In this second blog post of our blown film series, Laura Martin, Director of Blown Film Technology at Brampton Engineering, explains the basic characteristics of key resins used in blown film structures.

Multilayer films require various resins to achieve specific properties in the final structure and also to improve processability during film production and converting. Choosing these resin grades is also about balancing raw material cost, typically accounting for 80 percent of the overall cost of making film! Different resin families and grades enable functions such as barrier, sealing, adhesion, stiffness, toughness, formability, and simply making up the bulk of film thickness.

Polyethylene (PE)

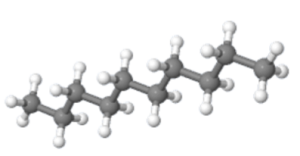

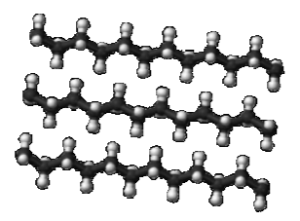

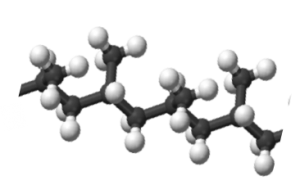

All types of PE are chemically identical: a wide range of processing and product properties results from different forms of branching, crystallinity levels and densities.

- PE is the basis of most coextruded blown film structures

- Used in sealant layers and in-forming film bulk

- Often blended together to optimize property profiles, processability and cost

- Excellent chemical resistance

High-density PE (HDPE)

This resin produces a stiffer barrier film that offers moisture protection to keep products dry and fresh.

- Highest density of the PE types due to lack of branching and high crystallinity levels – packs well in a 3-D array

- ρ = 0.93-0.97 g/cc

- Process temperature is roughly 220°C

- Used in bulk or outside layers

- Good water vapor barrier – protects EVOH

- Moderate stiffness and toughness

- More haze (due to crystallinity)

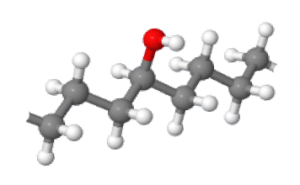

Low-Density PE (LDPE)

For clear, abuse-resistant films, which are easier to process and use on packaging lines.

- p = 0.91-0.93 g/cc due to high degree of long-chain branching and low crystallinity (doesn’t pack well)

- Process temperature is roughly 210°C

- Used in bulk or sealant layers

- Superior clarity, toughness, dart impact strength

- Good seal and hot tack strength, low seal initiation T

- Long branches improve melt strength in blends

Linear Low-Density PE (LLDPE)

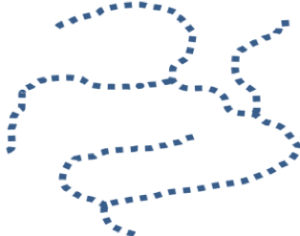

These are the lowest cost grades with a good balance of properties but can be difficult to process without the right equipment.

- p = 0.91-0.94 g/cc with many short branches and low crystallinity levels

- Process temperature is roughly 220°C

- Used in bulk and sealant layers

- High strength, good low-temperature properties, low shrink temperature

- More difficult to process (low shear-thinning)

Metallocene PE (mLLDPE)

Similar to LLDPE, but made via a different catalyst chemistry (metallocene), resulting in more precise chain lengths and branching. Resin producers can fine-tune grades for specific applications, and new tailored grades are now available for niche needs. For the most common mLLDPE grades:

- Process temperature is roughly 225°C

- Improves properties over similar LLDPE

- Improves optics (clarity, gloss)

- Better sealing properties

- Can be more difficult to process (low shear-thinning)

Polypropylene (PP)

Excellent clarity and moisture barrier, with better heat resistance than PE – often used on the outside of a barrier film for liquids, to permit higher sealing bar temperatures and better seals.

- p = 0.90-0.91 g/cc

- Process temperature is roughly 230°C

- Used in bulk or outside layers

- Good water vapor barrier, with much better optical appearance than PE

Polyamide Family – Nylons (PA)

Just like polyethylenes, nylons can be designed to bring a wide range of properties to films. PAs are used for robust, thermoformable barrier films with good stiffness and puncture resistance. New terpolymer grades are available to solve processing issues that can arise due to high density and low melt strength.

- p = 1.12-1.15 g/cc

- Barrier for oxygen, oil and flavors

- Stiff, strong, tough, formable, seal bar release

- PA6 – better O2 barrier, poorer H2O barrier, 250°C

- PA6/66 – clearer, better physical properties, 240°C

- Amorphous PA – blend <20% with PA6 or PA6/66 for better clarity and moisture resistance (retain barrier)

Ethylene Vinyl Alcohol Family (EVOH)

Excellent barrier to oxygen, oils, and aromas – if kept dry.

- Copolymers with varying Vinyl Alcohol content to adjust barrier properties

- Process temperature is roughly 220°C

- Always used in core layers

- Adheres to PA and tie resins, but not PE

- Minimum five layers: PE/tie/EVOH/tie/PE

- Often coextruded between two layers of PA: PE/tie/PA/EVOH/PA/tie/PE

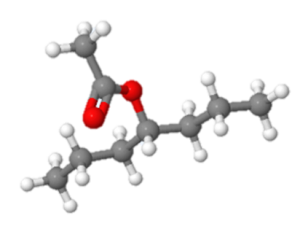

Ethylene Vinyl Acetate (EVA)

This sticky copolymer resin with adjustable properties is usually coextruded as the inner (sealant) or outer layer.

- Physical properties vary with VA content

- Process temperature is roughly 190-200°C

- High clarity, flexibility, low seal initiation temperature, good adhesion, impact and puncture resistance

Tie Layers

Tie layers enable chemically dissimilar materials to be “tied” together.

- Many different modified polymers or blends can function as tie layers between resins which do not adhere to each other

- Must have either backbone or functional groups which are compatible with each resin

- Can be preformulated or supplied as concentrates to be blended with a primary resin

Designing a coextruded film with the right balance of properties for the final application, the converting process, and the blown film process can be a tricky juggling act that is easier with collaboration and the right equipment. Regardless of the number of layers, resins, outputs, or size your application requires, Davis-Standard has the right die platform to best suit your processing needs – which is the topic of the next post in the Blown Film Series.

Do you have questions or comments about this post? We would love to hear from you! Comments welcome below.

For blown film resin and equipment suggestions, do not hesitate to contact us and we’ll put you in touch with the right person based on application. E-mail marketing at marketing@davis-standard.com.

Cheers,

The D-S Connect Blog Team

Hello, I like your comprehensive articles like this one “What Resin is Right for You?” Blown Film Series Part II

Nevertheless, data might have been researched a little better. There are HDPE types going up to a density of 0.97, not just 0.94 which is the lowest level for a HDPE.

Hi Guenter, thank you so much for pointing this out. I reviewed with the Blown Film team and they have said it was a typo when writing the article. Thank you again for catching this. We are updating the blog now. The typo should actually read the following:

The description of HDPE should read:

· Highest density of the PE types due to lack of branching and high crystallinity levels – packs well in a 3-D array

· ρ = 0.93-0.97 g/cc