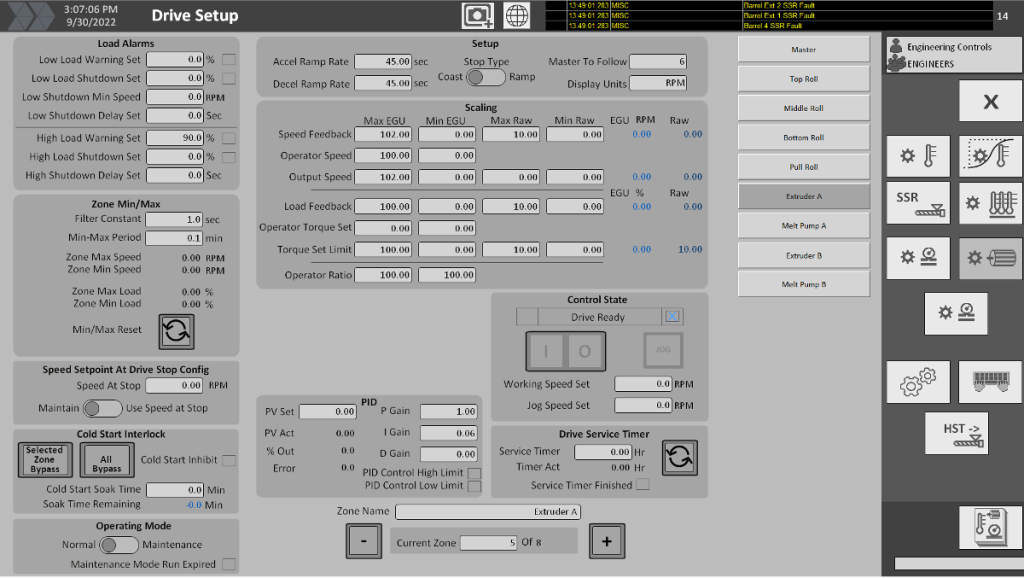

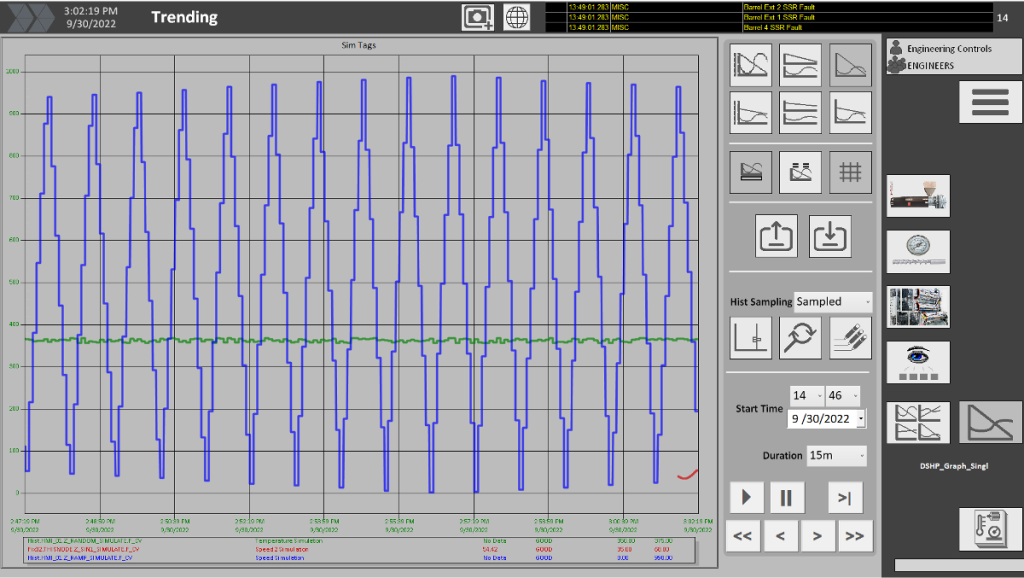

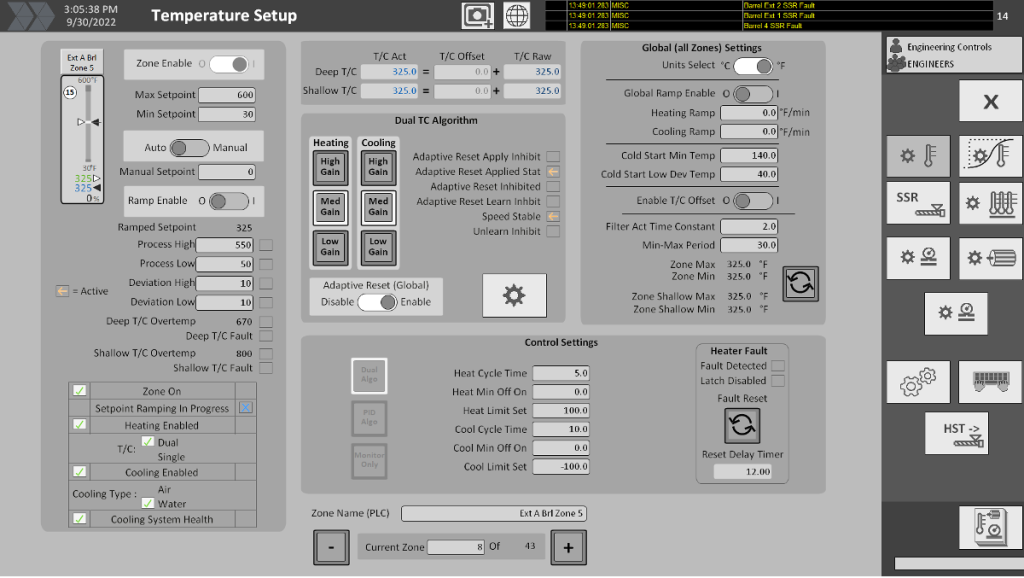

The next generation of Davis-Standard’s supervisory control technology is here – introducing the EPIC IV®. This control system builds upon the comprehensive, user-friendly approach of the EPIC III® while enhancing the operator’s experience and adding connectivity to Davis-Standard’s cloud-based solution, DS Activ-Check™. Advantages include improved graphics and symbols, additional diagnostic and efficiency tools, and screens focused on active functions and alerts.

“The EPIC IV® uses a high-performance HMI approach to strengthen the operator’s experience,” said John Clemens, Davis-Standard’s Director of Extrusion Controls. “The new color scheme focuses operator attention on active functions and alerts while also assisting operators with color vision deficiency by using shapes to indicate machine status. Overall, this will be a better supervisory control package for global installations moving forward.”

The updates seen in EPIC IV® reflect customer feedback and a commitment to digital transformation via DS Activ-Check™. The “smart” technology of DS Activ-Check™ enables real-time predictive maintenance by providing early notifications of potential machine failures. As a result, operators are alerted to issues before they happen, reducing unplanned downtime and collecting valuable data in sync with EPIC IV® control features. Users receive notifications via e-mail or text, and continuous monitoring of production machine status is available on smart devices and remote PCs. Key parameters monitored include extruder reducer, lubrication system, motor characteristics, drive power unit, barrel heating and cooling functions.

The EPIC IV® will replace the EPIC III® as the standard offering for supervisory control on all new Davis-Standard extruders. It will also be available as an upgrade for existing EPIC supervisory control systems.

For more information about the new EPIC IV® or to request a quote, contact us today.