Building upon our last wire and cable blog on capstan technology, we’ll cover the most significant reel handling components of a wire and cable line – takeups and payoffs. These machines are used for winding and unwinding wire and cable for SZ stranding, secondary coating, sheathing and insulation. Davis-Standard and Maillefer, a Davis-Standard company, offer several models of takeups and payoffs to support wire and cable applications including fiber optic, low-voltage and telecom cable, building wire, MV, HV and EHV wire. Machine selection depends on factors such as reel weight, flange diameter, cable diameter, automation features and line speed requirements. Reel handling equipment also includes dancers, cutters and optical traverse control, which can be incorporated into a reel handling package.

Following is a brief summary of the different types of takeups and payoffs and typical applications:

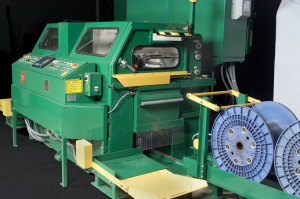

Dual reel take-ups: This design offers changeover reliability for any application at top-line speeds. These speeds can be upward of 9,500 feet (2,896 meters) per minute and for reels up to 50 inches (1,270mm) in diameter and 5,000 pounds. Operation can be fully automatic with various reel handling options, or semi-automatic, requiring tending only for loading and unloading of reels. These machines can work independently from line controls for easy adaptation and installation.

Applications: Automotive wire, building wire, low-voltage wire

Flyer pay-offs: Excellent for high-speed and uninterrupted continuous wire unwinding with constant tension required for cable insulation. These machines are comprised of two conical fly-off cones, two-reel lifting carts (displaceable over rails), one pair of fly-off flanges and one pair of reel shaft adapters.

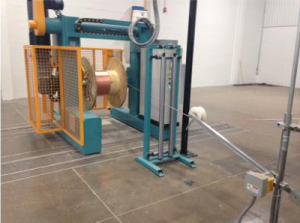

Floor traversing take-ups and pay-offs: These shaftless models offer space-saving, low profile construction to support heavy loads and a broad reel range due to the capacity to extend production lengths. These machines can be equipped with low, medium and high tension dancers, with mechanical or electrical braking and reel engagement, and various options for reel loading and unloading.

Moveable arm take-ups and pay-offs: Also referred to as PORA/TURA take-ups and pay-offs, these models are shaftless in design with pneumatic reel lift or dual-electric screw jack actuators on 84 to 120-inch (2,100 to 3,000mm) units. Larger units use independent arm movement for reel arrangement while single actuation capabilities are supplied on models 36 inches and smaller.

Applications: Low voltage wire, MV, HV and EHV

Portal take-ups and pay-offs: These machines are ideal for heavy loads and a wide reel range. They are built with a shaftless roll-thru design that allows reel loading from the rear or front of the machine. The frame can be supplied in single, double or triple widths to support flange diameters of 42 to 144 inches (1,066 to 3,600mm), weighing up to 60,000 pounds. All functions such as reel rotation, traversing, pintle movements and auto reel handling are activated and controlled from a hanging control panel.

Applications: Building wire, fiber optic cable, low voltage wire, MV, HV and EHV

Have a question regarding this blog? Comments below! We would love to hear from you.

E-mail marketing at marketing@davis-standard.com to let us know how we can help you evaluate extrusion line components or seek to upgrade a current line.

Cheers,

The D-S Connect Blog Team