Flexible and Customized Extrusion Control Solutions for Every Process

- DS-eTPC touch-screen control

- DS-Tablet hand-held operator interface

The brain of the extruder drives your operation and smarter process controls make a huge impact on the bottom line. That is why every system in Davis-Standard’s full line of process controls is operator-friendly, efficient and reliable. From discrete to full supervisory control, our control systems are engineered in-house to ensure quality and value.

The signature EPIC III® and Integrator controls, the portable DS-Tablet and affordable DS-eVUE are just a few of our technologies that take the guesswork out of your extrusion operation. Davis-Standard’s proven systems do the thinking for you about systems integration, temperature control and process controls.

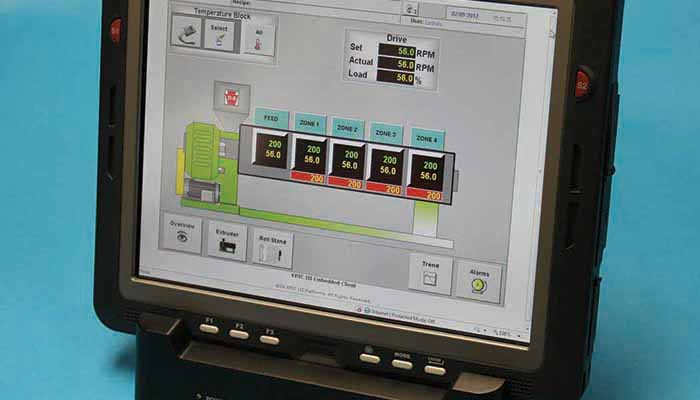

Davis-Standard's EPIC III® is an advanced Windows®-based touch screen extrusion process control system offering complete plant management and process control capabilities. Advantages include:

- Adaptable and expandable touch screen displays

- Supervisory features: event logging, customized reports, SQC, historical trending, maintenance/troubleshooting, pressure set-up and more

- Partial and complete line overview, detailed extruder data, recipe creation/storage, etc.

- iFIX™ SCADA software for Windows®

- ControlLogix™ PLC platform (optional Siemens S-7)

- Connectivity solutions for remote data access via laptop and Web browsing

- Object linking and embedding for process control

- A multiple-level security system to protect set-up functions and accessibility

- Network capability for remote monitoring of multiple systems

- Available DVD writer and removable hard drive for secure system data back-ups

Davis-Standard’s EPIC IV® integrates a high performance HMI experience with supervisory control for complex systems. With Windows®-based plant management and extensive process control capabilities, the EPIC IV can be customized for any extrusion or converting application. Supervisory features include alarm and event logging, customized real-time reports, SQC, historical trending, data collection, maintenance/troubleshooting help files, calibration, tuning, and more.

- iFIX SCADA software for Windows®

- Premium connectivity solutions enable the EPIC to communicate with a wide variety of third party equipment.

- ControlLogix PLC platform standard

- Best-in-class historian software solution that collects, stores, and retrieves data efficiently and securely

- ReACT - Remote access for service and support - requires an Internet connection

- Multi-level security system to protect set-up functions and accessibility

- OPC UA server available for MES/ERP connectivity.

- Multi-Language support for global availability

- Adaptable and expandable touch-screen displays

- Machine KPI data clearly displayed on line overview and control screens that are customized to match the specific application

The DS-eVUE combines many features of the EPIC III® with the low-cost requirements of previous HMI applications. Features include:

- 15-inch widescreen

- Graphics overview

- Reports

- Trending

- Event log

- Data collection

- WEB interface (2 concurrent users)

- Email notifications

- FDA-21 Part 11 ready

- Electronic signatures

The DS-eTPC (touch panel control) offers comprehensive integrated touch-screen control with attractive pricing. Advantages include:

- Coordinated line drive control (standard feature)

- Operator friendly design

- Cold start inhibit

- High and high-high alarms for each pressure point

- Recipe creation and storage

- Provision for system networking to a supervisory computer via Ethernet LAN

- Pre-configured and engineered levels with added temperature and line control options

- Optional closed loop pressure control for melt pump operation, additional line drive and heat zones

- Optional line drive

The DS-XEL control system is the new standard for extruder controls. The XEL features a high performance design approach that helps users be more productive by highlighting extruder key performance data and streamlining operating

features. It also supports connectivity to supervisory systems to allow users to collect real-time data for their manufacturing execution system (MES) or asset performance management (APM) systems.

High-performance HMI design philosophy for enhanced operator experience. Allows operators to focus on relevant controls and data.

- Built in security to prevent unauthorized changes to system setup parameters.

- Multi-Language support built in.

- OPC-UA for easy supervisor system connectivity.

- Safety integrated into the PLC control system.

- Process alarm logging.

- Real time and historical trending.

- Data logging

- Recipe creation for product repeatability.

- IIoT licensing MQtt protocol

- Heater zone alarming – deviation, process, power fail, load fail, T/C break

- Monitoring of individual zone heater current draw

- Auto and Self tuning options per zone

- Extruder maintenance run timer

- Bar graph display of speed deviation from setpoint

- Min/Max and average motor load during a run

Davis-Standard’s hand-held operator interface – the DS Tablet – is a convenient option available with the EPIC III® (iFIX) system. It features:

- 10.4-inch touch-screen

- Wireless connection to EPIC III®

- Windows embedded software

- Docking station, USB ports, charger, and solid-state drive

- Rugged design for industrial environment

- Operator access functions while in areas not practical for typical OCS locations

- Concurrent remote viewing of EPIC III® on office PC with Internet Explorer®

Other advantages of the DS Tablet include:

- A process control screen similar to the EPIC III®

- Temperature screens to change set-point

- Line control screens to change drive set-points

- Ability to create, select and view historical trend groups (historical data is stored on the EPIC III®)

- Viewing and acknowledgment of new and current alarm settings

- Print reports at the EPIC III®

- Security for engineer, supervisor and operator groups

Using the ReACT support system customers can enjoy high-speed remote troubleshooting support from Davis-Standard via a secure Internet connection. This system provides real-time viewing and control of EPIC III® screens and PLC systems without affecting the current application. It also provides a faster response to customer needs regarding EPIC III®/PLC controls or process issues.

- Uses standard Internet Explorer®

- Service is intended for troubleshooting and process support

- Works using a third hard drive, which is connected by the customer when support is needed

This cost-effective system, an upgrade from the MACO® 6500RS introduced in 2005, is available for retrofit to existing systems. It offers a number of enhancements including screen updates nearly three times faster than older systems. The Operator’s Graphical User Interface has been upgraded to Wonderware® 8.0 and Windows® XP Professional that communicate with the PLC over two separate servers instead of one. This allows for transmission of set points over one server while values are transmitted over another, saving time and improving functionality.

Other significant upgrades include machine screens in several languages, an upgraded setpoint change log to track changes made by the machine operators, a Statistical Process Control program to continuously track 34 items each cycle, and a recipe “save” function to verify recipe names and eliminate the potential for lost recipes. A new “Heat Soak” feature reduces the chances for a cold start-up by requiring machines to be above the low-temperature alarm for at least two hours before the extruder and head tooling programming hydraulics will run. In addition, now both the PLC and Operator’s Station have an uninterruptible power supply to keep them from shutting off during momentary power failures.

As with the MACO® 6500RS, this system includes closed-loop synchronous shoot/fill, adaptive speed control and a PLC ladder logic that can be viewed in real time. Davis-Standard also offers a range of on-site training programs as well as 24/7 telephone service. Especially advantageous is the availability of real-time computer-direct machine service through the Internet.