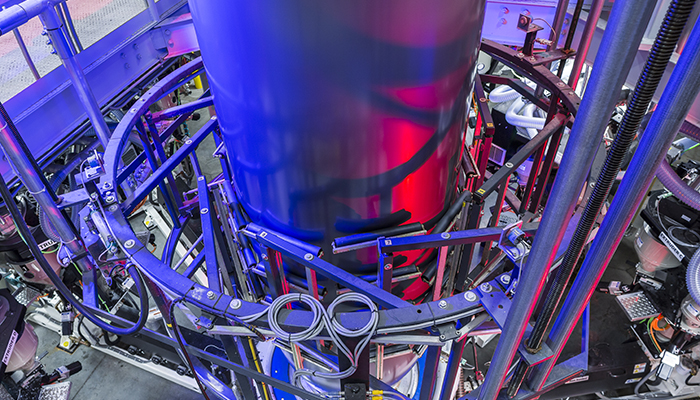

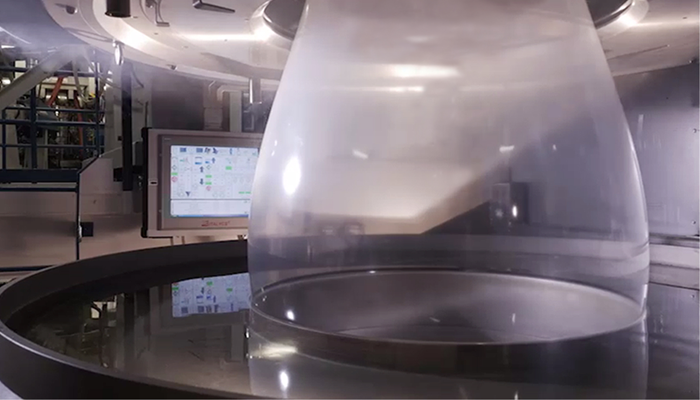

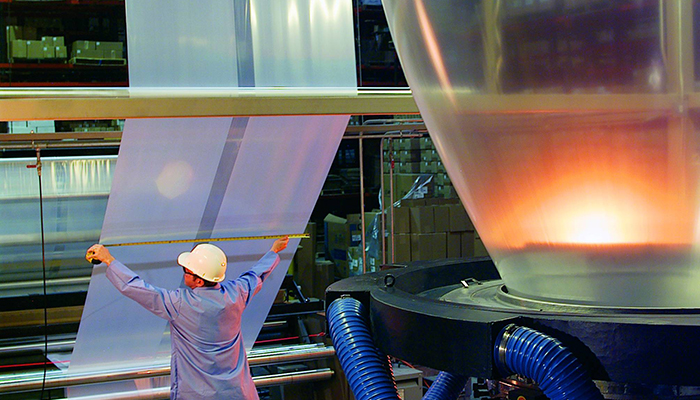

Davis-Standard supplies blown film extruders, extrusion lines and associated winders, dies and feedscrews for blown film processors around the globe. Our mono and multi-layer blown film technology is used for applications ranging from agriculture and greenhouse films, to packaging and shrink films, to stretch and collation films. Brampton Engineering, a blown film technology company for over 45 years that became a Davis-Standard company in 2018, is a leading provider of multi-layer AeroFrost® air blown and AquaFrost® water quenched film systems, film winding and many other film production solutions, particularly for food packaging.

In addition, to complete lines for co-extruded film up to 11 layers, the first water quenched film lines, and blown film lines for products up to 25m in circumference, we offer the widest range of components in the industry.

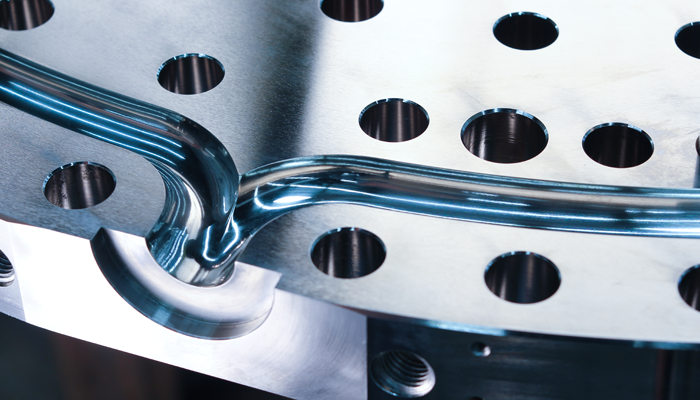

For new lines or retrofits, choose from SCD 4.0 pancake dies, Vertex side-fed cylindrical dies, Optiflow or Centrex center-fed cylindrical dies, with die lip diameters ranging from 4” to 100”.

Our portfolio of air rings includes WesJet dual lip, UpJet elevated dual lip and the newest Vector® single-inlet air ring with patent-pending Vector® dual lip for the easiest and most repeatable setups.

In addition to the proven Davis-Standard control systems, Brampton Engineering offers the ITALYCS® 5 line control system designed specifically for multi-layer blown film and AquaFrost®. Likewise, Brampton Engineering adds the FlexWin winder line to the extensive selection of winders offered by Davis-Standard.

Whether for innovative food packaging films, construction and agriculture stretch films, medical and hygiene barrier films, industrial films and bags for heavy-duty applications or flexible packaging, Davis-Standard and Brampton engineering blown film capabilities are unsurpassed.

Davis-Standard is the industry leader in developing innovative technology for large and wide blown film systems for industrial film and bag applications. There is no better blown film extruder for high output and low melt temperature than the MAC extruder with the DSB®II feedscrew. This extruder, specifically for blown film, leads to the best and most consistent melt quality (temperature uniformity to 2 degrees F and pressure variation <1%), which is necessary to achieve uniformity from large dies. Blown film die systems can oscillate up to 1.2 meters in diameter or remain stationary up to 2.1 meters in diameter. These systems produce controlled property films at wide widths with flat rolls. Typical Specifications

Applications - Industrial overwraps, jumbo bags, pallet hoods

Widths - 2 to 5 meters / 80 to 200 inches

Line Speeds - Up to 100 mpm / Up to 350 fpm

Thickness Range - 20 to 300 micron / 0.8 to 12 mil

Finished Roll Diameter - Up to 1.5 meters / Up to 60 inches

Output - 1000 to 2300 kg/h / 2000 to 5000 pph

Coextrusion - Mono, three and five layer systems

Features - Gusseting and folding, MAC extruders, DSB® screws, Centrex dies, WesJet TPC air ring, surface and dual turret winders, small and large roll winders, full automation

Davis-Standard's blown film flexible packaging solutions for high-speed converting machinery lines are unsurpassed. This is especially true in the area of barrier films where roll geometry, thickness and layer uniformity lead to faster conversion speeds on pouch lines, FFS machines and laminating lines. Uniform layers enable cost-efficient use of expensive materials, and our blown film lines have proven effective in producing economical coextruded structures. Advantages such as stationary die systems, oscillating haul-offs, and roller-collapsing frames produce flat, smooth film and rolls. Our blown film systems are also known for consistent symmetric and asymmetric films.

Typical Specifications

Applications - Barrier films

Machine Configuration - 2380 mm 7-layer / 94-inch 7-layer

Nominal Layer Structure - 25 / 10 / 10 / 10 / 10 / 10 / 25

Die Diameter - 400 to 560 mm / 16 to 22 inches

BuR - 1.8 - 3.0:1 1.8 - 3.0:1

Max Web Width - 2300 mm / 90 inches

Typical Output - 350 - 575 kg/hr / 660 - 1265 lbs/hr

Thickness Range - 20 - 200µ / 0.8 - 8.0 mil

Materials to be Processed - LD, LLD, EVA, EVOH, PA, PP, lonomer, Tie

Davis-Standard understands the primary goal of can liner systems is output. Rates over 25 ppi and increased uptime are trademarks of our industry-leading blown film systems. Our die systems are stationary with oscillating haul-offs so that jumbo rolls can be made for off-line converting. Other advantages include:

- Super air-cooled MAC extruders with a high-volume suction blower concept for superior cooling and low maintenance

- Pre-wired control panels mounted on extruder base to reduce installation time

- DSB®II feedscrews with high output mixing

- Vertex dies for easy operator access and excellent uniformity to <5% before auto adjustment

- Triple lip air rings and IBC for high cooling rates and increased bubble stability

- Collapsing frames available as wood, covered slats or roller with partial or full gussets

- Surface winders for large roll diameters

Typical Specifications

Applications - Trash bags, kitchen bags, composting bags

Widths - 1 to 3 meters / 40 to 120 inches

Line Speeds - Up to 120 mpm / Up to 400 fpm

Thickness Range - 12 to 75 micron / 0.5 mil to 3 mil

Finished Roll Diameter - Up to 1.5 meters / Up to 60 inches

Output - 500 to 700 kg/hr / 1000 to 2000 pph

Configurations - Single, dual and quad die systems

Features - Integrator full control system, Gravimetric layer ratio control, MAC extruders, DSB® screws, Vertex dies, WesJet air ring, surface

Davis-Standard is a global extrusion leader in flexible packaging with lamination lines capable of 2000 feet per minute. We understand the needs for high-speed converting machinery, especially in the area of laminating films where roll geometry and layer uniformity leads to faster speeds on converting and laminating lines. Uniform layers enable cost-efficient use of expensive materials, and our lines have been effective in producing economical coex structures. Advantages such as stationary die systems, oscillating haul-offs, and roller-collapsing frames produce flat, smooth film and rolls. Our systems are also known for consistent symmetric and asymmetric films.

Typical Specifications

Applications Extrusion coating, dry bond laminating, metalizing or solution coating machines

Widths - 1.5 to 3 meters / 60 to 120 inches

Line Speeds - Up to 120 mpm / Up to 400 fpm

Thickness Range - 12 to 50 micron / 0.6 to 2 mil

Finished Roll Diameter - Up to 1.25 meters / Up to 50 inches

Output - 500 to 1200 kg/hr / 1000 to 2500 pph

Coextrusion - Three and five-layer systems

Features - Integrator control system, gravimetric layer ratio control, MAC extruders, DSB® screws, Vertex dies, WesJet AutoPro air ring, surface and dual turret winders, small and large roll winders, full automation

Davis-Standard understands stretch wrap systems. Whether cast or blown film, our technology is applied to all components. Roll geometry and unique small roll winders efficiently allow for high production rates by providing reliable, consistent automated roll handling. Die systems are stationary up to 1-meter in diameter. Oscillating haul-offs and roller collapsing frames produce flat, smooth film and rolls. Oscillating die and stationary haul-offs are also available. These systems produce symmetric and asymmetric films.

Specific to agricultural stretch films, our technology is focused on uniform quality and thickness. This provides excellent stretch properties with consistent cling levels, strong puncture resistance, high load retention for bale integrity, low oxygen and water permeability.

Typical Specifications

Applications - Bale wrap: 500 mm / 750 mm reels

3-Layer Configuration - 90 / 150 / 90 mm / 3 1/2-inch / 6-inch / 3 1/2-inch

5-Layer Configuration - 75 / 90 / 130 / 90 / 75 mm / 3-inch / 3 1/2-inch / 5-inch / 3 1/2-inch / 3-inch

Nominal Layer Structure - 15 / 70 / 15 or 10 / 20 / 40 / 20 / 10

Die Diameter - 790 - 850 mm / 31 - 34 inches

BuR - 2.45 - 2.65:1

Max Web Width - 3300 mm / 130 inch

Typical Output - 750 - 900 kg/hr / 1650 - 1980 lbs/hr

Thickness Range - 15 - 38µ / 0.6 - 1.5 mil

Materials to be Processed - LD, LLD, mLLD, EVA, and PIB injection

When you think of agricultural (ag) films, think Davis-Standard. We offer extensive knowledge and proven solutions for large and wide blown film for a range of agricultural applications. There is no better extruder available for high output and low melt temperature than the MAC extruder with DSB®II feedscrew. This extruder, designed for blown film applications, leads to the best and most consistent melt quality (temperature uniformity to 2 degrees F and pressure variation <1%), which is necessary to achieve uniformity from large dies. The die systems can oscillate up to 1.2 meters in diameter or remain stationary up to 2.1 meters in diameter. These blown film systems produce controlled property films at wide widths with flat rolls. Typical Specifications

Applications - Groundcovers, pond liners, mulch films, fumigation films, drop cloths, reflective films, greenhouse films, textured and smooth

Widths - Bubble circumferences from 5 to 25 meters /Bubble circumferences from 16 to 80 feet

Line Speeds - Up to 100 mpm / Up to 350 fpm

Thickness Range - .03 to 3 mm / 1.5 to 120 mil

Finished Roll Diameters - Up to 750 mm / Up to 30 inches

Output - 1,000 to 500 kg/hr / 2,000 to 10,000 pph

Coextrusion - Mono, three, five and seven-layer systems

Features - Gusseting and folding, MAC extruders, DSB® screws, Centrex dies, WesJet air ring, surface and dual turret winders, small and large roll winders, full automation

Food Packaging

Brampton Engineering has specialized in multi-layer co-extrusion AeroFrost® film systems for over 45 years. The flat pancake-style SCD® 4.0 die offers not only the lowest residence times for the middle and outer layers and the fastest resin changeovers, but can also be customized with thermal isolation between layers to minimize overheating thermally sensitive resins such as EVOH in proximity to much hotter nylon layers in high-barrier film structures. Paired with the Vector® air ring and ITALYCS® control system, SCD is the most flexible die choice for making a wide range of different film structures with fast job changeovers and less frequent die cleaning.

Typical Specifications

Applications – lamination films, vacuum skin films,

Coextrusion - Three to 11 layer systems

Film Widths - 760 to 2794 mm / 30 to 110 inches

Thickness Range - 25 to 250 micron / 1 to 10 mil

Resins – LDPE, LLDPE, HDPE, EPE, PA, EVOH, EVA, PP, PETG, ionomers, plastomers, etc.

Output – 180 to 1000 kg/h / 400 to 2200 pph

Features – SCD 4.0 die with thermal isolation, Vector single inlet air ring, FlexWIN turret winder, ITALYCS 5 blown film control system

Want to learn more? Click to Contact Us.

Davis-Standard offers a comprehensive line of laboratory and pilot-scale equipment designed to meet blown film process requirements for product development, polymer research, material testing, and validation. This includes extruders, process controls, feedscrew technology, and downstream equipment. Single or multi-layer laboratory systems are available as well as individual components. Sturdy and reliable construction simulates production performance and accuracy. Advantages include:

- Cooling towers in fixed or adjustable configurations up to 20’ elevation

- Nip station width range from 12”-24”

- Bubble guides available as single or multi-level

- Collapsing frame with wooden slats or non-stick rollers

- Air cooling rings supplied as single or dual-lip

- Spiral mandrel dies from 1”-3”

- Dedicated system includes complete line on common base

- Options: lay-flat width control, web break detection, slitting and gel detection

Typical Specifications

Widths – 4”-24”

Line Speeds –100-100fpm

Thickness Range – .001”-.010”

Output – 5-50 lbs/hr