In the first blog of this series, we outlined oil change intervals. In this blog, we move on to the next step, flushing the gear reducer.

In the first blog of this series, we outlined oil change intervals. In this blog, we move on to the next step, flushing the gear reducer.

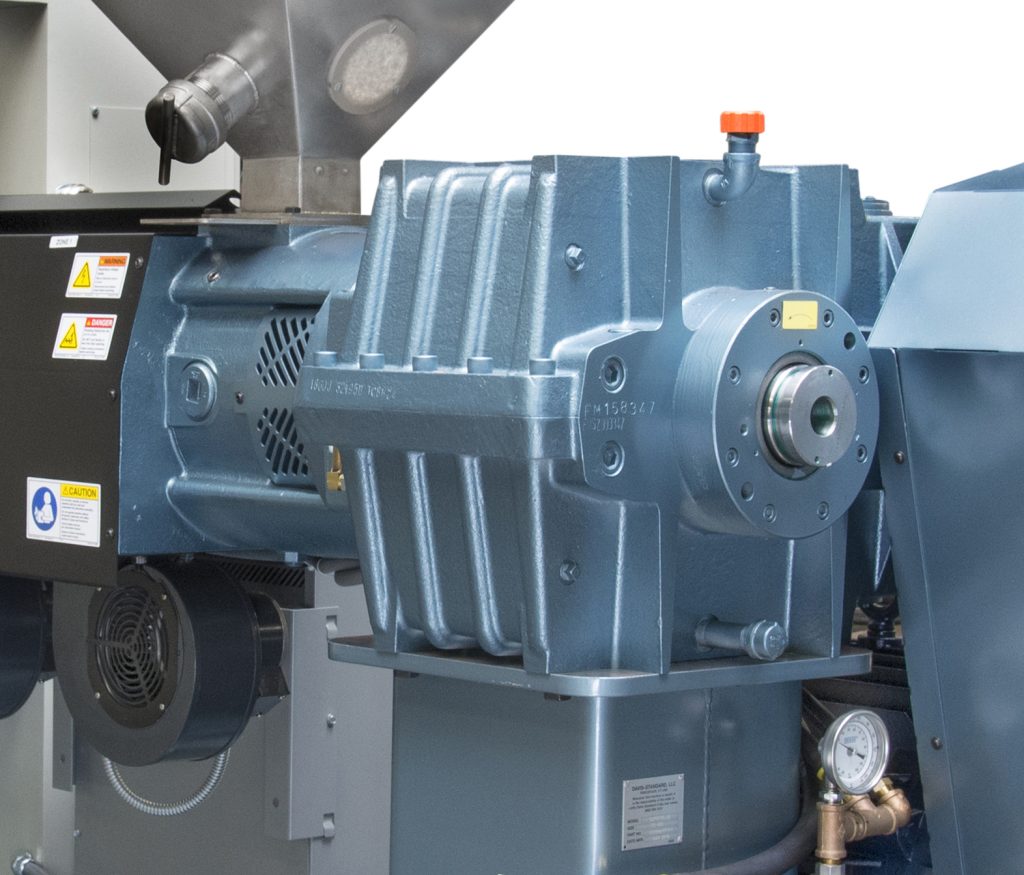

Always follow the maintenance information in the manual provided with your equipment. This blog summarizes general preventative maintenance for the gear reducer.

Guidelines for Flushing the Gear Reducer

Use an oil filter cart (with at least a 25-micron filter) for adding clean filtered oil to the reducer. An oil filter cart cleans new oil offline before filling the gear case, which reduces water, dirt, and wear particles that could be introduced to the lubrication system. In addition, a good oil-filtering system will reduce contaminants that impact the wear of machine parts and oil condition.

Flushing is a clean-fluid circulation process that removes water, chemical contaminants, air, and particulate matter resulting from construction, normal ingression, internal generation, or component wear.

Two methods for the oil change flush are described below. The first method uses a flushing oil specifically blended for flushing gear reducers. The second method uses clean operating oil for the flushing process.

Solvents should be unnecessary and are not to be used.

Method 1: Adding Flushing Oil to Existing Oil

This method requires the reducer to be run under no load with the feedscrew disengaged.

-

- Drain approximately 10 percent of the gear oil and add the same quantity of flushing oil.

- If equipped, replace the oil filter.

- After running the reducer for at least one hour, drain as much oil as possible from the gear reducer. If equipped with an oil cooling system, disconnect a low point hose (such as the suction hose connection at the pump) and drain the oil. Next, remove a drain plug from the heat exchanger shell and drain the heat exchanger.

- Replace any removed plugs and reconnect any oil hoses.

- Replace the oil filter and refill the reducer with clean filtered oil of the specified type and viscosity grade.

- Run the gear reducer at a slow speed to circulate oil through the cooling system. Recheck the oil level with the reducer stopped and add additional oil if necessary.

Method 2: Using Operating Oil

This method requires the reducer to run under no load with the feedscrew disengaged.

-

- Completely drain the oil after shutdown while the oil is warm. Then, add the same quantity of the clean, filtered replacement oil.

- If equipped, replace the oil filter.

- After running the reducer for at least one hour, drain as much oil as possible from the gear reducer. If equipped with an oil cooling system, disconnect a low point hose (such as the suction hose connection at the pump) and drain the oil. Next, remove a drain plug from the heat exchanger shell and drain the heat exchanger.

- Replace any removed plugs and reconnect any oil hoses.

- Replace the oil filter and refill the reducer with clean filtered oil of the specified type and viscosity grade.

- Run the gear reducer at a slow speed to circulate oil through the cooling system. With the reducer stopped, recheck the oil level and add additional oil if necessary.

In the next blog, we’ll cover oil selection. Stay tuned!

Have questions about this blog? Comment below.

Any other questions or inquiries, e-mail marketing.

Cheers,

The D-S Connect Blog Team