09-10-2018

How important are feedscrews and barrels to profitability? When you consider product quality, target outputs and overall process performance, the answer is VERY important.

Read More >

30-09-2018

As the healthcare segment continues to grow worldwide, it is vital that equipment meet or exceed specific criteria to support customer success.

Read More >

16-09-2018

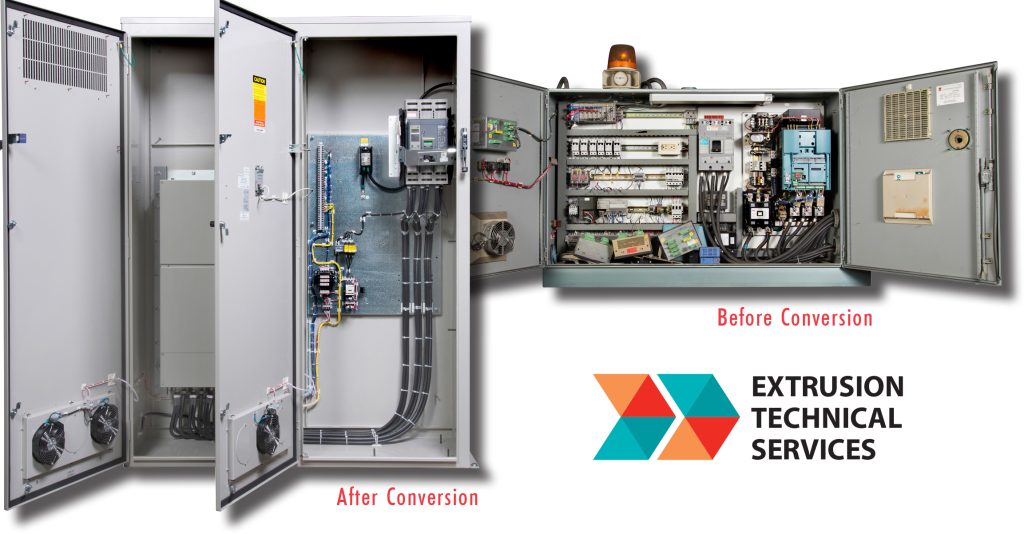

As we seek to help customers improve outputs and operating efficiency, we look at every extruder component. Two components of paramount importance are the extruder drive and motor. If your extruder is running on an outdated DC drive and motor, you may want to consider the benefits of an AC package to improve your bottom line. The environmental benefits of AC drives and motors combined with production cost savings create a win-win. For some processes, the savings can be so substantial that the initial investment can be returned within a few years. The power savings and superior efficiency of AC technology are widely proven. This is especially true in the European marketplace, which has led the industry in adopting and developing power-saving solutions. A trial at Davis-Standard’s Technical Center showed AC systems use 5 to 15 percent less power than a DC system. Davis-Standard’s AC motor conversion packages are well suited to most extrusion processes and have low-cost, three-phase AC induction technology. Minimal maintenance, improved accessibility, and greater durability for varied application loads all contribute to production efficiency. If you have aging equipment and are experiencing less than optimal production rates, let us know if we can help you. Installing an AC package may be a viable option before a major breakdown occurs. Several U.S. states offer rebates to manufacturers that install green equipment. Check your local regulations to see if you’re eligible. For more information or to inquire about making the switch to AC drive and motor technology, please contact marketing@davis-standard.com. Cheers, D-S Connect Blog Team

Read More >

16-09-2018

We’re happy you’re here! Connecting with you, our customers, is our mission. What better way than posting valuable insights and information focused on equipment health, improved processing, new trends, technological advances and more. You’ll hear from various team members on a range of subjects related to extrusion and converting applications. We also encourage you to contact us directly at marketing@davis-standard.com if there is a specific topic you’d like us to address. We hope you’ll visit often and that connecting via this blog will be beneficial to your manufacturing operation. Here’s to maximum productivity and industry excellence! Cheers, The D-S Connect Blog Team

Read More >