Leading Technology and Innovation for Your Elastomer Extrusion Requirements

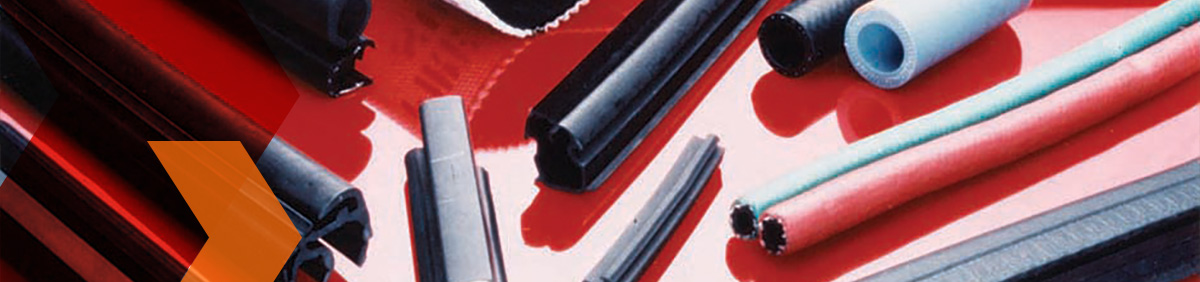

Davis-Standard’s elastomer extruders support global markets for tires, automotive hoses, adhesives and sealants, recreational equipment, construction and medical applications. We are industry leaders in complete rubber and silicone technology to support a range of applications including rubber hose, rubber and silicone gaskets, rubber barrier products, silicone tubing and weatherstrip.

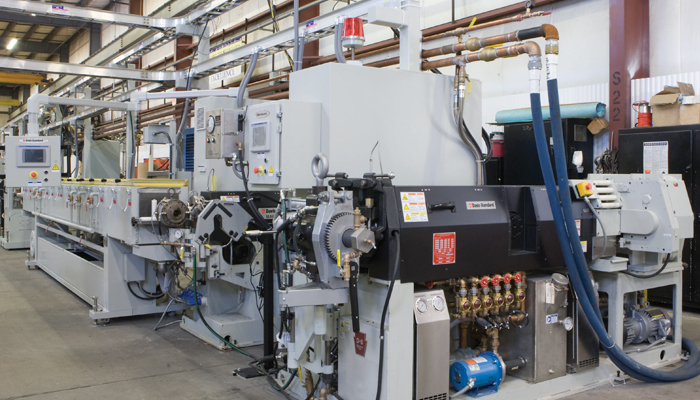

With elastomer extruders in multipurpose, hot and cold feed, silicone, vacuum vented, pin barrel and smooth barrel designs, our extensive offering of elastomer systems provides a specific solution for nearly every elastomer application. Our engineers work with you to supply elastomer equipment that meets your precise product requirements, including technology for product curing and in-line processing.

Our advantage lies in decades of experience and knowledge of elastomer properties and processes for coextrusion, rubber straining and continuous vulcanization. That is why we also supply custom feedscrew designs, lab equipment, integrated process controls and complete systems—one-stop shopping for turnkey rubber extrusion.

Davis-Standard has years of experience supplying elastomer extruders, components, and complete systems for automotive seals. Our elastomer customer base is Tier 1 with installations worldwide. We supply duplex, triplex and quadruplex profile heads for supported and unsupported rubber profiles. We are industry leaders in turnkey applications including carrier forming, curing, coating, flocking and cutting/sawing of profiles.

We understand the importance of each component and offer a wide range of Davis-Standard-built and Davis-Standard-specified elastomer equipment with experienced partners. This includes hot air and microwave curing ovens, pre-and post-formers for rigid carrier, flocking booths, cooling tanks, pullers, cutters, laser marking, printing and drilling.

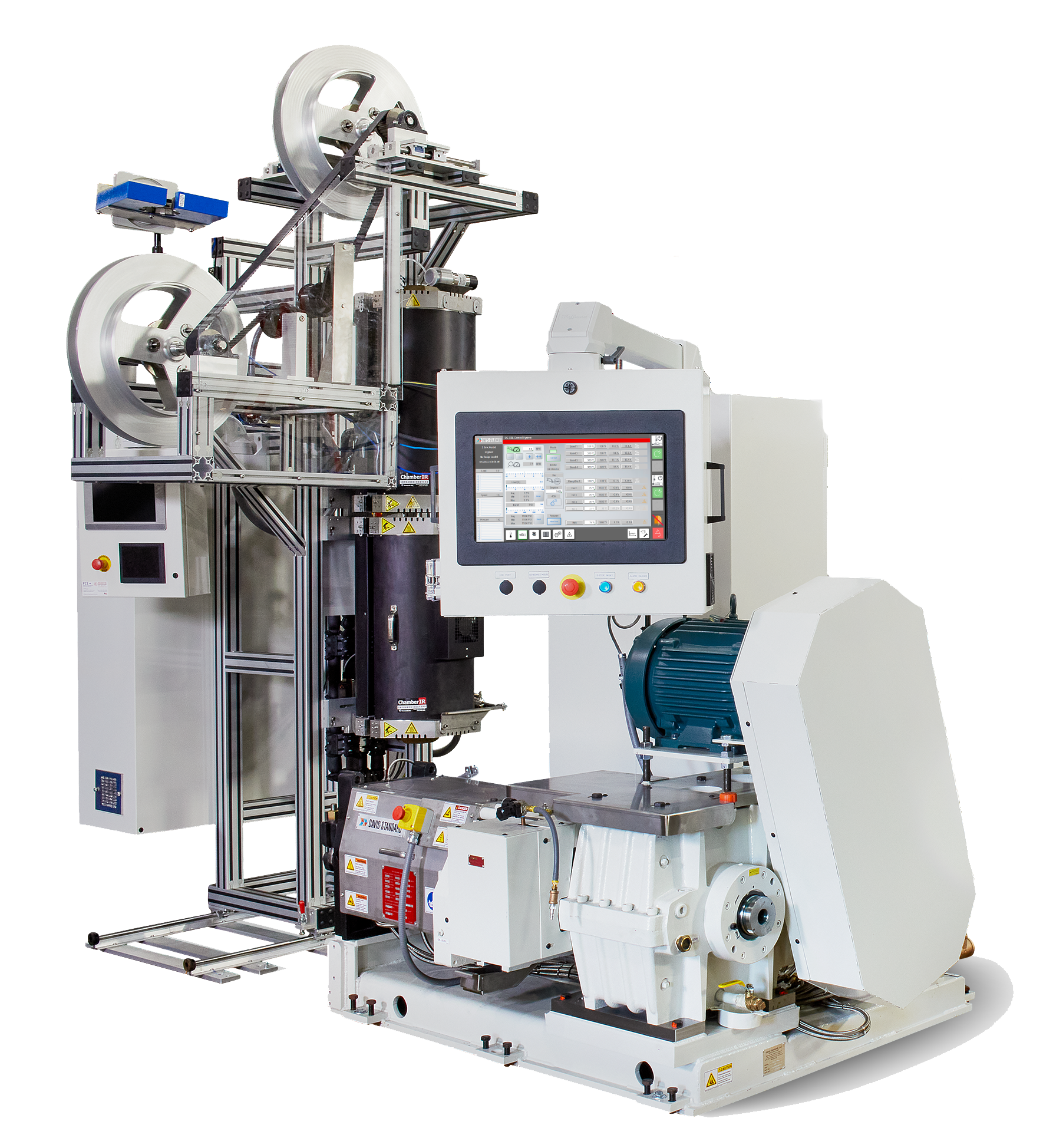

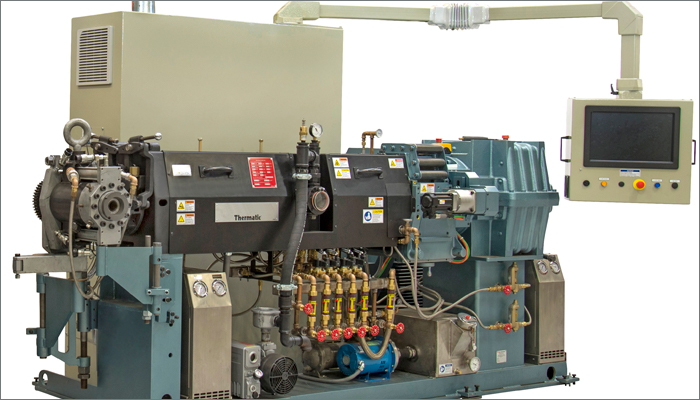

An example of our advanced elastomer technology is our purpose-designed DSREV rubber extruder. Advantages include our patented pneumatic roll feed system to provide uniform, consistent feed rate; electric heat/water-cooled heating for quicker response time, lower maintenance and smaller machine footprint, rugged Davis-Standard gearboxes, and Davis-Standard's proven feedscrew designs to maximize output and minimize scorch.

Typical Specifications

Applications - Single and dual durometer unsupported seals, single and dual durometer supported seals, wire, stamped steel, breakable steel, and rigid steel supported seals

Line Speed Range - 6 to 30 mpm / 20 to 100 fpm

Size Range - 25 to 56 square cm / 1 to 9 square inches

Materials - EPDM Sponge, EPDM Dense, TPV/EPDM Compositions

With elastomer installations worldwide, Davis-Standard offers vast experience in supplying extruders, components, and complete systems for industrial rubber hose. We understand the importance of each component and offer a wide range of Davis-Standard-built and Davis-Standard-specified equipment with experienced partners. This includes laser and x-ray gauge control, pullers and cutters, textile reinforcement, cooling and anti-tack application tanks, adhesion-promoting systems, anti-tack dusting systems, laser-marking, printing and winding.

Examples of our preferred elastomer technology in this area include:

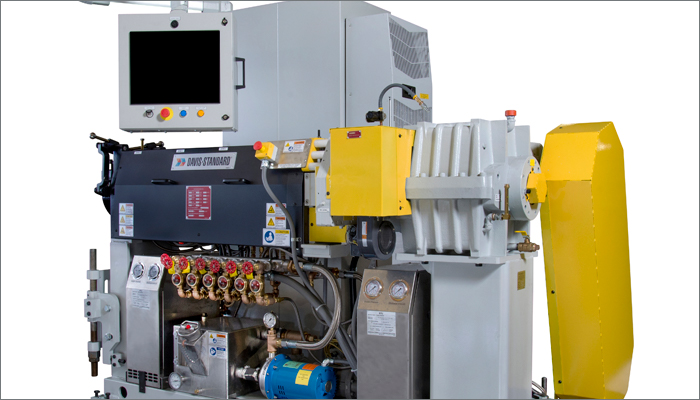

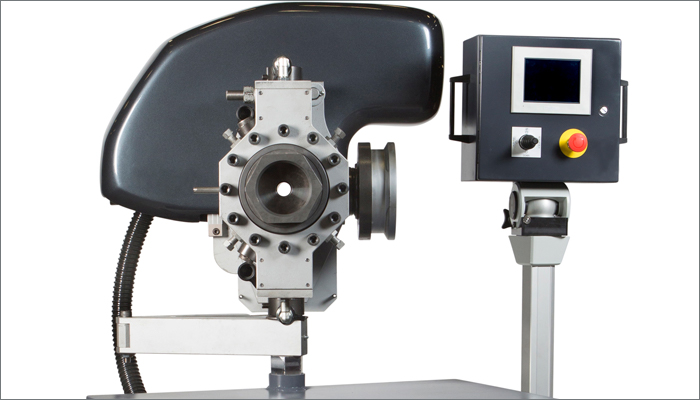

The DS Model 2000 crosshead – Features a tapered mandrel and highly engineered flow paths to ensure equal flow through all line speed ranges; propriety coating on wetted surfaces to increase wear resistance and provide easier clean-out; thrust bearing on pin adjustment to allow wall thickness adjustment without stopping the line; and hydraulic cylinders for quick and easy removal of the mandrel from the head body.

The DSREV rubber extruder – Features our patented pneumatic roll feed system to provide a uniform, consistent feed rate; electric heat/water-cooled heating for quicker response time, lower maintenance and smaller machine footprint; rugged Davis-Standard gearboxes; and proven feedscrew designs to maximize output and minimize scorch.

Typical Specifications

Applications - Composite spiral reinforced hose, composite knit reinforced hose, pole-built, 2-step wire reinforced hydraulic hose, multi-layer specialty fuel/gas hose

Line Speed Range - 1.5 to 100 mpm / 5 to 30 fpm

Size Range - 6 to 115mm / 250 to 4.5 inches

Materials - EPDM, NBR, SBR, FKM, ECO, THV, silicone

Our elastomer systems and rubber extruders for automotive hose are widely used among Tier 1 customers worldwide. We understand the importance of each component and offer a wide range of Davis-Standard-built and Davis-Standard-specified equipment with experienced partners. This includes laser and x-ray gauge control, pullers, cutters, textile reinforcement, cooling and anti-tack application tanks, adhesion-promoting systems, laser marking and printing.

Examples of our preferred technology in this area include:

The DS Model 2000 crosshead – Features a tapered mandrel and highly engineered flow paths to ensure equal flow through all line speed ranges; propriety coating on wetted surfaces to increase wear resistance and provide easier clean-out; thrust bearing on pin adjustment to allow wall thickness adjustment without stopping the line; and hydraulic cylinders for quick and easy removal of the mandrel from the head body.

The DSREV rubber extruder – Features our patented pneumatic roll feed system to provide uniform, consistent feed rate; electric heat/water-cooled heating for quicker response time; lower maintenance and smaller machine footprint; rugged Davis-Standard gearboxes; and proven feedscrew designs to maximize output and minimize scorch.

Typical Specifications

Applications - Coolant hose, radiator hose, multi-layer THV/elastomer non-permeation fuel hose, A/C hose, turbo charger hose, brake hose

Line Speed Range - 1.5 to 30 mpm / 5 to 100 fpm

Size Range - 6 to 115 mm / .250 to 4.5 inches

Materials - EPDM, NBR, SBR, FKM, ECO , THV, silicone

We supply elastomer extruders, components, and complete elastomer systems for large and small continuous cure gasket lines for both rubber and silicone products. We understand the importance of each component and offer a wide range of Davis-Standard-built and Davis-Standard-specified equipment with experienced partners. This includes hot air and microwave curing ovens, salt bath curing tanks, standard and custom cooling tanks, pullers, cutters, laser marking, printing and winding.

An example of our advanced elastomer technology is our purpose-designed DSREV rubber extruder. Advantages include our patented pneumatic roll feed system to a provide uniform, consistent feed rate; electric heat/water-cooled heating for quicker response time; lower maintenance and smaller machine footprint; rugged Davis-Standard gearboxes; and Davis-Standard's proven feedscrew designs to maximize output and minimize scorch.

Typical Specifications

Applications - Coolant hose, radiator hose, multi-layer THV/Elastomer non-permeation fuel hose, A/C hose, turbocharger hose, brake hose

Line Speed Range - 1.5 to 30 mpm / 5 to 100 fpm

Size Range - 6 to 115mm / .250 to 4.5 inches

Materials - EPDM, NBR, SBR, FKM, ECO , THV, silicone

Davis-Standard has extensive process and extrusion expertise in the area of medical and industrial silicone tubing worldwide. We understand there is a difference between extruding an industrial fluid transfer tube and extruding an infantile catheter. Our engineers work with you to supply the correct customized equipment to meet your precise product requirements including horizontal or vertical extrusion, short-wave or medium-wave cure systems, custom designed dies and downstream equipment, or precision cutting and winding.

An example of our preferred extrusion technology in this area includes our DSR silicone extruder. Advantages include our patented pneumatic roll feed system to provide uniform, consistent feed rate, chrome plating and stainless steel contact surfaces for medical environments, available hinge-roll feed roll section for easy cleanout and compound changes, rugged Davis-Standard gearboxes, and proven feedscrew designs to maximize output and stability.

Typical Specifications

Applications - Medical silicone catheters, wound drainage tubing, specialized tubing, Medical silicone tubing (multi-lumen), radio-opaque stripe, farm/dairy silicone tubing and multi-layer hose, industrial silicone tubing, specialty silicone gaskets

Line Speed Range - 1.5 to 23 mpm / 5 to 75 fpm

Size Range - 2.5 to 50mm / 100 to 2 inches

Materials - Medical and industrial grade silicone compounds, heavily filled, conductive silicone compounds

- Tapered mandrel designed for stable concentricity

- Engineered flow path through head maintains equal flow across speed ranges

- Rigid die holder maintains concentricity adjustment when dies are changed

- Die adjusting screws are in removable inserts to protect body from thread damage

- Thrust bearing allows easy pin adjustment to change wall thickness

- Larger surface area in water jacket for better heat transfer

- Manufactured from AISI 4140 heat treated steel with all inside surfaces coated with Armalloy for improved wear resistance, material flow, and clean-out

- Hydraulic mandrel removal with air operated hydraulic pump and control valve

- Mandrel swings/slides out

- Standard models available to cover 2” (50mm), 3” (76mm), 4.5” (102mm) and 5.5” (140mm) diameter braid

- 2” and 3” models include pintle mount on a Davis-Standard hinge and scissor-arm support for mandrel removal; 4.5” and 5.5” model includes support cart with mandrel removal facilitated by linear rails on the cart

The Model 3000A incorporates an automatic, servo-driven concentricity adjustment system. This new, proprietary system allows for adjustment of the core tube/tip assembly with simple, accurate joystick control. This enables the operator to easily minimize eccentricity, maximize concentricity, and reduce downtime during product changeovers. In addition, the servo drives enable monitoring and adjustments throughout the run to account for lot-to-lot variations, day/night variations, and gum space corrections. The compact design does not require a hydraulic pump system or hoses.

- Tapered mandrel designed for stable concentricity

- Engineered flow path through head maintains equal flow across speed ranges

- Rigid die holder maintains concentricity adjustment when dies are changed

- Die-adjusting screws are in removable inserts to protect body from thread damage

- Thrust bearing allows easy pin adjustment to change wall thickness

- Larger surface area in water jacket for better heat transfer

- Manufactured from AISI 4140 heat treated steel with all inside surfaces coated with Armalloy for improved wear resistance, material flow, and clean-out

- Hydraulic mandrel removal with air-operated hydraulic pump and control valve

- Mandrel swings/slides out and is supported for safe and easy cleaning

- Standard models available to cover 2” (50mm), 3” (76mm), 4.5” (102mm) and 5.5” (140mm) diameter braid

- 2” and 3” models include pintle mount on a Davis-Standard hinge and scissor-arm support for mandrel removal

- 4.5” and 5.5” models include support cart with mandrel removal facilitated by linear rails on the cart

The Model 4000AG incorporates an automatic, servo-driven concentricity and wall thickness adjustment system. This new, proprietary system allows for adjustment of the core tube/tip assembly with simple, accurate joystick control. This enables the operator to easily minimize eccentricity, maximize concentricity, and reduce downtime during product changeovers.

In addition, the servo drives enable monitoring and adjustments throughout the run to account for lot-to-lot variations, day/night variations, and wall thickness corrections.

The compact design does not require a hydraulic pump system or hoses. This system also includes stepper-driven wall thickness adjustment, eliminating the requirement of hand tools and intrusive thickness measuring devices.

Additional features such as a tapered mandrel and highly-engineered flow paths ensure consistent flow through all speed ranges. Heat transfer efficiency has been optimized by using computer analyzed software for design of water-cooling jacket.

Models are available to accommodate 2-inch (50mm), 3-inch (76mm), 4.5-inch (102mm) and 5.5-inch (140mm) diameter braids.

- Tapered mandrel designed for stable concentricity

- Engineered flow path through head maintains equal flow across speed ranges

- Rigid fixed die holder maintains concentricity adjustment when dies are changed

- Slew Ring allows easy pin adjustment to change wall thickness via spring center return toggle switch

- Enhanced water jacket design for better heat transfer

- Manufactured from AISI 4140 heat treated steel with all inside surfaces coated with Armalloy for improved wear resistance, material flow, and clean-out

- Hydraulic mandrel removal with air-operated hydraulic pump and control valve

- Mandrel swings/slides out and is supported for safe and easy cleaning

- Standard models available to cover 2-inch (50mm), 3-inch (76mm), 4.5-inch (102mm) and 5.5-inch (140mm) diameter braid

- 2 and 3-inch models include pintle mount on a Davis-Standard hinge and scissor-arm support for mandrel removal

- 4.5-inch and 5.5-inch models include support cart with mandrel removal facilitated by linear rails on the cart

- Most existing Model 2000 and 3000 heads can be retrofitted to take advantage of the Model 4000AG automated design features (X-Ray gauge and controller is required to provide a signal back to the Davis-Standard PLC Controller)