Looking for a high output reprocessing solution? Davis Standard’s extrusion capabilities for reprocessing combine innovative technologies for recycling the waste stream into a reusable product.

Our range of single screw and twin screw compounding and reprocessing systems address key efficiency factors such as: solids feeding and conveying, venting and devolatilization, compression and melting, polymer homogenization, and process controls.

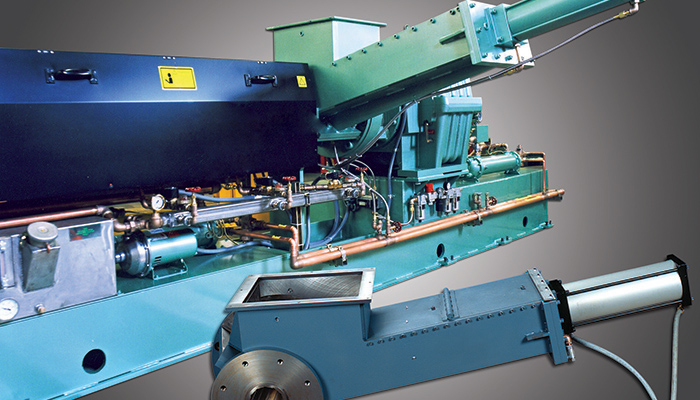

Within our extrusion recycling technology line is scrap-reclaim and wide-mouth feed technology, ram stuffer and scrapper extruder options and complete reclaim systems. Heavy-duty gear reducers, customized feed throats, single or multi-venting options and process feed systems are just a few ways we can give you a competitive advantage.

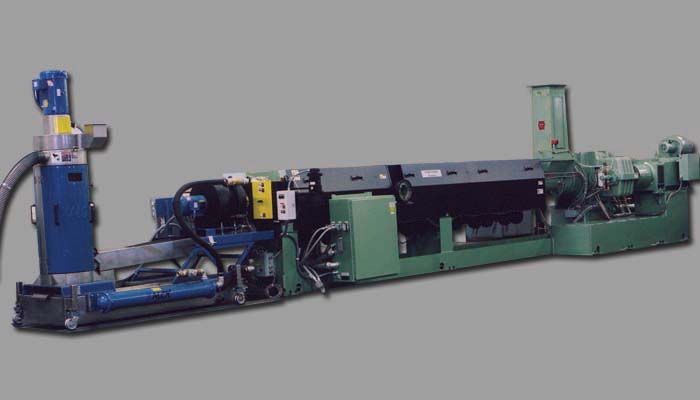

In the area of extrusion technology for film reprocessing, Davis-Standard supplies extrusion systems that offer versatility for turning low bulk density film waste into a useable product. Extrusion systems typically include the extruder, a melt filtration device, pelletizing unit and material handling system. Material size reduction and transfer conveyors can be customized depending on application. Our relationships with major melt filtration and pelletizing suppliers ensure system continuity.

Our Ram Stuffer extruder model is specifically designed for processing the broadest range of feed stocks. This includes everything from light bulk density fluff to shredded flakes, and even heavy bulk density, regrind materials. The Ram Stuffer extruder uses a pneumatically actuated plunger to force the material into the feed section of the screw. The feed section has grooved technology to enhance the conveying of the feed material into the extruder barrel. In a similar way, our scrap reclaim extruder model uses the same wide mouth feed throat design as the Ram Stuffer without the pneumatic plunger. This affords a lower cost alternative when the feed material is slightly heavier in bulk density.

Typical Specifications

Applications - Stretch wrap, agricultural film, construction film, packaging film, general films, barrier and non-barrier, mono and multilayer films

Bulk Density - 32 to 400 kg/m3 / 2 to 25 lbs/ft3

Materials - Polyethylene, Polypropylene

Extruder Outputs - Up to 2700 kg/hr / Up to 6000 lbs/hr

Features - Wide range of line equipment solutions to suit customer's requirements and budgets, latest controls systems, full lines and systematic upgrade/retrofits

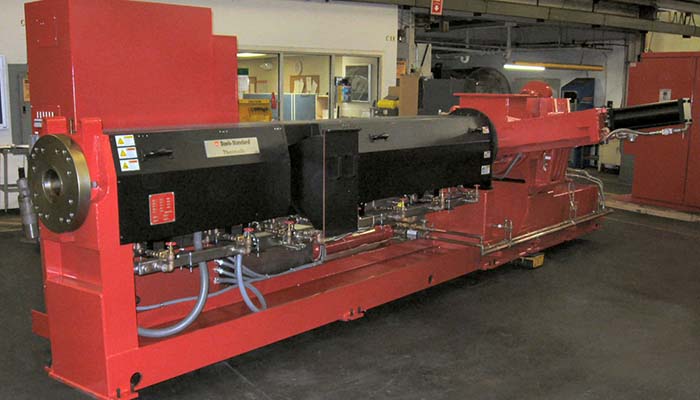

Davis-Standard supports the foam producer or recycler with innovative engineering and proven extrusion technology. Our extruders accommodate different requirements for reprocessing/recycling low bulk density foam waste into a reusable product in a cost-effective manner. We have relationships with major suppliers in the melt filtration and pelletizing market to provide integrated solutions.

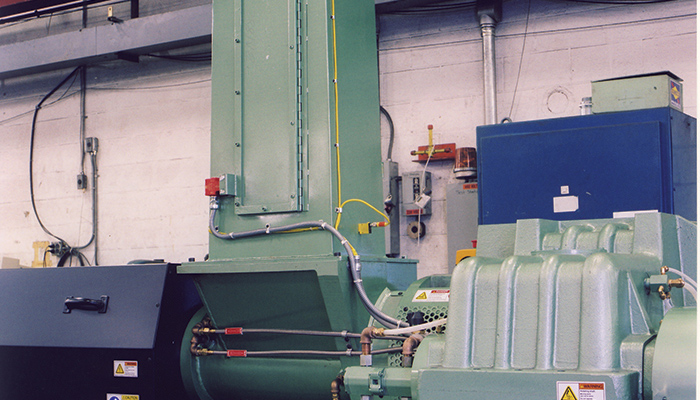

Our signature Scrapper dual diameter extruder model is specifically designed to process low bulk density feed stocks, typically from XPS board shavings and millings. The Scrapper uses a large diameter feed section to allow this product to be processed at the highest output rates. This extrusion design incorporates grooved feed technology to more efficiently convey the feed material into the extruder barrel. As a lower cost alternative, we offer a foam scrap reclaim extruder for processing materials with a heavier bulk density such as thermoformed meat trays, plates and cups. These machines incorporate a tangential feed section and also use grooved feed technology to ensure efficient processing.

Typical Specifications

Applications - Foam board, foam sheet, edge regrind, thermoforming skeletons, roll waste

Bulk Density - 48 to 190 kg/m3 / 4 to 12 lbs/ft3

Materials - Polystyrene, Polyethylene, Polypropylene

Extruder Outputs - Up to 1000 kg/hr for the Scrapper and foam scrap reclaim units / Up to 2000 lbs/hr for the Scrapper and foam scrap reclaim units

Features - Wide range of line equipment solutions to suit customer's requirements and budgets, latest controls systems, full lines and systematic upgrade/retrofits

Davis-Standard’s reprocessing capabilities combine innovative extrusion technology with multiple options for reprocessing/recycling the waste stream into a reusable product. Our extruders are available in several designs to accommodate a wide variety of waste materials and add profitability to your operation. We supply specialty designs for low bulk density materials as well as more traditional designs to allow processing of irregular shaped chip, flake and regrind.

Our reclaim extruder models are capable of processing bulk density feedstocks, typically from injection molding, blow molding, sheet production and thermoforming processes. An oversized feed section allows irregular shaped feedstock to be processed at the highest possible output rates. We have several design options which enable us to optimize the extrusion system for a given material and application.

Typical Specifications

Applications - injection runners, foam sheet, edge regrind, thermoforming skeletons, roll waste

Bulk Density - 48 to 190 kg/m3 4 to 12 lbs/ft3

Materials - Polystyrene, Polyethylene, Polypropylene

Extruder Outputs - Up to 1000 kg/hr for the Scrapper and foam scrap reclaim units / Up to 2000 lbs/hr for the Scrapper and foam scrap reclaim units

Features - Wide range of line equipment solutions to suit customer's requirements and budgets, latest controls systems, full lines and systematic upgrade/retrofits