inch), 30mm (1 ¼-inch), 40mm (1 ½-inch) and 45mm (1 ¾-inch) sizes for processing versatility.

Davis-Standard continues to see strong demand throughout Asia for feedscrews, control systems, medical tubing technology, and its dsX™ product line for cast film, blown film and packaging applications. Davis-Standard’s regional presence has continued to grow since opening Davis-Standard (Suzhou) Plastics Packaging Machinery Co., Ltd. in 2012. This facility is Davis-Standard’s manufacturing base in China and houses an R&D laboratory for process development and trials.

“We’ve experienced growth across all platforms in China, but the medical tubing sector has been especially strong for us,” said Sekaran Murugaiah, Davis-Standard Vice President of Business Development, Asia. “Customers appreciate our regional presence and the availability of the medical tubing laboratory in Suzhou to test new resins and processes. These R&D capabilities have been key in ensuring customers in the region are equipped to address market demands.”

The Suzhou lab features direct-drive 19mm and 24mm single screw extruders, each with a polymer melt pump, a sophisticated three-layer spiral flow tubing die, PLC line control with data acquisition, precision vacuum sizing tank for both rigid and flexible products, closed loop ID/OD control via an ultrasonic gauging system, a servo controlled combination puller/cutting system, and a transport conveyer with single-zone air eject. It also includes a single layer tubing line designed specifically for the production of FPVC tubing for IV & fluid delivery applications. Products ranging in size from 2mm OD to 8mm OD can be produced with an accuracy of +/- 50u at line speeds up to 100mpm. Davis-Standard’s facility in Pawcatuck, Connecticut, also has a fully equipped medical tubing laboratory.

Both labs support applications for Alternate Polymer®, microbore tubing, multi-lumen and catheter tubing, edotracheal and tracheotomy tubing, radio opaque tubing, bubble tube, taper tube, pipette tubing and multi-layer tubing, among others. Complete medical tubing systems support extruder outputs up to 315kg/hr (700 pounds per hour) and line speeds up to 240 mpm (800 feet per minute) for a range of materials including PLA, PLLA, PEEK, FPVC, polyurethane, nylon, PEBAX and FEP. Extruder options are available depending on process and application and engineered for a fast delivery and competitive pricing.

For more information about Davis-Standard prior to Chinaplas, visit www.davis-standard.com.

Davis-Standard will demonstrate a running wire and cable take-up along with capstan technology, and a new cut and feed machine at booth # 1023 during Interwire, May 9-11 in Atlanta, Georgia. The 2200mm take-up being shown is part of Davis-Standard’s line of traversing and collapsible take-ups and pay-offs. These designs offer a smaller overall footprint and enhanced operator ergonomics. Davis-Standard will also feature its new cut and feed machine to support low voltage wire and cable processes for insulating applications.

Davis-Standard will demonstrate a running wire and cable take-up along with capstan technology, and a new cut and feed machine at booth # 1023 during Interwire, May 9-11 in Atlanta, Georgia. The 2200mm take-up being shown is part of Davis-Standard’s line of traversing and collapsible take-ups and pay-offs. These designs offer a smaller overall footprint and enhanced operator ergonomics. Davis-Standard will also feature its new cut and feed machine to support low voltage wire and cable processes for insulating applications.

The take-ups and pay-offs integrate simplified engineering and cost efficiency. Machine sizes range from 1,250mm to 5,000mm (48 to 195 inches) with the greatest concentration within the 1,800mm to 2,500mm (70 to 98 inches) size range. Each is available with a North American standard controls platform, which includes a Yaskawa A-1000 AC drive and Allen-Bradley/Rockwell components encompassing servo drive, PLC (programmable logic controller) and HMI (human machine interface). For international projects, machines are equipped with a Siemens AC drive, PLC and HMI with a Mitsubishi servo drive. Technology is available as “stand-alone” (running in torque control) with a dancer or with an accumulator.

In addition, Davis-Standard will be demonstrating its new cut and feed machine. Designed for efficiency, this unit facilitates timely transfers from one take-up to the other, while minimizing operator involvement. This expedites the take-up reel change process during insulation and enables wire and cable manufacturers to boost outputs.

Also being shown is a caterpillar capstan. The capstan features multiple independently loaded pressure tracks. Davis-Standard supplies multi-pass, linear and belt wrap capstans for the full range of wire and cable applications.

The ability to address market demand in terms of performance and cost efficiency is just one of Davis-Standard’s extensive capabilities in wire and cable. Another is Davis-Standard’s unmatched experience in supplying extruders and associated wire and cable equipment for more than 70 years. Applications include aerial cable, building wire, coaxial and composite cable, video pair cable, tray cable, CATV, THHM and THWN wire among others. For more information, visit www.davis-standard.com/wire-and-cable.

The installation of a new 6-inch (150mm) Davis-Standard extruder and strategic line upgrades have enabled Mid South Extrusion of Monroe, Louisiana, to improve throughputs while delivering a broader slate of HDPE procession options. The modernizations were made to an existing Davis-Standard blown film line that has been in continuous operation for nearly 30 years. Mid South, a leading North American supplier of converting and process films for industrial packaging markets, has been a Davis-Standard customer since opening its doors in 1986.

The installation of a new 6-inch (150mm) Davis-Standard extruder and strategic line upgrades have enabled Mid South Extrusion of Monroe, Louisiana, to improve throughputs while delivering a broader slate of HDPE procession options. The modernizations were made to an existing Davis-Standard blown film line that has been in continuous operation for nearly 30 years. Mid South, a leading North American supplier of converting and process films for industrial packaging markets, has been a Davis-Standard customer since opening its doors in 1986.

The larger MAC extruder along with a new feedscrew, screen changer and control system have enabled Mid South to boost processing rates and options for different HDPE, LDPE and LLDPE films on an existing line while minimizing downtime. This project took approximately six months from order to installation, accommodating Mid South’s customer scheduling. Mid South chose a smooth bore extruder to allow flexibility for a wider range of materials.

“We have a strong history of infrastructure reinvestment and are always looking to make operational improvements. Projects like this have a very short return on investment and open the door to greater opportunities,” said Mike Henagan, Executive Vice President of Operations at Mid South. “The extruder and upgrade decisions were based on improved performance, quality and material selection. Davis-Standard is the only extruder manufacturer we trust for smooth bore technology for HDPE. Most manufacturers only offer groove feed. We also appreciate the timely delivery and installation, which allowed us to avoid production conflicts.”

Davis-Standard’s ability to seamlessly upgrade line components, even on non Davis-Standard brands, is one of its most valued services to customers. Specific to blown film, these capabilities were further augmented in 2016 with the acquisition of Gloucester Engineering Company (GEC). The option to add new technology, improve processing rates and support new applications without purchasing a new line enables company’s like Mid South to get the most out of every equipment investment.

“The recent upgrades will support reliability and quality for many years to come,” said Henagan. “With ongoing investment and our dedicated team of employees, Mid South customers can continue to expect the very best films on the market.”

For more information about Mid South Extrusion, visit www.midsouthextrusion.com. For more information about Davis-Standard’s blown film capabilities, visit www.davis-standard.com.

Davis-Standard, LLC will promote the company’s recent expansion and equipment innovation in Hall 8.1, Booth D19, during CHINAPLAS 2018 in Shanghai, April 24-27. Among Davis-Standard’s latest developments are the recent acquisition of Maillefer, the company’s strengths in Suzhou, expanded dsX flex-pack™ technology for extrusion coating, and new stretch film capabilities. Davis-Standard will also exhibit a MEDD extruder (Medical Extruder Direct Drive).

Davis-Standard, LLC will promote the company’s recent expansion and equipment innovation in Hall 8.1, Booth D19, during CHINAPLAS 2018 in Shanghai, April 24-27. Among Davis-Standard’s latest developments are the recent acquisition of Maillefer, the company’s strengths in Suzhou, expanded dsX flex-pack™ technology for extrusion coating, and new stretch film capabilities. Davis-Standard will also exhibit a MEDD extruder (Medical Extruder Direct Drive).

Davis-Standard’s acquisition of Maillefer in 2017 expanded the company’s wire and cable, pipe and tube equipment offering, and added facilities in Finland and Switzerland to better serve customers, including those in China. Wire and cable capabilities include automotive, building wire, coaxial cable, LAN, fiber optic MV, HV and EHV among others. For pipe and tube applications, this includes automotive, heating and plumbing, irrigation, medical, micro-duct, off-shore and custom lines. The Maillefer addition complements Davis-Standard’s presence in China with Davis-Standard (Suzhou) Plastics Packaging Machinery, Co., Ltd. The Suzhou facility is Davis-Standard’s manufacturing base in China, offering equipment for FPVC medical tubing and co-extrusion applications as well as assembly of electrical control panels, extruders and gearcases.

In addition to manufacturing, Suzhou is home to an R&D laboratory to support Asia’s growing medical market. The lab is equipped with technology such as the MEDD extruder (being shown) to test a range of rigid and flexible products as well as FPVC tubing for IV & fluid delivery. Applications include microbore tubing, multi-lumen and catheter tubing, endotracheal and tracheotomy tubing, radio-opaque tubing, bubble tubing, taper tubing, pipette tubing and multi-layer tubing, among others. The MEDD is specifically engineered for these tight tolerance applications due to its compact design, energy efficiency and materials versatility. Advantages of this extruder model include linear movement, a replacement feedsection liner, interchangeable barrel assemblies and Windows®-based control system.

“Our location in Suzhou has been instrumental to our growth in China,” said Sekaran Murugaiah, Davis-Standard Vice President of Business Development, Asia. “For example, one customer has made Davis-Standard

their preferred extruder provider due to our regional presence and consistent equipment performance. We also continually build upon equipment strengths such as our dsX™ product line as well as manufacturing and service capabilities addressing the needs of the Asian market. Chinaplas is an ideal platform for this exchange and we anticipate another productive show.”

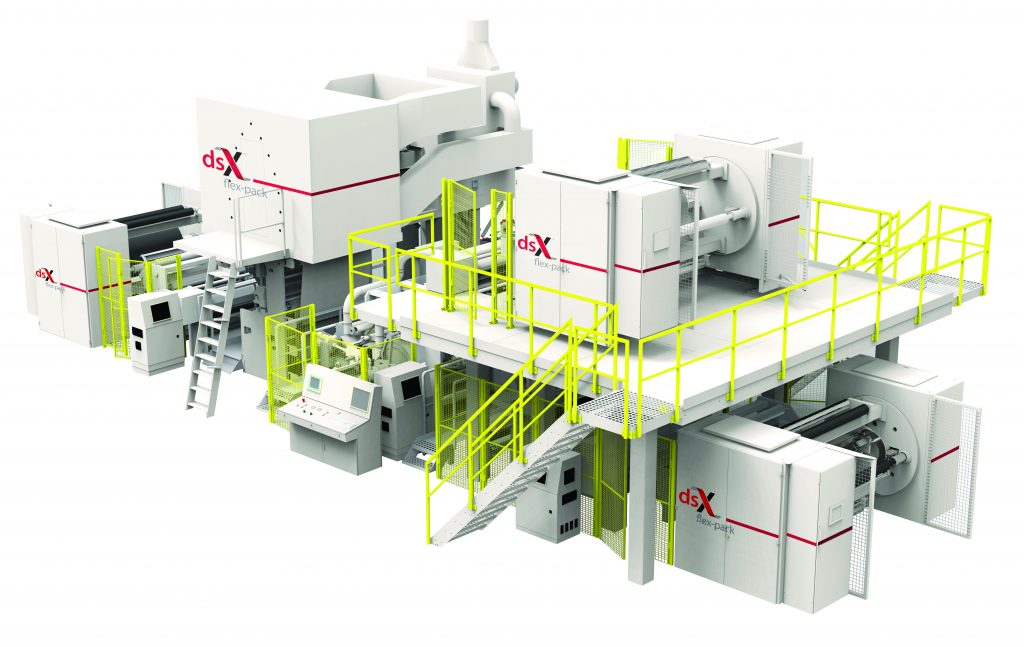

The latest dsX flex-pack model is the 300S, which is a single station extrusion and lamination line with benefits specifically engineered for the Asian flexible packaging market. Design of the dsX flex-pack™ 300S is a collaboration between Davis-Standard’s teams in the U.S., Germany and China to ensure that pricing, machine footprint, speeds and output, and the ability to make shorter runs would accommodate demands of converters. In addition, Davis-Standard will offer a tandem configuration of this machine called the dsX flex-pack™ 300T for the Asian flexible packaging market. Davis-Standard plans to have its first dsX flex-pack 300S demonstrated during a customer open house in Suzhou in the fourth quarter of 2018.

Davis-Standard also anticipates that its new stretch film line with the DS S3 winder will be beneficial to Asian converters. Quality control, versatility and efficiency are hallmarks of this technology. The line offers a compact machine arrangement, ease of servicing, excellent profile control, consistent roll quality and an intuitive control package. It is engineered for producing thin films from 31-to 51-gauge (7.8µ to 13µ) at high speeds. Davis-Standard’s side-by-side DS S3 overlapping winder is essential to this capability. The DS S3 winder enables maximum slit widths for hand-wrap, machine-wrap and jumbo rolls, supporting multiple market segments on one winder. Films discharge out the front of the line to a common side to simplify roll packing and future automation. Cores are also same-side loaded from the back to prevent disruption of packing activities. There is an auxiliary lay-on roll to eliminate top-wind waste during transfer, optimizing roll quality and eliminating outer wrap transfer waste. All features are advantageous for high-grade film operations.

For more information about Davis-Standard prior to Chinaplas, visit www.davis-standard.com.

North American building wire and cable manufacturer Republic Wire has grown its business and product line with the reliable performance of Davis-Standard wire and cable extrusion technology. In just over three years, Republic Wire has installed five Davis-Standard lines with another large THHN line on order, due for delivery in mid 2017. As with the other lines, Davis-Standard will build the line to Republic Wire’s specifications. Republic Wire has expanded its product line in recent years, which now includes tinned copper wire, bare copper, insulated building wire such as THHN, THW, NMB and XHHW, USE and poly-weatherproof wire. The Ohio-based manufacturer serves electrical wholesale distributors, utility distributors, industrial distributors, investor-owned utilities and municipalities throughout the United States and Canada.

North American building wire and cable manufacturer Republic Wire has grown its business and product line with the reliable performance of Davis-Standard wire and cable extrusion technology. In just over three years, Republic Wire has installed five Davis-Standard lines with another large THHN line on order, due for delivery in mid 2017. As with the other lines, Davis-Standard will build the line to Republic Wire’s specifications. Republic Wire has expanded its product line in recent years, which now includes tinned copper wire, bare copper, insulated building wire such as THHN, THW, NMB and XHHW, USE and poly-weatherproof wire. The Ohio-based manufacturer serves electrical wholesale distributors, utility distributors, industrial distributors, investor-owned utilities and municipalities throughout the United States and Canada.

“Davis-Standard is a quality supplier, offering value at purchase time and value in uptime. They are always flexible with what we need, and do an excellent job of meeting space and production requirements,” said Dave Hadley, Plant Manager for Republic Wire. “We especially appreciate the commissioning and installation crews, and the support they provide after purchase; even if it’s not equipment related. One time, we had process-related issues and they helped us work through them.”

Davis-Standard supplies Republic Wire with complete wire and cable systems from extruder and control systems through downstream equipment, including payoffs, takeups, accumulators, cooling trough systems and multi-pass capstans. Specific to building wire, Davis-Standard has over 250 installed systems worldwide. These systems, similar to the ones installed at Republic Wire, are engineered for insulating single cores and jacketing multi-conductor insulated constructions. This technology also provides continuous operation for packaging the product in coils, reels or stem packs. This is essential for Republic Wire because the company offers a variety of packaging options to customers.

“Davis-Standard’s customer focus has evolved over the years,” added Hadley. “They are even more customer-oriented than before and this has been a big selling point for us. We know the equipment will give us the longevity we seek at the line speeds we need to stay competitive. Our Republic Wire team is one of the reasons our customers are loyal. The support of Davis-Standard’s team makes our team stronger.”

For more information about Republic Wire, visit www.republicwire.com. For more information about Davis-Standard’s wire and cable capabilities, visit www.davis-standard.com. Photo Courtesy of Republic Wire- Pictured: Dave Hadley, Plant Manager, Republic Wire.

Davis-Standard, LLC is pleased to announce the appointment of Robert Dages to Aftermarket Regional Sales Manager. In his new role, Dages will focus on aftermarket sales of converting equipment for the Wisconsin, Minnesota, and other select mid-west customers.

Davis-Standard, LLC is pleased to announce the appointment of Robert Dages to Aftermarket Regional Sales Manager. In his new role, Dages will focus on aftermarket sales of converting equipment for the Wisconsin, Minnesota, and other select mid-west customers.

Prior to joining Davis-Standard, Dages worked as Senior Vice President for the North American division of a leading converting machinery manufacturer. He also managed sales and marketing for the supply of coating and laminating lines.

“Dages brings extensive sales experience with coating and laminating processes and equipment,” said Andre Icso, Davis-Standard Vice President of Global Aftermarket Sales. “His extensive experience will prove to be an invaluable asset to our sales team.”

The Global Advantage™ offered by Davis-Standard’s converting technology and support services will be promoted at ICE Europe, Hall A5, booth #912, in Munich, Germany, March 21-23. Davis-Standard is a respected market leader in processing equipment and services for extrusion coating, liquid coating, blown film and cast film, serving customers on every continent. At ICE, Davis-Standard will highlight its liquid coating technology, along with its cost-effective, high productivity processing systems for converting applications – the dsX™ series.

The Global Advantage™ offered by Davis-Standard’s converting technology and support services will be promoted at ICE Europe, Hall A5, booth #912, in Munich, Germany, March 21-23. Davis-Standard is a respected market leader in processing equipment and services for extrusion coating, liquid coating, blown film and cast film, serving customers on every continent. At ICE, Davis-Standard will highlight its liquid coating technology, along with its cost-effective, high productivity processing systems for converting applications – the dsX™ series.

Davis-Standard’s liquid coating technology includes a curtain slide coater and a five-roll silicone coater. The curtain slide coater applies single layer coatings at rates up to 2800 fpm (853 mpm) with expansion capabilities up to two additional layers. The five-roll silicone coater is capable of applying 100 percent silicone at rates up to 2400 fpm (732 mpm). This coater is constructed of stainless steel for ease of cleanup and includes a mist removal system. Davis-Standard supports liquid coating for slow or high-speed applications, clean room environments, film or paper substrates, ultra thin and ultra thick coatings, and precision coating and drying.

In extrusion coating, Davis-Standard offers the dsX flex-pack™ to provide converters and package printers with a high-value, competitively priced system. An adaptable machine configuration gives processors the flexibility to compete in a variety of emerging application markets including salted snack and noodle bags, toothpaste tubes, personal care products, condiment packs and stand-up pouches. Production benefits include product consistency, excellent bonding strength, greater uptime and productivity, and reduced waste and production costs. The economical benefit of these 450 meter-per-minute (1,500 fpm) machines is allowing many regional converters to distinguish themselves from the competition.

Davis-Standard technology supports cast and blown film applications with the dsX s-tretch™ and dsX flex-film™ systems. The dsX s-tretch is the first cast film line of its kind featuring integrated pre-stretch capabilities as an alternative to traditional pre-stretching methods. Processors can take advantage of thinner films, higher line speeds, reduced waste and improved film strength. In blown film, the dsX flex-film is designed for applications in printing and laminating, flexible packaging, collation shrink and bag making, hood shrink and surface printing. Options for Davis-Standard’s industry-leading air ring and feedscrew designs are available as well as different widths and die sizes to accommodate multiple products.

Regional service teams support converting equipment before, during and after the sale with timely delivery and installation, readily available spare parts and prompt customer service. This includes service and support for Davis-Standard’s line of control systems. Davis-Standard’s Circonix Technologies Division offers upgrades of PLC, drive and mechanical systems on thousands of existing installations, including non Davis-Standard brands. For more information, visit www.davis-standard.com.